This article originally appeared in the April 2017 issue of Today's Medical Developments. It was the cover story entitled: "Micro-Precision Machining" Matt Saccomanno’s Microconic collet-type workholder for small part machining was inspired by his experience in a Swiss screw-machine job shop. By Elizabeth Modic

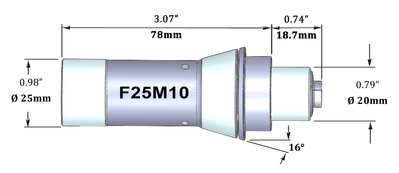

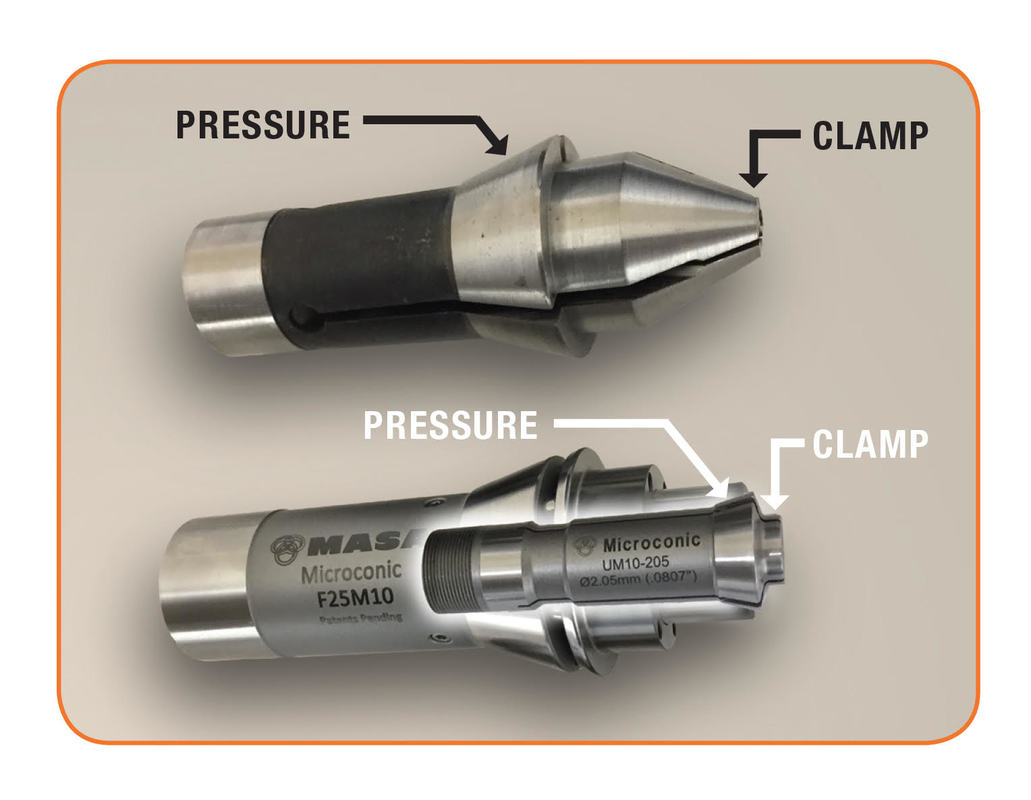

Cartridge & Collet“The Microconic system consists of a cartridge and collet, with the cartridge fitting in the machine just like a standard legacy collet,” Saccomanno says. “The cartridge, a self-contained precision mechanism using the machine’s standard collet closing function, brings Microconic features to any machine.” Cartridges fit an expanding range of machines, and are currently available for those using TF20, TF25, or 5C collets. Microconic UM10 collets fit into the cartridge to hold the workpiece and because of the design and closing action, it is inherently more accurate and consistent than traditional collets.  The F25M10 Cartridge is compatible with spindles that accept Schaublin F25, Southwick & Meister TF25, KEB (MasWerks) MC25, and Hardinge TF25 / 4613 collets. The F25M10 Cartridge is compatible with spindles that accept Schaublin F25, Southwick & Meister TF25, KEB (MasWerks) MC25, and Hardinge TF25 / 4613 collets. The F25M10 Cartridge is compatible with spindles that accept Schaublin F25, Southwick & Meister TF25, KEB (MasWerks) MC25, and Hardinge TF25 / 4613 collets. “The origin of the word Microconic alludes to the precise way in which the collet closing taper is formed to cancel the effects of heat-treat warp and grind tolerances, providing concentricity every time,” Saccomanno explains. “ There are two basic types of Microconic collets – standard and over-grip, and both types fit in any of our cartridges. Our over-grip collets deliver rigidity, concentricity, and the ability to open 4mm (0.156") larger than the gripping diameter.” Explaining that the patented design of the system enables the improved over-gripping performance, Saccomanno notes – from his own experience – that this is impossible to do in a legacy collet system alone. Included with the over-grip collet is an ejection guide sleeve blank for ejecting the part from the collet – an often challenging task because the larger head of the part inside the collet can get stuck if not securely guided out when opening. Saccomanno says the system alleviates challenges machinists face when setting up for small part machining by addressing the limitations of legacy collet systems. “Collet-type workholding has a history of being the best method to hold small workpieces in production situations, because of rapid closing action, high clamping force, rigidity, and accuracy. To grip various workpieces of different diameters, a specifically sized collet is pre-made to match the gripping diameter,” Saccomanno says. “The exterior size and shape of the collet does not change, only the internal diameter of the gripping surface. So, a collet system for any given machine must be made large enough to fit the maximum workpiece diameter capacity of the machine. The result is the collet mechanism is designed to handle the largest workpieces, which means it is excessively forceful and bulky when used for the smaller workpieces. Smaller parts get sacrificed, because they typically require a higher degree of accuracy and the workholding is more critical.” Prescott explains that there are three ways the Microconic cartridge optimizes machines for small parts. Precision control – The cartridge provides complete internal control of collet closure, regardless of how forceful the machine’s mechanism is. Micrometer-graduated adjustment of the precise amount of collet closure, set with the MicroGrad wrench, allows even the most fragile parts to be held securely and without damage. The closure setting can be recorded on the set-up plan and accurately repeated without relying on the feel or experience of the machinist. Improved Part AccessWith small parts reaching the part with small cutting tools can be difficult due to interference with relatively large spindle noses. Legacy systems often use an extended nose collet to give adequate clearances, causing problems with lack of concentricity while the flexing of the long collet jaws leads to poor rigidity and holding power.

Maximum rigidity is achieved, so the part can be held securely without too much force, allowing operations that legacy collets can’t perform. Rapid setup The collet can be changed and adjusted entirely from the front of the spindle nose. Also, the concentricity and rigidity means no troubleshooting or swapping of collets to find one that runs true. It is guaranteed that the system will not add more than 0.0002" (5µm) total indicated runout. When making the change to the system, machinists will remove the legacy collet (and spring, if any), and install the Microconic cartridge the same way a legacy collet would be installed. The Microconic collets then thread in from the front of the cartridge, which makes collet changing easier. When the cartridge is first installed, the machinist should use a dial test indicator to measure the runout of the cartridge nose, which is ground to gage-like tolerances. “If there is any runout, it is a result of the machine spindle condition and should be diagnosed as required. Usually this just involves a very thorough cleaning of the seating surfaces, but may also be due to production wear or damage,” Prescott notes. “The key here is that concentricity issues can be properly diagnosed and corrected right away, without having to run parts or try multiple collets. Once corrected, concentricity will be good every time, saving hours of troubleshooting during future setups.” About the author: Elizabeth Modic is the editor of Today’s Medical Developments and can be reached at [email protected] or 216.393.0264.

0 Comments

Leave a Reply. |

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed