Microconic Over-Grip Collets T-Type

The Microconic "W-type" over-grip collets work great for many parts that require over-grip in the sub spindle . They enable you to move operations from the main spindle to the sub-spindle. This balances the work being performed between the main and sub, which can dramatically reduce cycle time.

Why the T-type is different

When trying to hold parts like long bonescrews with wide pitch threads, or longer parts in general, there is a need for a longer grip land. Our "T-type" over-grip collet has a longer gripping surface than our original W-type. The T-type is designed for applications such as this.

Why the T-type is different

When trying to hold parts like long bonescrews with wide pitch threads, or longer parts in general, there is a need for a longer grip land. Our "T-type" over-grip collet has a longer gripping surface than our original W-type. The T-type is designed for applications such as this.

No other collet on the market can “overgrip” as much as the Microconic over-grip collet with the Masa Cartridge. The Microconic over-grip collets can open up to 3.5mm, 0.138" over the chucking diameter and run within 5 µm/.0002" TIR.

|

Typical uses for the T-type over-grip collets are generally for longer parts such as:

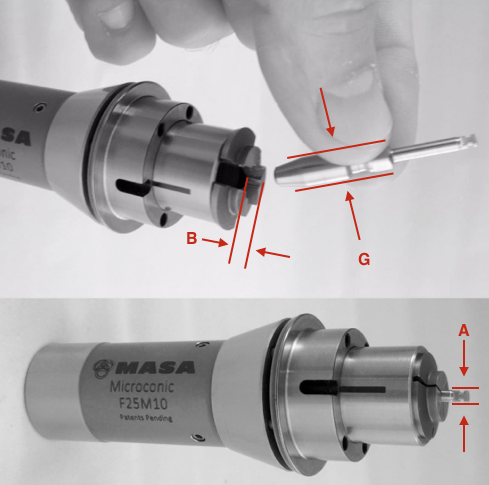

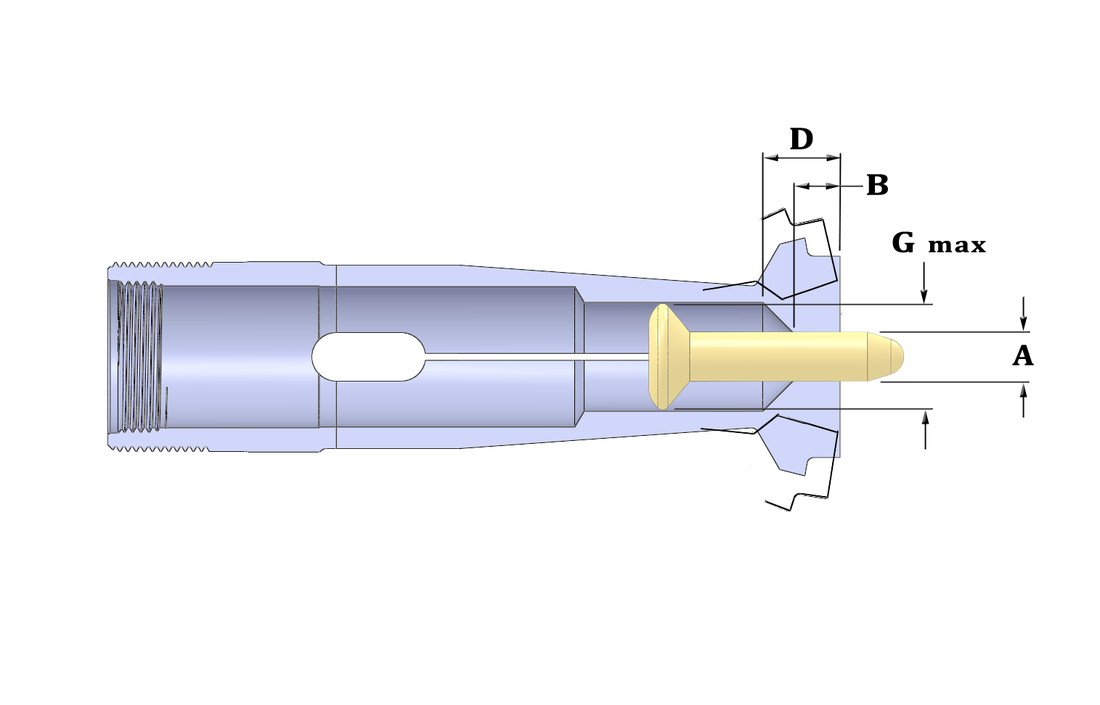

Over-grip collets, also referred to as over-the-shoulder collets, are used in a pick-off /sub-spindle when it is required to clear a shoulder and grip on a smaller diameter beyond the larger diameter. The surgical drill blank pictured at the left is a good example of this kind part.

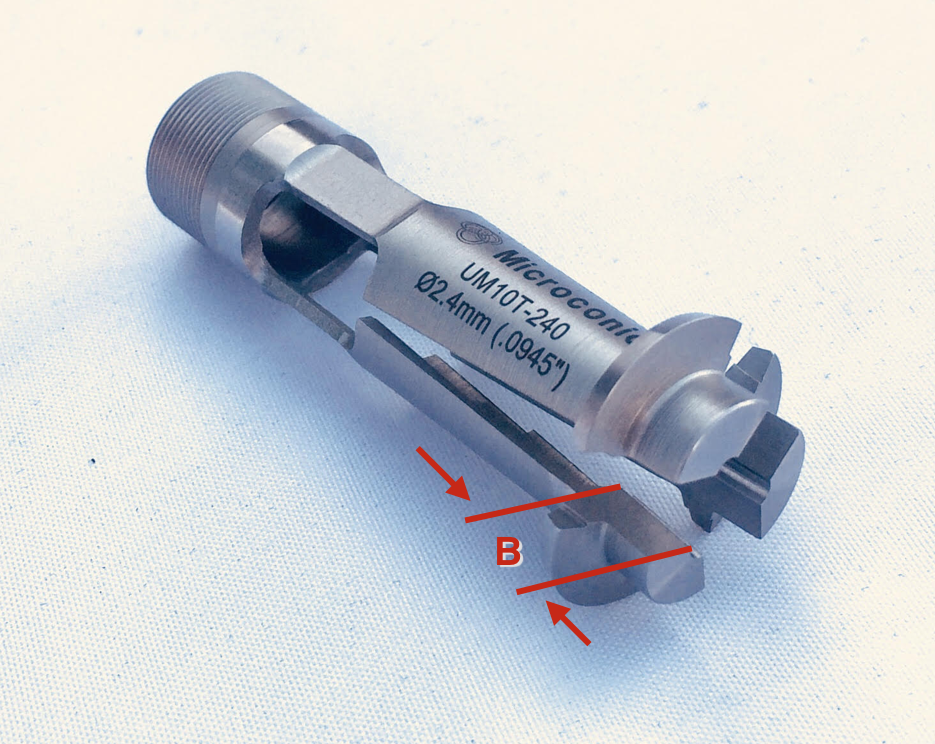

Extra spread is required to open the collet wide enough to go over the larger diameter. The grip diameter (A), the width of the grip land (B) and the largest part diameter to reach over (G) are required information to choose the off-the-shelf over-grip collet for your specific part.

Microconic over-grip collets are a great way to expand your machine's capability, eliminate secondary operations and reduce cycle time.

|

T-type Over-Grip Collet Advantages

- Standard gripping land length is 2x - 3x diameter. compared to the 1x diameter with W-type over-grip collets.

- Available from Ø1.55 - 7.2mm (Ø0.061" -0.283").

- Opens up to 3.5mm (0.138") diameter larger than the clamping diameter. Some restrictions apply to larger sizes approaching the 6.0mm (0.236") max diameter. (vs. 4mm larger with W-type)

- Grips with the same industry-best rigidity and accuracy as our regular collets.

- Compatible with all Microconic M10 cartridges: F20M10, F25M10 & 5CM10.

- Fatigue tested design to over 250,000 full-load cycles.

- All sizes available to ship in 2 days.

- Reduce part cycle time by moving operations to the sub spindle that you might currently be performing in the main spindle.

How to use the Microguide Sleeve

Due to the extreme opening capability of our overgrip collets , workpiece ejection must be very reliable to prevent a part from becoming stuck in the slots of the collet. Therefore we have developed the Microguide™ ejection guide sleeve to prevent parts from falling inside the collet instead of ejecting into the part catcher.

|

The Microguide™ sleeve can be bored, drilled or machined to match the part profile and support the part and guide it for reliable ejection into the part catcher.

You will need to machine the Microguide™ to fit your particular part setup. We suggest using programmed cycle stops while validating the production setup to make sure part ejection is reliable. |

|

The Microconic™ over-grip collet is extremely rigid and precise. If it closes onto a part wrapped with chips the collet may be over-stressed and break. It is critical that the workpiece be free of wrapped chips. High pressure coolant is recommended to blast away chips.

There are many other techniques that can be applied to keep the part clear of chips, such as chipbreaker inserts, speed/feed optimization, chipbreaker G-code cycles and cutter path retracing, amongst others. It bears repeating that we suggest using programmed cycle stops while validating the production setup so the operator can confirm the part is clear. Once chip control is proven reliable that won't be necessary. |

Now you can over-grip and do REAL MACHINING in the sub-spindle!