|

Set ups are quicker and more repeatable with Microconic™. You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

How to use the Micrograd™ Face Dial Wrench

For a complete set of instructions please see our installation procedures for more details on how to set up and replicate your clamping pressure on every machine in your shop.

1 Comment

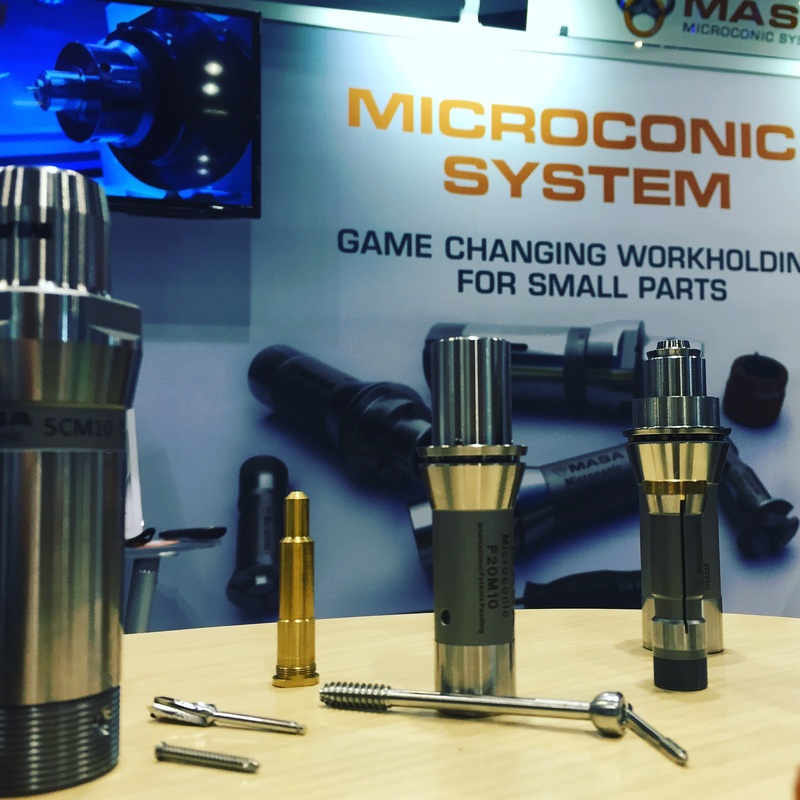

Masa Tool is introducing its Microconic workholding system for use in subspindle Swiss-type machine operations, enabling the operator to switch operations from the main to the subspindle so that usage is balanced. Masa Tool is introducing its Microconic workholding system for use in subspindle Swiss-type machine operations, enabling the operator to switch operations from the main to the subspindle so that usage is balanced. This capability is said to reduce cycle time in ways that are not possible with conventional collets. The Microconic system consists of two primary components: a cartridge that fits in the machine’s standard TF20, TF25 or 5C collet closer, and the collet itself, which fits into the cartridge. Each cartridge model has a solid extended nose and can accept both regular and over-grip collets. The over-grip collets open up to 0.157" (4 mm) larger than the clamping diameter. The Microconic cartridge’s extended nose design directs all of the chucking pressure directly over the workpiece for concentricity and rigidity. Total indicated runout (TIR) for the Microconic system is guaranteed at 0.0002" (5 µm) at the workpiece, absent any runout introduced by the machine structure or other elements of the setup. The system capacity ranges from 0.008" to 0.394" (0.2 to 10 mm) in diameter, with all sizes available from stock.

The Microconic system will be able to do things that are impossible |

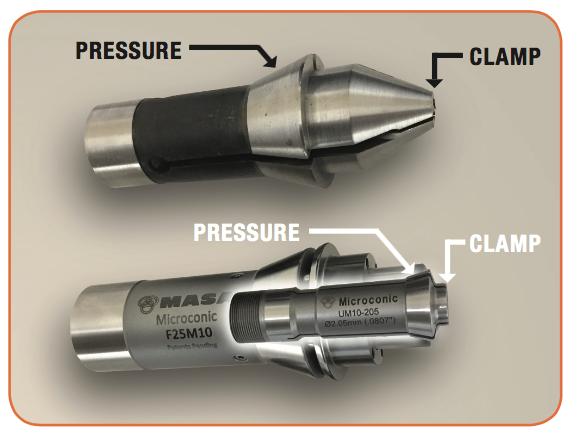

| Our regular MicroconicTM collets help reduce cycle time by allowing a rm grip on the workpiece without causing damage, and yet holding it much more rigidly than any other collet on the market. You’ll be able to do heavy machining operations in the sub spindle, such as blind hole broaching, that would not have even considered in the past. Now you can switch ops from main to sub! Set ups are quicker and more repeatable with Microconic. You can document the micrometer-adjust collet closure in your set up plan using our Micrograd Face Dial Wrench and it’s going to repeat to the same clamping pressure each and every time, regardless of operator skill and without relying on “feel”. You can calibrate your spindle accuracy with the MicroconicTM cartridge by using it as a precision cylinder gauge. When that is good, EVERY Microconic collet will run within .0002” TIR: There’s no ddling and swapping collet after collet looking for a “good” one. Set ups go smoothly and predictably. | The Microconic collets fit into our cartridge to hold the workpiece with great precision and rigidity. Unlike traditional extended nose collets our unique design and closing action is inherently more accurate and consistent. The clamping force is directly over the workpiece at the end of the collet. The origin of the word “Microconic”, alludes to the precise way in which the collet closing taper is formed to cancel the effects of heat treat warp and grind tolerances. As a result, it provides industry- best concentricity every time. |

Download or View the 2017 Masa Tool Microconic Catalog:

We discussed that many many people had just given up on trying to find a solution for balancing out production between the main spindle and the sub-spindle years and years ago. We where even more excited than most of the people that stopped by our booth to learn that we had indeed invented something that fixes the problem!

|

A big thank you to the folks at AMT and IMTStv who interviewed us at the show for the big screen!!

"If you manufacture small parts, you have to see this microconic system, it's no ordinary collet! Check out what we found in the west hall at Microconic by Masa Tool's booth W-2232!" Watch more videos at IMTS.com/IMTSTV |

|

Masa Tool has developed the Microconic™ system specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck.

The system consists of two major components: The Microconic™ cartridge, which fits into your CNC machine spindle replacing the standard 5C, TF20 or TF25 collets, and the Microconic™ collet, which fits in the Microconic™ cartridge.

The Microconic™ system has unsurpassed concentricity: Our manufacturing tolerance is 3µm (.0001") and we guarantee our cartridges to be within 5µm (0.0002") in production use in your machine.

The Microconic™ system works with either draw-type or push-type standard collet systems that are in any machine.

The Over-grip collet capabilities of Masa Microconic™ System, introduces a whole new world of time saving opportunities awaiting. Our Overgrip Collets open up to 4mm (0.157") diameter larger than the clamping diameter.

|

On Sunday, we where interviewed on IMTStv and had some time to talk to the great folks from AMT about our Microconic system technology and where heard from people that we where on the big screen throughout the show.

We're keeping an eye on YouTube to see it and we'll be sure to share it here when we find it. :-) We really can't express enough thanks to the folks over at Citizen for using our Microconic system on their new L20 machine with low frequency vibration technology that was on display in their booth. The application engineers sent quite a few people over to our booth once they saw it in the machine! |

Be sure to keep an eye our for some articles in some pretty big name magazines in the next few months. We're now on the look out for some application stories for them based upon the success you've had with our product. If you have a story to tell us be sure to leave it in the comments below or contact us so we can get all the details!

|

Harry Moser form the Reshoring Initiative visited us!

|

Some pictures from our IMTStv interview. It was a busy week meeting lots of new customers!

|

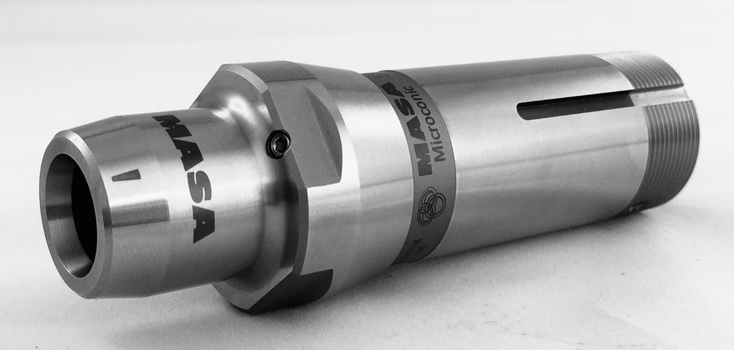

The Microconic™ work holding system is a mechanically actuated micro-workholding system for use in high precision, small diameter CNC turning applications.

The system consists of two major components: The Microconic™ cartridge, replaces the standard TF20 collets and fits into your CNC machine with no modifications to the spindle required. The second component to the system is the Microconic™ collets which have capacities of 0,22mm - 10,00mm ( 0.0086" - 0.3949") and -Over-Grip collets which can open up to 4mm over the chucking diameter and run within 5 µm/.0002" TIR

It's the first and only workholding system for the micro-machining industry.

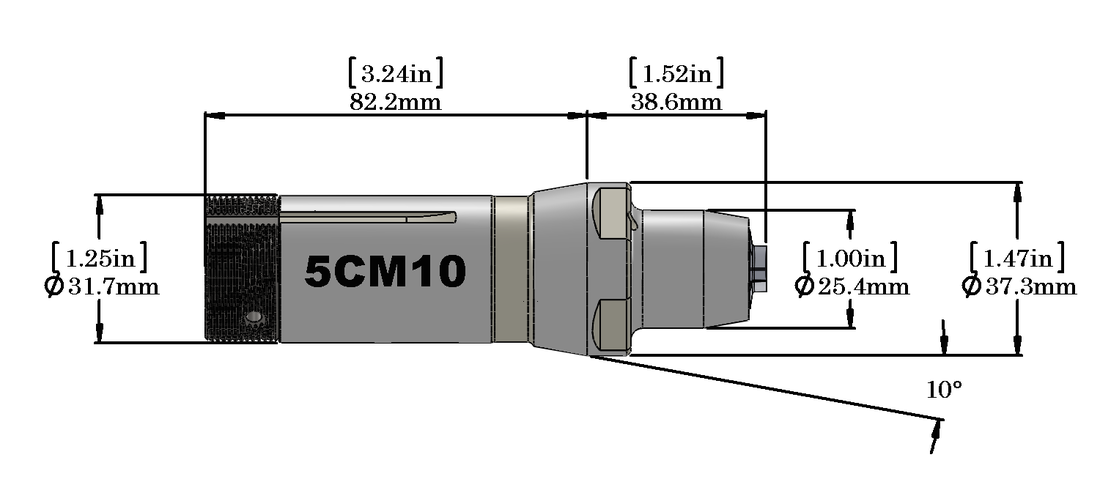

| 5C collets are some of the most widely used and versatile clamping methods used in metalcutting lathes and mills today but have never been able to provide the accuracy and rigidity often needed for small diameter parts. Until now... Development of the the 5C cartridge dates back to the late 1990's but this newly introduced version is manufactured using our unique "Microconic" production methods that provide more accuracy and rigidity than was ever possible with any other "off-the-shelf" rotating clamping system. The “Microconic System” is a miniaturized collet system that consists of two major components: the Microconic “cartridge” that fits directly into 5C spindles and the Microconic collet that is a “right size” style collet. The major features of the new 5C cartridge include:

| Applications:

|

Masa Tool is an international rotary workholding manufacturer of a unique clamping system called Microconic. Based in Oceanside, California, it's experienced staff is dedicated to providing customers the most innovative rotary workholding technology possible for small diameter, high tolerance part machining. In 2015, Masa Tool moved into it's new manufacturing facility in Oceanside, CA, located midway between Long Beach and San Diego to serve its growing customer base with increased production capacity, sales and service, plus an extensive inventory of products. Masa Tool serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of CNC machine tool OEM’s worldwide.

This article originally appeared in Modern Machine Shop |

An adapter is available, however, that renders a common 5C machine tool capable of handling very small diameter parts. The new small parts adapter, manufactured by Masa Machine Tool Accessories, Oceanside, California, fits in any machine's 5C collet closer, just like a standard 5C collet, without any modifications or special mounting procedures.

| With the adapter, any machine with a 5C collet closer can chuck workpieces in the range of 0.010 to 0.375-inch diameter (0.25 to 10 mm). Yes, I truly mean that a common CNC turret lathe with one-inch shank tooling and a brutally powerful hydraulic 5C collet closer can easily chuck fragile 0.010-inch diameter workpieces effectively and repeatably, without damage. Of course, I don't recommend using a machine like that to make a part that small. However, this shows the level of control that the adapter provides. |

Author

Here you will find the latest press releases, news coverage and technical information about our Microconic™ system

Archives

February 2023

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

January 2022

October 2021

May 2021

July 2020

March 2020

February 2020

December 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

June 2017

May 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

March 2016

February 2016

January 2016

December 2015

November 2015

October 2015

September 2015

August 2015

July 2015

May 2015

April 2015

August 2014

May 2014

March 2014

July 1999

Categories

All

5C Cartridge

5C Collet

Advanced Manufacturing

Advertisement

Agent Profile

AMTS

APT Machine Tools

Avinger

Bell Mouthing

Bone Screws

Case Study

Catalog

CEO CFO

Chip Wrapping

Cincom

Cincom L12

Cincom L20

Cincom M16

Cincom M32

CNC West

Collet

Concentricity

Dental Implants

Dragan Marjanovic

Dunner SA

Eastec

Ejection Guide Sleeve

Emergency Collet

F13M5

F15M5

F16M5

F201M10

F20M10

F37M10

Floyd Automatic

Ganesh

High Tech Industrial

IMTS

ISwiss

Jones Marketing

Lane 4

Machinery Trade International

Magazine Article

Mann Sales

Marubeni Citizen

Material: 6Al4V

MAV Innovations

Metal Cutting Corp

Microconic

Micrograd Wrench

Microguide Sleeve

Micromachining

Micro-Matics

Modern Machine Shop

Morris South

NETC

Next Generation Tooling

Oceanside Facility

Oktoberfest

Open House

Overgrip Collet

Part: Counterbore Drills

Part: Dental Drills

Part: Dental Impant

Part: Medical Device

Part: Surgical Drills

Part: Surgical Taps

PMTS

Press Release

Production Machining

Productivity Inc.

Ram Sales & Marketing

Schlenker

SIAMS

South Tec

South- Tec

Star CNC

Star SR20

STEM

Tech Tip

TF15

TF16

TF20

TF25

TF37

Todays Medical Developments

Tool Marketing Service

Trade Show

Trade Shows

Tsugami

UM10

UM10T

UM10W

UM5

UM5T

UM5V

UM5W

Videos

Workpiece Deflection

RSS Feed

RSS Feed