|

OCEANSIDE, CA. - At IMTS 2022 we where visited by the great folks at GIE Media, Inc. who publish Today's Medical Developments, Aerospace Manufacturing and Design and Today’s eMobility. They asked Matt Saccomanno, the inventor of the Microconic system to give them an on-camera overview of our products and how they work. As you probably already know, Masa’s Microconic Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface in your Swiss type CNC screw machine. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of shifting part operations from the main to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. At IMTS 2022, we expanded our Microconic line of swiss type CNC machine workholding. The new push type F15M5 and F16M5 cartridges replace the standard TF15 and TF16 collets in your CNC spindle. This enables you to use the newly introduced Microconic UM5 collet series with the Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. The off-the-shelf Microconic system concentricity of the cartridge and collet system combination is guaranteed to be within 5µm (0.0002") in production use. Both the F15M5 and F16M5 cartridges are a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F15M5 cartridge is compatible with spindles that accept Schaublin F15 76-580, E120, Southwick & Meister TF15 and Hardinge TF15 / 4607 collets, while the F16M5 cartridge is compatible with spindles that accept Schaublin F16 76-1076, E1212, Southwick & Meister TF16 and Hardinge TF16 / 4609 collets. Along with the new smaller cartridges comes a comprehensive series of UM5 collets that are ideally suited for small diameter part sizes ranging from 0.2mm/.008" to 5.5mm/.217" in diameter. These are available in regular type UM5 collets as well as all three types of Microconic's T, V and W type Over-Grip collets. Masa Tool offers the most unique variety of over-grip collets in the industry. And yes, if you listened closely to the video, you heard correctly, Matt spilled the beans on the new product that we'll be releasing next: The F13M5 Cartridge. And after that, we're going to heed that advise of "go big or go home. Yea, that was a spoiler alert.  The things that seems to excite Swiss machinists the most is our Micrograd™ wrench. The Micrograd Dial Wrenches provides a method of precisely setting clamping pressure on both the regular Microconic collets and on all series of Microconic over-grip collets. It can be adjusted in an infinite number of increments between the metric graduations of 0,02mm and inch/imperial graduations of .001" With the Micrograd Dial you can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

0 Comments

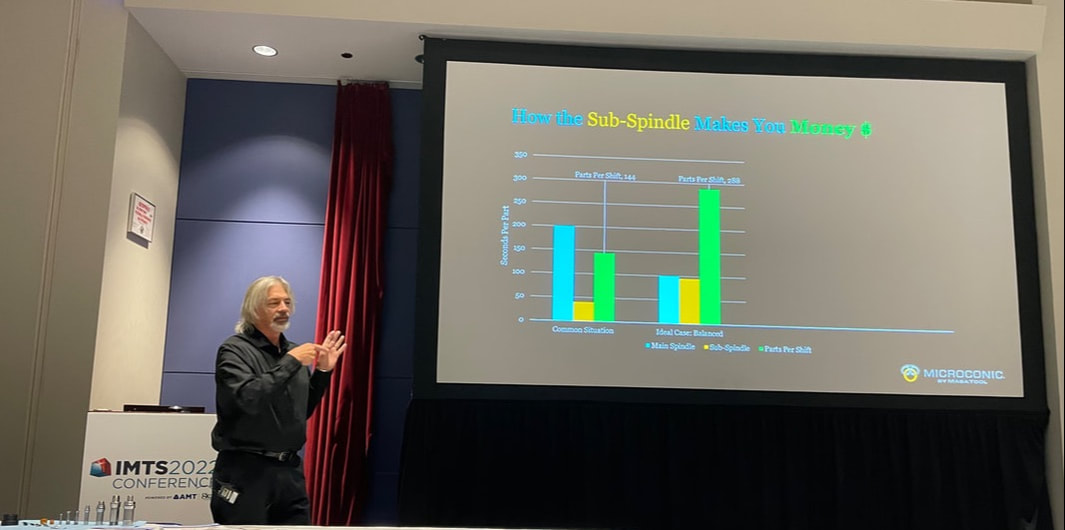

CHICAGO, IL. - The 2022 IMTS show was truly a great success for our team at Masa Tool! It was great to be back in Chicago and seeing our supply chain partners, customers and media in -person again! Our CEO and chief executive innovator, Matt Saccomanno held a seminar entitled "Boosting Profits from Swiss-type Machines by Better Use of the Sub-Spindle." It was a presentation "of new and advanced techniques for gaining productivity from Swiss-type CNC machines, with an emphasis on maximizing utilization of the machine’s counter-spindle (“sub-spindle”)." Well, that's quite a mouthful! Matt explained that essentially the sub-spindle is rarely used at more than 20% efficiency, which is a huge waste of productive capacity! "You've got a fully capable machine within a machine that you're not maximizing the use of!" Chip Prescott and David Atkinson manned our booth with the help of many of our great manufacturers agents. It was terrific that our reps brought so many of our customers over so we could finally meet them in person! GIE Media, Inc. who publish Today's Medical Developments, Aerospace Manufacturing and Design and Today’s eMobility spent some time in our booth getting a video overview of our products one day. A really special thank you to Lori Beckham, the editor of Today's Medical Developments and Austin DiPaolo for stopping by to say hello. Lori, in conjunction with Bernie Martin, wrote the "Improving small medical part manufacturing" article that appeared last May in Today's Medical Developments. The next day the Lori Beckman, the editor of Production Magazine stopped by with our friend Rachel Wallis and then brought a video crew by to do an interview and overview. Lori wrote the an article "Swiss Shop’s Choice of Collets Facilitates Backworking" this past June. Production magazine is owned by Gardner Publications and we will be at their PMTS show next April. So if you didn't;t make it to IMTS get us on your calendar for the spring of 2023! We're looking forward to seeinghow the videos turned out because we wanted to answer some of the commonly asked questions that we get when talking to Swiss machinists. We shared our booth with the guys from Swiss tooling producer, Dunner They are one of our best European distributors and they where featuring their DunnAir self adjusting high precision guide bushing. At the end of the show, everyone was exhausted but really super excited to meet some many of our customers. Thanks so much for visiting us at the IMTS 2022. Our next show is in April at PMTS. If you missed us in Chicago, be sure and meet us in Cleveland! FOR IMMEDIATE RELEASE  Masa Tool's NEW products being introduced at IMTS 2022: The F15M5 & F16M5 cartridges and accompanying NEW UM5 collet series which includes over-grip collets and Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. CLICK THIS IMAGE TO ADD MASA TOOL'S IMTS BOOTH TO YOUR SHOW PLANNER OCEANSIDE, CA - Masa Tool has expanded their Microconic line of swiss machine workholding. The new push type F15M5 and F16M5 cartridges replace the standard TF15 and TF16 collets in your CNC spindle. This enables you to use the newly introduced Microconic UM5 collet series with the Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. The off-the-shelf Microconic system concentricity of the cartridge and collet system combination is guaranteed to be within 5µm (0.0002") in production use. F15M5 and F16M5 CartridgesBoth the F15M5 and F16M5 cartridges are a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F15M5 cartridge is compatible with spindles that accept Schaublin F15 76-580, E120, Southwick & Meister TF15 and Hardinge TF15 / 4607 collets, while the F16M5 cartridge is compatible with spindles that accept Schaublin F16 76-1076, E1212, Southwick & Meister TF16 and Hardinge TF16 / 4609 collets. UM5 Microconic ColletsAlong with the new smaller cartridges comes a comprehensive series of UM5 collets that are ideally suited for small diameter part sizes ranging from 0.2mm/.008" to 5.5mm/.217" in diameter. These are available in regular type UM5 collets as well as all three types of Microconic's T, V and W type Over-Grip collets. Masa Tool offers the most unique variety of over-grip collets in the industry. Micrograd UM5 Dial WrenchA full set of UM5 accessory products has also been introduced including a a UM5 series of Microguide EGS™ ejection guide sleeves and a new UM5 Micrograd™ Dial Wrench which is included with the purchase of any of the Microconic Cartridges. Mircrograd Dial Wrenches for the UM5 collets are now available in both metric, CW5-M, and imperial increments CW5-E. The Micrograd™ Dial Wrenches provides a method of precisely setting clamping pressure on both the regular Microconic collets and on all series of Microconic over-grip collets. It can be adjusted in an infinite number of increments between the metric graduations of 0,02mm and inch/imperial graduations of .001" With the Micrograd Dial you can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel". Microconic: Game Changing Technology for Small PartsMasa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of shifting part operations from the main to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. These new cartridges, collets and accessories will be demonstrated for the first time at IMTS 2022 in the West Building, Level 3 — 432163 — Tooling & Workholding Systems IMTS Press BriefingJoin Masa Tool at Booth 432163 West Building, Level 3 TUESDAY SEPTEMBER 13 AT 3:30PM central time We will introduce our NEW Microconic products for Swiss-type CNC Workholding! Featuring Masa Tool's expands its Microconic system at IMTS 2022: The F15M5 & F16M5 cartridges and accompanying NEW UM5 collet series which includes over-grip collets and Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure

Be sure to join Matt Saccomanno, President of Masa Tool, presentation on boosting profitability by taking advantage of improvements in sub spindle workholding on Swiss-style CNC Machines. IMTS Conference: Boosting Profits from Swiss-type Machines by Better Use of the Sub-Spindle Wednesday, September 14 • 10:00 AM - 10:55 AM Central This is a presentation of new and advanced techniques for gaining productivity from Swiss-type CNC machines, with emphasis on maximizing utilization of the machine’s counter-spindle (“sub-spindle”). Essentially a fully capable machine within a machine, the sub-spindle is rarely used at more than 20% efficiency, which is a huge waste of productive capacity. Most of the roadblocks to increased usage stem from the limitations of traditional workholding. The presentation is loaded with real-life examples and practical do-right-now techniques. Swiss-type CNC turning centers are gaining in popularity as the parts they produce trend toward higher precision and micro-sized features. To be competitive, smart use of the machine’s full capabilities is a big advantage. Achieving “lights out” production and minimizing machine cycle times are key tactical objectives. Join Matt Saccomanno, co-founder and CEO of Masa Tool, as he explains advanced work holding techniques that fundamentally change the scope of what is possible on a Swiss-type machine (also known as “sliding head” or guide bushing machine). Balancing the main and sub-spindle cycle times, achieving reliable untended , lights out production, and reducing scrap and down time will be the focus of this informative and interactive presentation. Much of this material is also applicable to other types of machining centers, especially when making small parts. Bring your real-world “problem parts” to the session for a strategy discussion with Mr. Saccomanno. This session is beneficial for machinists, CNC programmers, manufacturing engineers, tool crib personnel, and hands-on managers. About the Speaker

About Masa Tool Inc.With deep roots in the Swiss-type screw machine industry, Masa Tool Inc. was founded in Oceanside California with the mission of bringing the Microconic System to the world. This revolutionary workholding system consists of the Microconic “cartridge” and “collet”. It was invented to solve the problems created by traditional long nose collets commonly used in the sub-spindle of screw machines for over 100 years.

As screw machines evolved from mechanical cams in the late 1900’s to today’s CNC controls, the complexity of parts being made increased dramatically. Making these modern micro precision parts complete on the machine without additional secondary operations became critical to remain competitive. Using the machine’s sub-spindle to complete the part is a must. As the demands for precision and complexity increase, the traditional long-nose collet has many limitations that can frustrate the machinist trying to get the most out of the machine. We created the Microconic system to overcome these limitations of conventional collets. The result is superior rigidity, accuracy, over-grip capability, clamping force control, and long-run stability. We at Masa built our company from the ground up to ensure that everything in our catalog is available to ship within 2 days. Every size, every type. We currently offer any size from 0.2mm – 10mm diameter (.008” - .394”). Masa Tool’s Microconic push-type F201M10 cartridge pairs with its Microconic collets for concentricity within 5 microns (0.0002") in production use Masa Tool’s Microconic push-type F201M10 cartridge pairs with its Microconic collets for concentricity said to be within 5 microns (0.0002") in production use. The cartridge is a micro-workholding system for use in high-precision, small-diameter CNC turning applications. The cartridge is compatible with spindles that accept F20-201 collets.  Masa Tool's Microconic F201M10 cartridge on display at IMTS 2018. Masa Tool's Microconic F201M10 cartridge on display at IMTS 2018. The cartridge and accompanying collet are designed to vector the chucking force directly over the holding surface, reducing the chucking force while also increasing the holding power. This reduces chucking damage on the workpiece and reduces cycle times by 20 to 40 percent, the company says. The cartridge’s solid extended nose enables access for tooling and coolant with minimal overhang. Its core diameter is a single-piece construction that is designed to maintain 5 microns (0.002") concentricity at the extended nose tip. Used with the company’s Micrograd wrench, the cartridge features micrometer dial control of collet clamping pressure regardless of the machine’s hydraulic or pneumatic collet closing force. The cartridge is suited for small-diameter parts ranging from 0.22 mm (0.008") to 10 mm (0.3934") in diameter. "Micro-movement" of the workpiece is reduced, resulting in a longer tool life, better finishes, fewer chatter problems, and less damage to the workpiece. The cartridge eliminates secondary operations, saves time and enables operations to be done in the subspindle. Broaching, milling, saw cutting/slotting, turning, boring and drilling can be machined in the subspindle.

We have just released the NEW 2018-2019 Masa Tool Catalog! Our first batch of new catalogs is shipping directly to our IMTS booth in Chicago for release, but you can download your own copy right here!

OCEANSIDE, CA - Masa Tool has just released the newest product in the Microconic line of cartridges for swiss machine workholding. The NEW push type F37M10 Cartridge replaces the standard TF37 collet in your CNC spindle. This enables you to use our Microconic collets to achieve concentricity guaranteed to be within 5µm (0.0002") in production use. The F37M10 Cartridge is a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. Compatible with spindles that accept DIN 1536E, Meister Swiss 563, Schaublin F37 (76-740), Southwick & Meister TF37, KEB (MasWerks) MC37, Hardinge TF37 / 4619 collets. Masa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of moving part operations to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. This new cartridge will be demonstrated for the first time at IMTS 2018 in the West Building, Level 3 & Annex - Tooling & Workholding Systems - 432232

Matt Saccomanno, the Co-Founder of Masa Tool and inventor of the Microconic Workholding sytem will talking about process innovations in the metalcutting manufacturing industry during the International Manufacturing Technology Show, IMTS, in September at McCormick Place in Chicago, IL. Swiss-type CNC machines have gained in capability and demand as the machined components they produce are trending toward higher precision and micro-sized features. As the machines have become more sophisticated, the underlying basics of workholding remained unchanged until recently.

This presentation is an overview of new developments as well as traditional approaches with relevance to today’s highly capable sliding headstock “Swiss-type” CNC turning centers. The goal is to summarize best-practices for optimizing use of both main and sub-spindle to maximize productivity and overall equipment effectiveness. The material presented is useful for machinists, CNC programmers, tool crib personnel, manufacturing engineers, estimators, and hands-on managers. If you would like to reserve your spot in this technical presentation and discussion please click the below button. Marubeni Citizen introduced their famed L20 series with low-frequency vibration (LFV) cutting at IMTS 2016. The new LFV machine featured the Microconic workholding system in the subspindle. They utilized a F20M10 Microconic cartridge in their TF20 subspindle with one of our overgrip collets to demonstrate the performance of the new LFV. You can check out our segment starting at 8 minutes into the video! We want to extend a very big thank you to Marubeni Citizen for putting our system as a feature of their very latest in technology!

We where honored and privileged to be interviewed by IMTStv during the show in 2016! It enabled us to get the word out about our Microconic workholding solution that solves clamping problems that have never been solved before!

We discussed that many many people had just given up on trying to find a solution for balancing out production between the main spindle and the sub-spindle years and years ago. We where even more excited than most of the people that stopped by our booth to learn that we had indeed invented something that fixes the problem!

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed