|

This Swiss shop discovered workholding collets that satisfy the needs of its very small, delicate and complex medical parts production on the subspindle, making once impossible processes not only doable but more efficient and esthetically pleasing. Workholding, particularly for backworking operations, can be tricky when machining very small parts in a CNC Swiss-type lathe. Depending on their design, pickoff collets can produce a variety of problems, including poor concentricity and runout as well as poor control of clamping force, causing part damage. That is why when Dan Fifer, owner of Lane4 Precision (Santa Rosa, California) discovered collets that worked well for his applications, he became a dedicated customer of the manufacturer and trusted the company’s workholding system with his most delicate and complex parts.

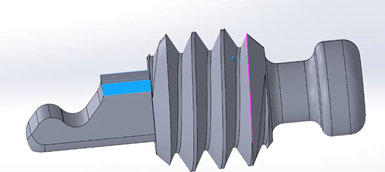

In addition, Fifer says the Microconic collets enable fine adjustment of the collet tension on complex parts. These collets enabled the shop to machine parts it was formerly unable to create with other collets, as well as frequently and effectively perform backworking operations. From Designer to Job Shop in 1 MonthAlthough he quickly learned about the workholding necessary to machine his customers’ parts most efficiently, Fifer did not initially have experience with CNC Swiss-type machining. In fact, when he opened Lane4 Precision in 2017, he had never stood in front of a CNC machine control panel before, let alone a CNC Swiss-type lathe. His background was rooted in design/product development for the medical device industry. After working for several startups for over 20 years, he says he was anxious to be the one to create the parts instead of designing them. So, he took his passion for innovation and rented a warehouse space where he decided to do all the machining processes in-house. He says someone told him he needed a screw machine to do the work he wanted to accomplish. The timing was good for him to attend IMTS 2016 to shop for a machine tool, and that’s where he met Spinetti Machinery, a distributor that sells Marubeni Citizen-Cincom Swiss-types. He was impressed with the machines’ predictability, and he was confident that the Spinetti team would support him and help him learn how to operate his first Swiss-type, a Citizen L20. Once this sophisticated machine was set up, an industry colleague asked Fifer if he thought he could make a part that had already been designed. His colleague said no one could build it for him, not because it was not able to be done, but because the colleague did not want to wait 12 weeks to have the order complete. “I said, well, I have nothing else to do, so I will figure it out,” Fifer says. “So, basically, within a month I was absolutely swamped from a team of about six engineers feeding me more parts that I was able to do.” With Spinetti’s assistance, he has since selected four more of the Citizen Swiss lathes with different work envelopes and capabilities such as a live B-axis, automatic toolchanger and the machine tool builder’s low frequency vibration technology that helps create small, easily evacuated chips. The distributor was also responsible for introducing Fifer to the Microconic workholding system. A very small part on an L12 was the first job he ran with the workholding system. Extended Nose Without ExtensionThree-quarters of the machining done at Lane4 Precision, which is mostly a prototype shop, is for the medical industry, and the rest are premium parts for the semiconductor, defense, aerospace and consumer products industries, according to Fifer. Parts range in size from fitting within a work envelope of a grain of rice (length or diameter of a half a millimeter or so) to long slender parts over two feet long.  Quickly moving from a designer to a job shop, Fifer never has put his eye for design on the back burner. He considers his niche to be that of helping his customers with design when appropriate. For instance, if he understands a more efficient way to machine something, he volunteers his expertise. “If I can see their design intent, I might say, ‘By the way, you can chamfer this edge, and it won’t cost you anything because I already have the tool’,” he explains. “They might have had two parts I was making that they were welding together.” Because some parts produced by the shop contain thin walls and have short pickoff lands, it was critical that the workholding system installed offer acceptable tool clearances and fine adjustability for subspindle backworking. The shop also needed compact and reliable over-grip collets for the most complex applications (more about that later). Fifer found his expectations met and then some after installing the Microconic workholding system. In fact, he was so pleased that he eventually added it to all five of his Swiss-types. Masa Tool, which only specializes in subspindle collet workholding, has designed the Microconic workholding system which consists of cartridges that are installed in a machine like a standard collet. The cartridge, which offers 0.0002-inch TIR, can be used as a gage to verify machine spindle accuracy. Also, the adjustment dial wrench offers precise and repeatable control of the clamping force, according to the company. Because the cartridge is built with an extended nose, extended nose collets are not necessary, making this system well-suited for Lane4 Precision considering most of its applications require an extended nose pickoff collet. Fifer explains that the Masa collet closure mechanism has been moved right up to the collet nose, improving rigidity relative to standard extended nose collets. All Masa collets fit into the machine’s cartridge or an adaptor sleeve from the company, making it easy for Fifer to change back and forth between collet styles on all his lathes.

He also points out that it usually takes only 5 minutes when changing over his lathes from machining “large” parts (which for Lane4 are those that are a half-inch diameter and larger) to machining smaller parts when using the Microconic collets. According to Masa, the changeover from a 16C to a 5C collet usually results in a tolerance accumulation and can sometimes take more than 15 minutes to change the collets. But, with the Masa system, once the cartridge is in place, collets can be quickly installed and clamping pressure set right at the spindle nose without tolerance stackup in less than a minute. Compact Over-GripFifer also appreciates Masa’s over-grip collets for parts that require those. He explains that, although these collets are compact, they offer a large opening and rigid holding. He says they outperform any alternatives he has tried in the past. “My cycle times, rigidity, tooling, everything is better,” he says. “They took away the fear of doing over-grip parts.”

However, the over-grip collets open up to 0.156-inch diameter larger than the holding diameter. According to Masa, these collets are still capable of 0.0002 inch of TIR. With such reliable gripping, Lane4 Precision has been able to expand its capabilities, even machining some intricate parts “backward,” providing higher quality parts, with fewer defects and a lower scrap rate, enabling operation without interruption.

Some SurprisesWhile learning the ins and outs of the Microconic system, Fifer says he realized how much confidence the workholding system’s design has given him to complete high-quality and miniature parts for his customers.For example, he appreciates that the collet nose is not chamfered. This design leaves more room for pickoff, he explains. “I used to have to face the collet before I could use it, so I could know what I was dealing with. But then it would alter the length of the collet.”

The advantages of excellent runout on the workholding system is another realization Fifer came to after he started putting it to use. It is possible to put very fine features on the backside of a part and maintain concentricity while also producing a “pretty” part. “If you have a 0.005-inch wall and you are trying to put 0.001-inch edge break on it, and you’ve got 0.001 inch of runout, the result is a really ugly part,” Fifer explains. “Using a Masa Microconic collet is like firm footing from the subspindle. At least you know you are starting in a good place for the most critical applications.”

0 Comments

To avoid crushing and ruining parts, Swiss precision manufacturer Micro-Matics turned to Masa Tool’s Microconic collet and cartridge system. Since 1973, Micro-Matics of Fridley, MN, has been manufacturing CNC Swiss precision screw machine products including many kinds of contacts & pins, ground shafts, hardened bushings, rivets, screws, spacers and other custom parts for the medical, dental, aerospace, commercial, defense, computer, telecommunications and automotive industries. According to Jason Wobig, Operations Manager, "Micro-Matics is primarily an aerospace and medical components, Swiss machining job shop. We make components that are thousandths of an inch up to an 1-1/4" in diameter. We started out with the old manual style, Cam driven Swiss machines and we're one of the largest Escomatic shops in the Midwest. And as the company's grown and evolved, we've turned into Swiss job shop, mostly Citizen machines like the M16, a L12, and a M32, as well as a few Star and Tsugami machines that give us a wide variety of capabilities."

|

| A while back Micro-Matics was running a small medical part, a catheter part, that they were struggling with. They had some custom collets made for pickoff and, according to Dave Thayer, Department Manager, "It was a constant struggle. This particular catheter part has very thin walls, it got crushed with a standard M16 collet system because you have very little accuracy in how much tension you're putting on your collet. If you put too much force on it, my parts started turning to collapse into triangles. If you don't have enough tension on it, the part pushes back into the pickoff and you get varying part lengths and varying chamfer diameters. The parts would be out round and they wouldn't be on-center." Wobig had heard about Masa Tool's Microconic™ sytems through Todd Pakiz, President of High Tech Representation Inc., New Prague, Minnesota. "Todd had told me about this system a couple years back. And we had been struggling with these parts. So I reached out to Todd and see if he's still selling that system." |

| Wobig continues, "I wanted to try this system for the catheter part which is a small thin-walled part approximately 0.040" in diameter and another 0.040" in length and with a wall thickness of 0.010". So I wanted something that wasn't crushing the part. It was really hard to adjust the machines pickoff spindle itself to any degree of accuracy without crushing a part." What Wobig found with the Masa Microconic system was that they could set up the clamping with a gage pin and set the clamping tension with the Micrograd™ Dial Wrench which has little indicators to set an actual tension. |

Cartridge and collet solution

The Microconic system consists of a cartridge and collet, with the cartridge fitting in the machine just like a standard legacy collet. The cartridge is a self-contained precision mechanism using the machine’s standard collet closing function, which means that the Microconic system can be used on any machine utilizing 5C, TF20, TF25 or TF37 collets.

According to Saccomanno "Since a collet system for any given machine must be made large enough to fit the maximum workpiece diameter capacity of the machine, the result is the standard collet mechanism is designed to handle the largest workpieces, which means it is excessively forceful and bulky when used for the smaller workpieces. Smaller parts get sacrificed, because they typically require a higher degree of accuracy and the workholding is more critical."

The Microconic system consists of the cartridge, which fits into your machine like a standard collet, and the Microconic collets which fit into Masa's unique cartridge. Every Microconic cartridge comes standard with extended nose for unsurpassed rigidity because of it's single piece construction.

"In fact, the cartridge is so accurate that it can be used as a gauge to verify machine spindle accuracy," said Pakiz.

Thayer explained how the Microconic system has worked for Micro-Matics "With the Masa system we're able to dial in a nice specific tension to hold that catheter part without crushing it or deforming it at all and having it on center. In a nutshell, we get better quality parts consistently with tighter tolerances. It's lead to a really significant improvement, it's increased throughput, so we have more parts at the end of the day."

"As a result of the implementation, the scrap rate on this part dropped dramatically once we added the new Masa system by at least 30%." added Wobig.

According to Masa Tool, the Microconic cartridge concentricity is guaranteed to be within 5µm (.0002") runnout and the collets are hardened and precision ground to the highest quality standards. The regular, UM10, 10mm collets, that Micro-Matics is using in their F20M10 Cartidge are available from Ø0.2mm (.008") to 10mm (.394"). In additon to the TF 20 spindles, the same collets can be used in TF25, TF37 and 5C sub spindles.

Applying technology to other applications

Micro-Matics has been running one of the collets for a couple of months straight now on a distal coupler.

Thayer explains, "The distal coupler part has a unique shape. It's not perfectly round. It has some small flats milled on either side of the part. It's like a cylindrical pill, like a capsule except with two sides of the long length milled in so there's flats on it. The part is 0.080" in length 0.040" in a cylindrical diameter. We then mill the cylindrical diameter 180 degrees from each other to a thickness of 0.030", so you're taking 0.10" off then drilling and centering two holes on each end of that through the flats."

"Our customer is extremely concerned about any collet indication marks or chip marks on the outside of that cylindrical diameter. The previous collets we were using were custom made collets that actually had the profile of the part basically machined into it" says Wobig.

| Thayer picks it up, "It was a straight cylinder round collet it but it was split in half so it was like two halves of a collet so we were trying to keep the flats in the spaces and then the round cylinder on the collet part that's round. The holding portion it would move and we didn't have them pinned at all. And then we had the same issue as on the catheter part: If you squeeze it too tight you're starting to push the diameter into the flat so it would deform the OD into the flat and make deformed flats. If you squeezed it too hard, it would make the flat bump up. If it didn't sit perfectly right in the custom collet you'd have the split marks of the collet that start interfering with the transition between the flat to the diameter and it would make lines on the diameter." | |

Remedying the issues

Thayer continued "The extended nose pieces on the Microconic cartridge helps on the catheter tips because you can get closer up to where I actually have a supporting back end. Because if I'm too far away from that supporting back and you have more of a tendency to crush the front of that part. The Microconic gives me a better tension on the part. On the distal coupler, we have to use a boring bar, or a facing tool to create the back face, which is round. We'd have a lot of trouble trying to hold without nibs or anything on there. And this holds it so that the part stays a little more square, and we're able to turn it better."

When dealing with very small parts and setting with small gage pins, accidents do sometimes happen. "The only problem I've had with it was when somebody was trying to set the collet tension with a pin. They put the pin into the slot and not the hole and wrecked the collet. Because the pin was able to fit inside the slot so when they started tightening it up, and the pins started deforming the collet was wrecked because it wasn't in the hole in the center." said Thayer.

Masa has indicated that they will release a new TF 15 and TF16 Cartridge with an entire series of smaller 5mm capacity collets at IMTS 2022.

Specificationz

Microconic over-grip collets have unmatched rigidity and concentricity compared to other manufacturers. The same collets can be used in TF20, TF25, and 5C sub spindles. Microconic collets permit interchangeability between machines, and the collets fit in any Microconic cartridge, no matter which collet system is in the machine.

New release

Marubeni Citizen-Cincom is the exclusive New England distributor for Citizen Cincom Swiss style lathes and Miyano Multi Axis turning centers as well as ne of our premier distributors of the Micorconic Workholding system

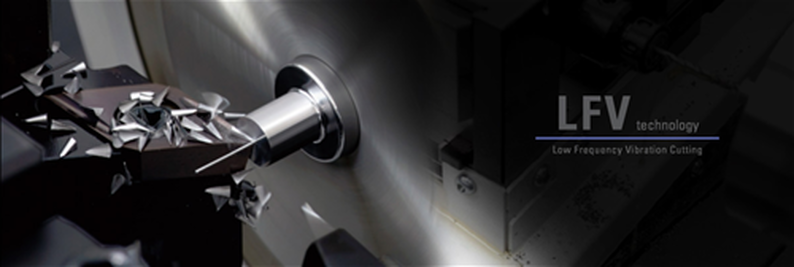

About the CINCOM L20 Low Frequency Vibration (LFV)

The popular Citizen CINCOM L20 series sliding headstock lathes are now available with Low Frequency Vibration (LFV).

This widely applicable cutting technology – able to handle a broad range of machining shapes and materials – is ideal for cutting difficult-to-cut materials. The state-of-the-art LFV suppresses various risks associated with these materials, such as entanglement of chips and built-up edges.

Depending on the material being cut, a variety of problems can be caused by chips getting entangled with each other, including increased cutting resistance, scarring, changes in the texture of the machined surface, tool nose damage, and built-up edges due to cutting heat. In LFV cutting, “air cutting” time prevents the machining temperature from rising, which both prolongs tool lives and gives relief from various problems caused by chips.

| This was the very first trade show for us in Dayton Ohio! It was held at the Dayton Convention Center and we where hosted by Ed and Mike from Tool Marketing Service's in their booth #425 that was just across the aisle from the Star CNC Booth. It was a great time to showcase our Microconic Workholding system for subspindels in swiss machining centers. We had to opportunity to talk to several application engineers Citizen, Star, Tsugami and Genesh and talk about several upcoming applications for bones screws being manufactured in the area. |

You can check out our segment starting at 8 minutes into the video! We want to extend a very big thank you to Marubeni Citizen for putting our system as a feature of their very latest in technology!

They where kind enough to share their test results with us.

Author

Here you will find the latest press releases, news coverage and technical information about our Microconic™ system

Archives

February 2023

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

January 2022

October 2021

May 2021

July 2020

March 2020

February 2020

December 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

June 2017

May 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

March 2016

February 2016

January 2016

December 2015

November 2015

October 2015

September 2015

August 2015

July 2015

May 2015

April 2015

August 2014

May 2014

March 2014

July 1999

Categories

All

5C Cartridge

5C Collet

Advanced Manufacturing

Advertisement

Agent Profile

AMTS

APT Machine Tools

Avinger

Bell Mouthing

Bone Screws

Case Study

Catalog

CEO CFO

Chip Wrapping

Cincom

Cincom L12

Cincom L20

Cincom M16

Cincom M32

CNC West

Collet

Concentricity

Dental Implants

Dragan Marjanovic

Dunner SA

Eastec

Ejection Guide Sleeve

Emergency Collet

F13M5

F15M5

F16M5

F201M10

F20M10

F37M10

Floyd Automatic

Ganesh

High Tech Industrial

IMTS

ISwiss

Jones Marketing

Lane 4

Machinery Trade International

Magazine Article

Mann Sales

Marubeni Citizen

Material: 6Al4V

MAV Innovations

Metal Cutting Corp

Microconic

Micrograd Wrench

Microguide Sleeve

Micromachining

Micro-Matics

Modern Machine Shop

Morris South

NETC

Next Generation Tooling

Oceanside Facility

Oktoberfest

Open House

Overgrip Collet

Part: Counterbore Drills

Part: Dental Drills

Part: Dental Impant

Part: Medical Device

Part: Surgical Drills

Part: Surgical Taps

PMTS

Press Release

Production Machining

Productivity Inc.

Ram Sales & Marketing

Schlenker

SIAMS

South Tec

South- Tec

Star CNC

Star SR20

STEM

Tech Tip

TF15

TF16

TF20

TF25

TF37

Todays Medical Developments

Tool Marketing Service

Trade Show

Trade Shows

Tsugami

UM10

UM10T

UM10W

UM5

UM5T

UM5V

UM5W

Videos

Workpiece Deflection

RSS Feed

RSS Feed