|

Now available from Floyd Automatic Tooling in the UK is the expanded range of Masa Microconic over-grip spindle collets. The precise and stable clamping of small workpieces in the sub-spindle of sliding head machines has long been an issue for turned parts manufacturers. Masa says it has revolutionised this problem for manufacturers to deliver improved precision workholding.

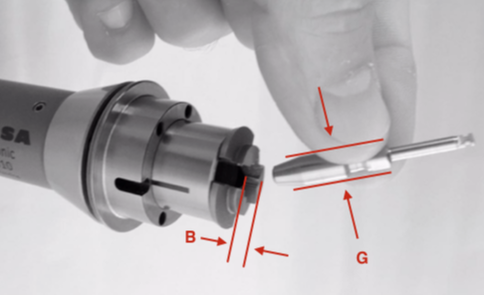

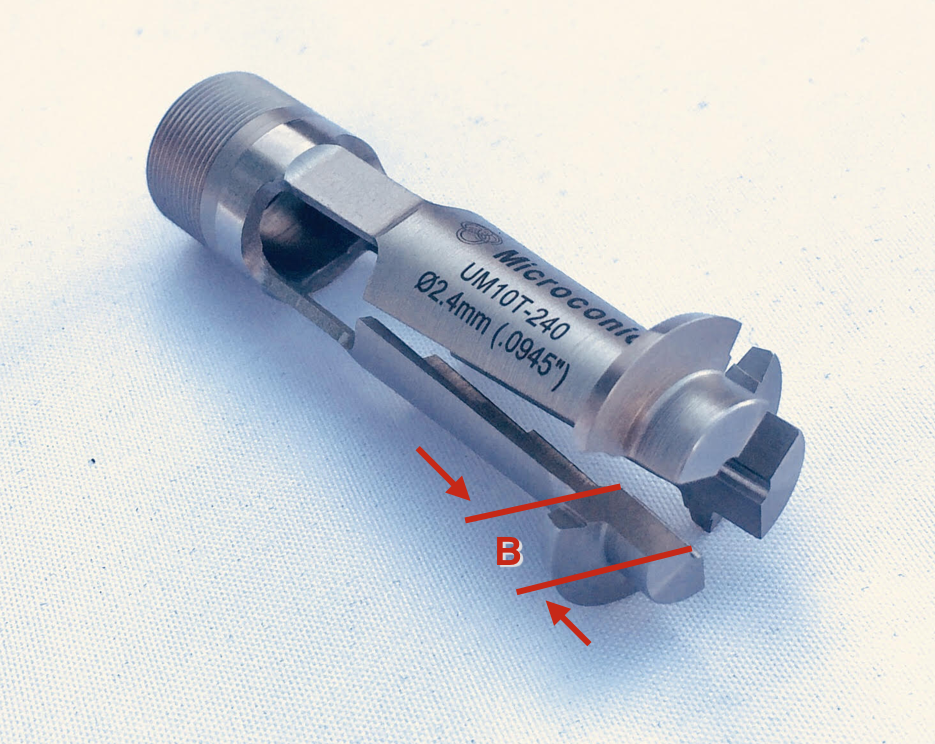

Until now, this popular solution has been specified primarily on 20 and 32mm capacity sliding head machines. However, the demand for the system has now seen Masa expand the series to cater for manufacturers working on 10 and 12mm diameter capacity machines. To understand the Microconic system, manufacturers must first consider that only three things are in physical contact with the workpiece, the cutting tool, coolant/cutting fluid and the workholding. The Microconic over-grip collet system ultimately allows manufacturers to rethink what is possible. This innovative workholding system consists of a cartridge and precision collet. The over-grip collet fits inside a cartridge and is accurately adjusted before it is fitted directly into the existing collet sleeve with no machine adaptations required. The patented over-grip collets can open up to 4mm larger than the clamping diameter and also incorporate an ejection guide sleeve blank. This helps the end user to solve the difficulty of ejecting parts from the collets after machining and allows manufacturers to reach behind flanges, parts with heads or any other enlarged feature. Ideal for processing parts with stepped features such as connectors, screws or other common components, the over-clamp system can clamp over the protruding features and securely hold on the main body of components. The collets are available with clamping diameters from 0.2mm to 10mm, meaning the most fragile of parts can be clamped safely and precisely. With concentricity between 3 to 5µm, the Masa Microconic system is perfect for high-precision machining. Previously, the system was available with F20, F25 and F37 style collets and this has been expanded over time. Now, it is offered with F15 and F16 to deliver high-precision clamping for challenging components. The F15 M5 cartridge works in synergy with most 10 to 16mm capacity machine tools from manufacturers like Star, Citizen, Tsugami and Maier whilst the F16 M5 variant is perfect for other machine tool brands such as Citizen, Hanwha, Tornos and Nexturn to name a few. Commenting upon the expanded range, Floyd Automatic Tooling managing director, Richard Floyd says: “The expansion to the line has been sought after for a long time. This is a credit to the success of the Masa Microconic collets for 20mm and 32mm diameter capacity machines. “Small-diameter sub-spindle clamping and over-gripping applications have historically been a bane for users of sliding head turning centres. This radical, but elegant solution brings repeatability and precision to small part turning, solving the challenge of clamping difficult parts.” Floyd Automatic Tooling www.floydautomatic.co.uk

0 Comments

OCEANSIDE, CA. - At IMTS 2022 we where visited by the great folks at GIE Media, Inc. who publish Today's Medical Developments, Aerospace Manufacturing and Design and Today’s eMobility. They asked Matt Saccomanno, the inventor of the Microconic system to give them an on-camera overview of our products and how they work. As you probably already know, Masa’s Microconic Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface in your Swiss type CNC screw machine. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of shifting part operations from the main to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. At IMTS 2022, we expanded our Microconic line of swiss type CNC machine workholding. The new push type F15M5 and F16M5 cartridges replace the standard TF15 and TF16 collets in your CNC spindle. This enables you to use the newly introduced Microconic UM5 collet series with the Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. The off-the-shelf Microconic system concentricity of the cartridge and collet system combination is guaranteed to be within 5µm (0.0002") in production use. Both the F15M5 and F16M5 cartridges are a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F15M5 cartridge is compatible with spindles that accept Schaublin F15 76-580, E120, Southwick & Meister TF15 and Hardinge TF15 / 4607 collets, while the F16M5 cartridge is compatible with spindles that accept Schaublin F16 76-1076, E1212, Southwick & Meister TF16 and Hardinge TF16 / 4609 collets. Along with the new smaller cartridges comes a comprehensive series of UM5 collets that are ideally suited for small diameter part sizes ranging from 0.2mm/.008" to 5.5mm/.217" in diameter. These are available in regular type UM5 collets as well as all three types of Microconic's T, V and W type Over-Grip collets. Masa Tool offers the most unique variety of over-grip collets in the industry. And yes, if you listened closely to the video, you heard correctly, Matt spilled the beans on the new product that we'll be releasing next: The F13M5 Cartridge. And after that, we're going to heed that advise of "go big or go home. Yea, that was a spoiler alert.  The things that seems to excite Swiss machinists the most is our Micrograd™ wrench. The Micrograd Dial Wrenches provides a method of precisely setting clamping pressure on both the regular Microconic collets and on all series of Microconic over-grip collets. It can be adjusted in an infinite number of increments between the metric graduations of 0,02mm and inch/imperial graduations of .001" With the Micrograd Dial you can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel". Masa Tool's Microconic cartridge is made of exotic high-chromium tool steel, triple tempered and cryogenically treated to provide stable construction. All functional seating surfaces are ground with extreme precision on a one-piece, ultra-rigid body structure.

“The cartridge can be used as a calibration gage to verify the machine spindle accuracy,” Co-owner Chip Prescott notes. Microconic collets are finished to exacting standards with a five-step grinding process that removes the effect of heat-treat warpage. Also, the proprietary Microconic form of the closure surfaces is inherently more accurate than traditional collets, providing for a greater full-accuracy working range. Cartridges are available to fit in push-type dead-length collet closers and also draw-type closers: F20M10 (for TF20 collet replacement), F25M10 (for TF25 collet replacement), and 5CM10 (for 5C collet replacement). All of these cartridges use the same Microconic UM10 collets, with more cartridge sizes in development to be released soon. High precision long nose collet system for sliding-head Swiss-type CNC lathe/turning centers. Opens 4mm larger than clamping diameter! Super accurate, super rigid. PMTS 2019: Masa Tool’s F37M10 cartridge is said to replace the standard TF37 collet in a users CNC spindle. #PMTS Masa Tool’s F37M10 cartridge is said to replace the standard TF37 collet in a users CNC spindle. This enables the use of the company’s Microconic collets to achieve concentricity within 5 microns (0.0002"), according to the company. The cartridge is a micro-workholding system for use in high precision, small diameter CNC turning applications. This cartridge is compatible with spindles that accept DIN 1536E, Meister Swiss 563, Schaublin F37 (76-740), Southwick and Meister TF37, KEB (MasWerks) MC37 and Hardinge TF37 / 4619 collets. The company’s cartridge and collet assembly is designed to vector the chucking force directly over the holding surface. This means the chucking force is reduced while at the same time the holding power is increased. This is said to open up the possibility of moving part operations to the sub-spindle and reducing cycle time. Also, the cycle time is commonly reduced by 20-40 percent.

We have just released the NEW 2018-2019 Masa Tool Catalog! Our first batch of new catalogs is shipping directly to our IMTS booth in Chicago for release, but you can download your own copy right here!

OCEANSIDE, CA - Masa Tool has just released the newest product in the Microconic line of cartridges for swiss machine workholding. The NEW push type F37M10 Cartridge replaces the standard TF37 collet in your CNC spindle. This enables you to use our Microconic collets to achieve concentricity guaranteed to be within 5µm (0.0002") in production use. The F37M10 Cartridge is a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. Compatible with spindles that accept DIN 1536E, Meister Swiss 563, Schaublin F37 (76-740), Southwick & Meister TF37, KEB (MasWerks) MC37, Hardinge TF37 / 4619 collets. Masa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of moving part operations to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. This new cartridge will be demonstrated for the first time at IMTS 2018 in the West Building, Level 3 & Annex - Tooling & Workholding Systems - 432232

OCEANSIDE, CA. Masa Tool has expanded their line of Microconic over-grip collets to include a new style called a "T-type." The T-type over-grip collet has a longer gripping surface than the original W-type. We designed it specifically for longer parts such as bone screws with wide pitch threads.

But, in some cases, with longer parts, the land width "B" needs to be longer to support the workpiece properly. Masa's new T-type collet provides the solution for longer workpiecesTypically with over-gripping applications, a shorter land length/clamping pad length/grip length is desired because of limited space available to hold the workpiece behind the enlarged head or flange that it is reaching over. That is what our original W-type collet was optimized for. However, with longer parts, with more surface area for clamping and gripping room, a longer land length is often preferred to provide more stability to support the longer length workpiece.

Microconic T-Type Over-grip Collet features

If you've tried other companies overgrip collets with poor results, Microconic over-grip collets will allow you to do things you might have thought impossible!

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed