|

OCEANSIDE, CA. - At IMTS 2022 we where visited by the great folks at GIE Media, Inc. who publish Today's Medical Developments, Aerospace Manufacturing and Design and Today’s eMobility. They asked Matt Saccomanno, the inventor of the Microconic system to give them an on-camera overview of our products and how they work. As you probably already know, Masa’s Microconic Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface in your Swiss type CNC screw machine. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of shifting part operations from the main to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. At IMTS 2022, we expanded our Microconic line of swiss type CNC machine workholding. The new push type F15M5 and F16M5 cartridges replace the standard TF15 and TF16 collets in your CNC spindle. This enables you to use the newly introduced Microconic UM5 collet series with the Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. The off-the-shelf Microconic system concentricity of the cartridge and collet system combination is guaranteed to be within 5µm (0.0002") in production use. Both the F15M5 and F16M5 cartridges are a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F15M5 cartridge is compatible with spindles that accept Schaublin F15 76-580, E120, Southwick & Meister TF15 and Hardinge TF15 / 4607 collets, while the F16M5 cartridge is compatible with spindles that accept Schaublin F16 76-1076, E1212, Southwick & Meister TF16 and Hardinge TF16 / 4609 collets. Along with the new smaller cartridges comes a comprehensive series of UM5 collets that are ideally suited for small diameter part sizes ranging from 0.2mm/.008" to 5.5mm/.217" in diameter. These are available in regular type UM5 collets as well as all three types of Microconic's T, V and W type Over-Grip collets. Masa Tool offers the most unique variety of over-grip collets in the industry. And yes, if you listened closely to the video, you heard correctly, Matt spilled the beans on the new product that we'll be releasing next: The F13M5 Cartridge. And after that, we're going to heed that advise of "go big or go home. Yea, that was a spoiler alert.  The things that seems to excite Swiss machinists the most is our Micrograd™ wrench. The Micrograd Dial Wrenches provides a method of precisely setting clamping pressure on both the regular Microconic collets and on all series of Microconic over-grip collets. It can be adjusted in an infinite number of increments between the metric graduations of 0,02mm and inch/imperial graduations of .001" With the Micrograd Dial you can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

0 Comments

The standard Microconic collets will help with bone screws and other bone implants by allowing a firm grip on the threaded exterior without causing damage, and yet holding it so much more rigidly that they will be able to do heavy operations in the sub spindle. This includes operations like blind hole broaching. Set ups are quicker and more repeatable with Microconic. With the Microgram Dial Wrench You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

Matt goes on to explain how the Microconic System solves all of the problems with traditional pickoff collet with a guaranteed 0002" TIR accuracy and ships everything from stock within two days of placing an order! Matt Saccomanno, the Co-Founder of Masa Tool and inventor of the Microconic Workholding sytem will talking about process innovations in the metalcutting manufacturing industry during the International Manufacturing Technology Show, IMTS, in September at McCormick Place in Chicago, IL. Swiss-type CNC machines have gained in capability and demand as the machined components they produce are trending toward higher precision and micro-sized features. As the machines have become more sophisticated, the underlying basics of workholding remained unchanged until recently.

This presentation is an overview of new developments as well as traditional approaches with relevance to today’s highly capable sliding headstock “Swiss-type” CNC turning centers. The goal is to summarize best-practices for optimizing use of both main and sub-spindle to maximize productivity and overall equipment effectiveness. The material presented is useful for machinists, CNC programmers, tool crib personnel, manufacturing engineers, estimators, and hands-on managers. If you would like to reserve your spot in this technical presentation and discussion please click the below button. OCEANSIDE, CA - Masa Tool has just released the newest product in the Microconic line of cartridges for swiss machine workholding. The NEW push type F201M10 Cartridge replaces the Tornos F20-201 collet in your CNC spindle. This enables you to use our Microconic collets to achieve concentricity guaranteed to be within 5µm (0.0002") in production use. The F201M10 Cartridge is a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F201M10 Cartridge is compatible with spindles that accept F20-201 collets including DIN 136E, Meister Swiss 136E, Schaublin F20 (76-201), Southwick & Meister F20-201, KEB (MasWerks) MC20-201, Hardinge F20-201 / 4709 collets. Masa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of moving part operations to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. F201M10 Cartridge Features

Set ups are quicker and more repeatable with Microconic™. You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

How to use the Micrograd™ Face Dial Wrench

For a complete set of instructions please see our installation procedures for more details on how to set up and replicate your clamping pressure on every machine in your shop.

OCEANSIDE, CA. Masa Tool has expanded their line of Microconic over-grip collets to include a new style called a "T-type." The T-type over-grip collet has a longer gripping surface than the original W-type. We designed it specifically for longer parts such as bone screws with wide pitch threads.

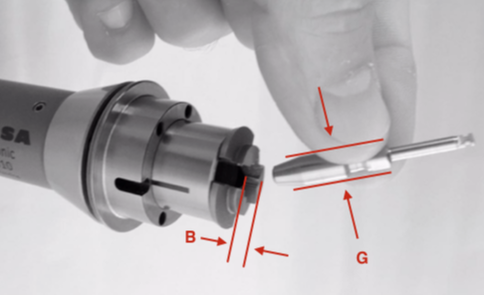

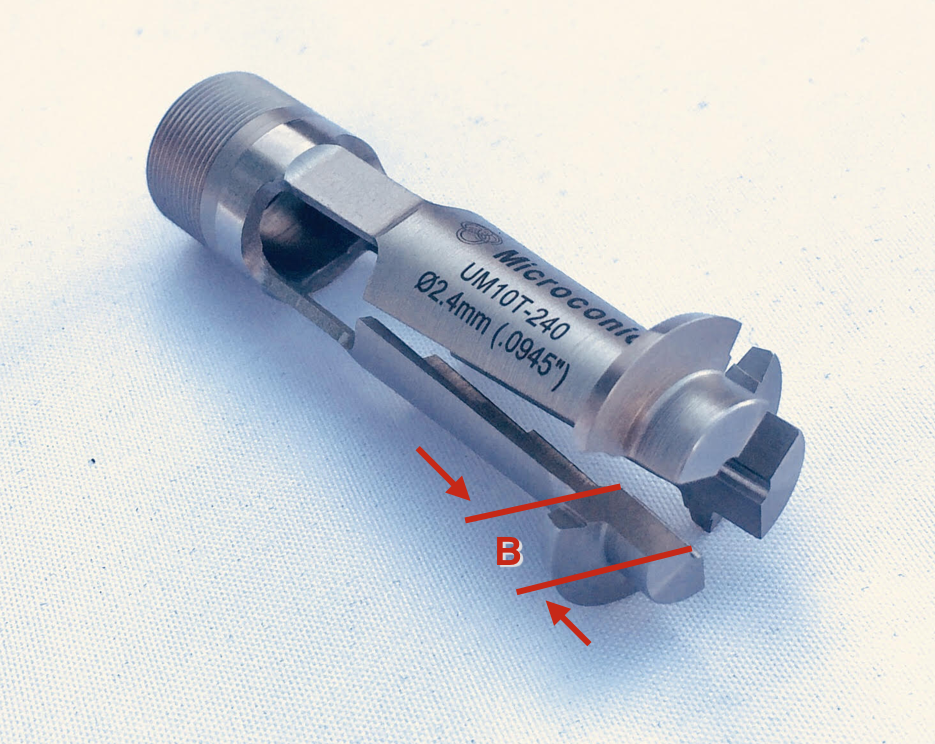

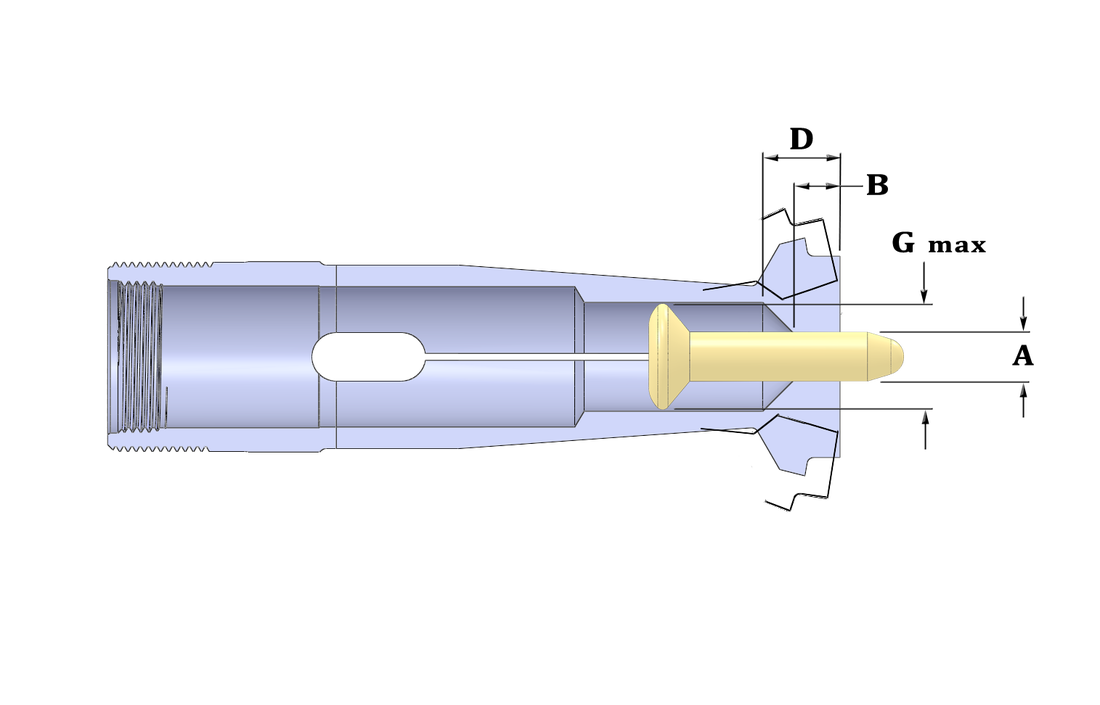

But, in some cases, with longer parts, the land width "B" needs to be longer to support the workpiece properly. Masa's new T-type collet provides the solution for longer workpiecesTypically with over-gripping applications, a shorter land length/clamping pad length/grip length is desired because of limited space available to hold the workpiece behind the enlarged head or flange that it is reaching over. That is what our original W-type collet was optimized for. However, with longer parts, with more surface area for clamping and gripping room, a longer land length is often preferred to provide more stability to support the longer length workpiece.

Microconic T-Type Over-grip Collet features

If you've tried other companies overgrip collets with poor results, Microconic over-grip collets will allow you to do things you might have thought impossible!

Due to the extreme opening capability of our overgrip collets , workpiece ejection must be very reliable to prevent a part from becoming stuck in the slots of the collet. Therefore we have developed the Microguide™ ejection guide sleeve to prevent parts from falling inside the collet instead of ejecting into the part catcher.

Masa Tool is introducing its Microconic workholding system for use in subspindle Swiss-type machine operations, enabling the operator to switch operations from the main to the subspindle so that usage is balanced. Masa Tool is introducing its Microconic workholding system for use in subspindle Swiss-type machine operations, enabling the operator to switch operations from the main to the subspindle so that usage is balanced. This capability is said to reduce cycle time in ways that are not possible with conventional collets. The Microconic system consists of two primary components: a cartridge that fits in the machine’s standard TF20, TF25 or 5C collet closer, and the collet itself, which fits into the cartridge. Each cartridge model has a solid extended nose and can accept both regular and over-grip collets. The over-grip collets open up to 0.157" (4 mm) larger than the clamping diameter. The Microconic cartridge’s extended nose design directs all of the chucking pressure directly over the workpiece for concentricity and rigidity. Total indicated runout (TIR) for the Microconic system is guaranteed at 0.0002" (5 µm) at the workpiece, absent any runout introduced by the machine structure or other elements of the setup. The system capacity ranges from 0.008" to 0.394" (0.2 to 10 mm) in diameter, with all sizes available from stock.

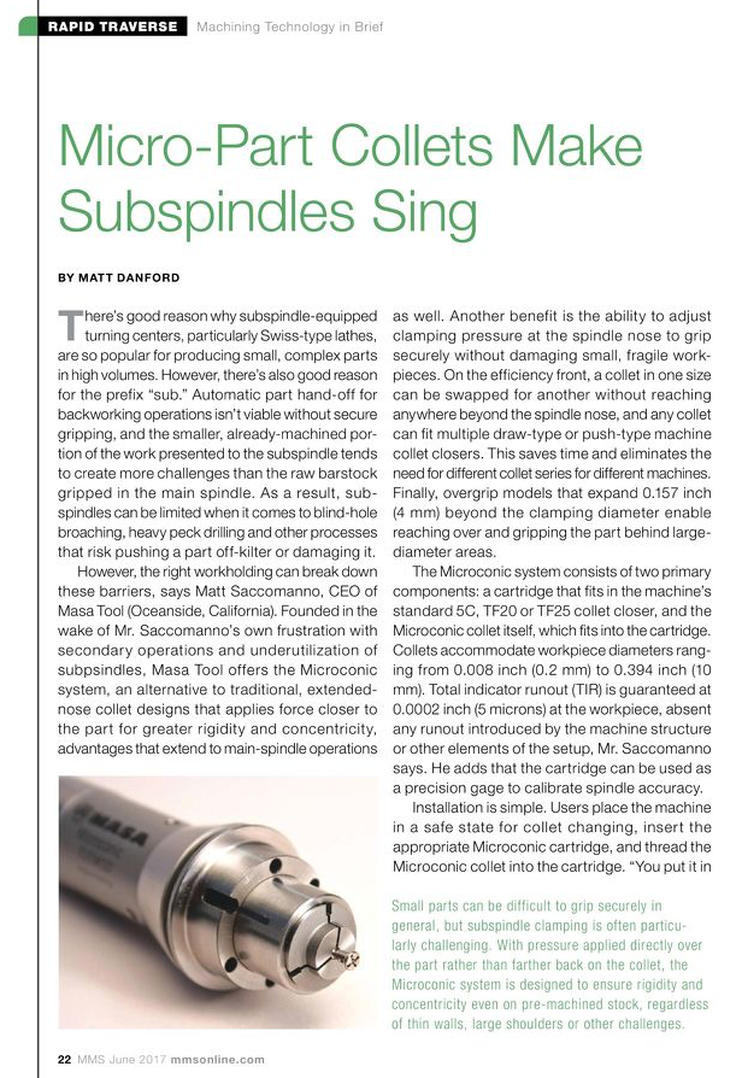

We got a very unexpected present in the mail this past week! We where very excited to learn that our Microconic workholding system for small diameter part machining was featured in the Rapid Traverse section of the June 2017 issue of Modern Machine Shop!!! We've got pictures of the article below in case you don't currently subscribe to Modern Machine Shop. You can also download a PDF copy of the entire June issue below in the link. It starts on Page 25 of the PDF download. If you have the print edition it's on Page 22, or you can just read thought the screen shots below. We want to really extend a very big THANK YOU to Matt Danforth at Modern Machine Shop who wrote this article. Matt really did an awful lot of work learning about the various features of our system. We know there where many many hours that he spent to develop this story just from the sheer number of follow up questions and conversations. We really have an awful lot of respect for the entire MMS team and the effort they put into getting their story's "just right".

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

||||||||||||||||||||||||||

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed