|

OCEANSIDE, CA. - At IMTS 2022 we where visited by the great folks at GIE Media, Inc. who publish Today's Medical Developments, Aerospace Manufacturing and Design and Today’s eMobility. They asked Matt Saccomanno, the inventor of the Microconic system to give them an on-camera overview of our products and how they work. As you probably already know, Masa’s Microconic Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface in your Swiss type CNC screw machine. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of shifting part operations from the main to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. At IMTS 2022, we expanded our Microconic line of swiss type CNC machine workholding. The new push type F15M5 and F16M5 cartridges replace the standard TF15 and TF16 collets in your CNC spindle. This enables you to use the newly introduced Microconic UM5 collet series with the Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. The off-the-shelf Microconic system concentricity of the cartridge and collet system combination is guaranteed to be within 5µm (0.0002") in production use. Both the F15M5 and F16M5 cartridges are a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F15M5 cartridge is compatible with spindles that accept Schaublin F15 76-580, E120, Southwick & Meister TF15 and Hardinge TF15 / 4607 collets, while the F16M5 cartridge is compatible with spindles that accept Schaublin F16 76-1076, E1212, Southwick & Meister TF16 and Hardinge TF16 / 4609 collets. Along with the new smaller cartridges comes a comprehensive series of UM5 collets that are ideally suited for small diameter part sizes ranging from 0.2mm/.008" to 5.5mm/.217" in diameter. These are available in regular type UM5 collets as well as all three types of Microconic's T, V and W type Over-Grip collets. Masa Tool offers the most unique variety of over-grip collets in the industry. And yes, if you listened closely to the video, you heard correctly, Matt spilled the beans on the new product that we'll be releasing next: The F13M5 Cartridge. And after that, we're going to heed that advise of "go big or go home. Yea, that was a spoiler alert.  The things that seems to excite Swiss machinists the most is our Micrograd™ wrench. The Micrograd Dial Wrenches provides a method of precisely setting clamping pressure on both the regular Microconic collets and on all series of Microconic over-grip collets. It can be adjusted in an infinite number of increments between the metric graduations of 0,02mm and inch/imperial graduations of .001" With the Micrograd Dial you can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

0 Comments

FOR IMMEDIATE RELEASE  Masa Tool's NEW products being introduced at IMTS 2022: The F15M5 & F16M5 cartridges and accompanying NEW UM5 collet series which includes over-grip collets and Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. CLICK THIS IMAGE TO ADD MASA TOOL'S IMTS BOOTH TO YOUR SHOW PLANNER OCEANSIDE, CA - Masa Tool has expanded their Microconic line of swiss machine workholding. The new push type F15M5 and F16M5 cartridges replace the standard TF15 and TF16 collets in your CNC spindle. This enables you to use the newly introduced Microconic UM5 collet series with the Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. The off-the-shelf Microconic system concentricity of the cartridge and collet system combination is guaranteed to be within 5µm (0.0002") in production use. F15M5 and F16M5 CartridgesBoth the F15M5 and F16M5 cartridges are a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F15M5 cartridge is compatible with spindles that accept Schaublin F15 76-580, E120, Southwick & Meister TF15 and Hardinge TF15 / 4607 collets, while the F16M5 cartridge is compatible with spindles that accept Schaublin F16 76-1076, E1212, Southwick & Meister TF16 and Hardinge TF16 / 4609 collets. UM5 Microconic ColletsAlong with the new smaller cartridges comes a comprehensive series of UM5 collets that are ideally suited for small diameter part sizes ranging from 0.2mm/.008" to 5.5mm/.217" in diameter. These are available in regular type UM5 collets as well as all three types of Microconic's T, V and W type Over-Grip collets. Masa Tool offers the most unique variety of over-grip collets in the industry. Micrograd UM5 Dial WrenchA full set of UM5 accessory products has also been introduced including a a UM5 series of Microguide EGS™ ejection guide sleeves and a new UM5 Micrograd™ Dial Wrench which is included with the purchase of any of the Microconic Cartridges. Mircrograd Dial Wrenches for the UM5 collets are now available in both metric, CW5-M, and imperial increments CW5-E. The Micrograd™ Dial Wrenches provides a method of precisely setting clamping pressure on both the regular Microconic collets and on all series of Microconic over-grip collets. It can be adjusted in an infinite number of increments between the metric graduations of 0,02mm and inch/imperial graduations of .001" With the Micrograd Dial you can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel". Microconic: Game Changing Technology for Small PartsMasa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of shifting part operations from the main to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. These new cartridges, collets and accessories will be demonstrated for the first time at IMTS 2022 in the West Building, Level 3 — 432163 — Tooling & Workholding Systems IMTS Press BriefingJoin Masa Tool at Booth 432163 West Building, Level 3 TUESDAY SEPTEMBER 13 AT 3:30PM central time We will introduce our NEW Microconic products for Swiss-type CNC Workholding! Featuring Masa Tool's expands its Microconic system at IMTS 2022: The F15M5 & F16M5 cartridges and accompanying NEW UM5 collet series which includes over-grip collets and Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure

A Swiss CNC machine shop presented us with several problems related to long cycle times and poor tool life with a high-volume group of Dental Surgical Drills, Taps, and Counterbore Drills with standard ISO shank configuration.

Before Microconic: The Workholding ProblemsBefore implementing the Microconic solution there were a number of problems:

Matt goes on to explain how the Microconic System solves all of the problems with traditional pickoff collet with a guaranteed 0002" TIR accuracy and ships everything from stock within two days of placing an order! Masa Tool's Microconic cartridge is made of exotic high-chromium tool steel, triple tempered and cryogenically treated to provide stable construction. All functional seating surfaces are ground with extreme precision on a one-piece, ultra-rigid body structure.

“The cartridge can be used as a calibration gage to verify the machine spindle accuracy,” Co-owner Chip Prescott notes. Microconic collets are finished to exacting standards with a five-step grinding process that removes the effect of heat-treat warpage. Also, the proprietary Microconic form of the closure surfaces is inherently more accurate than traditional collets, providing for a greater full-accuracy working range. Cartridges are available to fit in push-type dead-length collet closers and also draw-type closers: F20M10 (for TF20 collet replacement), F25M10 (for TF25 collet replacement), and 5CM10 (for 5C collet replacement). All of these cartridges use the same Microconic UM10 collets, with more cartridge sizes in development to be released soon. Matt Saccomanno, the Co-Founder of Masa Tool and inventor of the Microconic Workholding sytem will talking about process innovations in the metalcutting manufacturing industry during the International Manufacturing Technology Show, IMTS, in September at McCormick Place in Chicago, IL. Swiss-type CNC machines have gained in capability and demand as the machined components they produce are trending toward higher precision and micro-sized features. As the machines have become more sophisticated, the underlying basics of workholding remained unchanged until recently.

This presentation is an overview of new developments as well as traditional approaches with relevance to today’s highly capable sliding headstock “Swiss-type” CNC turning centers. The goal is to summarize best-practices for optimizing use of both main and sub-spindle to maximize productivity and overall equipment effectiveness. The material presented is useful for machinists, CNC programmers, tool crib personnel, manufacturing engineers, estimators, and hands-on managers. If you would like to reserve your spot in this technical presentation and discussion please click the below button. Set ups are quicker and more repeatable with Microconic™. You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

How to use the Micrograd™ Face Dial Wrench

For a complete set of instructions please see our installation procedures for more details on how to set up and replicate your clamping pressure on every machine in your shop.

The Microconic Workholding system was featured at the Marubeni Citizen-Cincom of New England booth at the Eastec 2017 Machine Tool Show! Marubeni Citizen-Cincom is the exclusive New England distributor for Citizen Cincom Swiss style lathes and Miyano Multi Axis turning centers as well as ne of our premier distributors of the Micorconic Workholding system About the CINCOM L20 Low Frequency Vibration (LFV)State-of-the-art LFV is a widely applicable cutting technology designed to avoid the problem of spiraling chips, entanglement of chips and built-up edges. Benefits include increased cutting tool life, reduced heat generation and reduced power consumption.

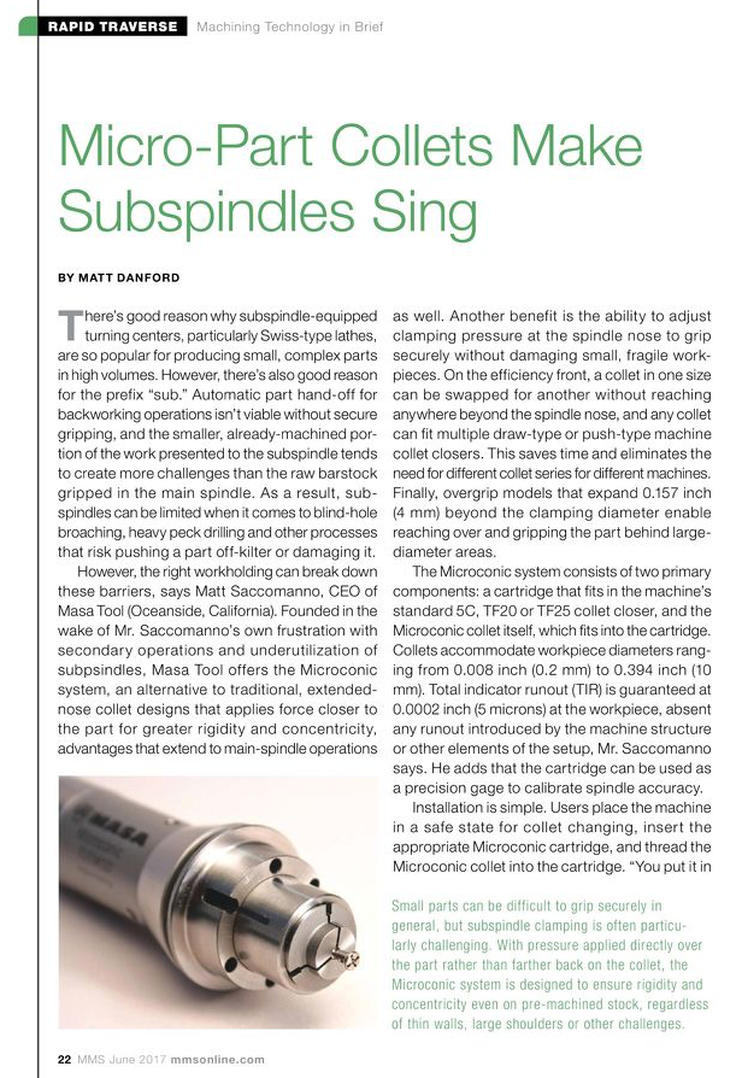

The popular Citizen CINCOM L20 series sliding headstock lathes are now available with Low Frequency Vibration (LFV). This widely applicable cutting technology – able to handle a broad range of machining shapes and materials – is ideal for cutting difficult-to-cut materials. The state-of-the-art LFV suppresses various risks associated with these materials, such as entanglement of chips and built-up edges. Depending on the material being cut, a variety of problems can be caused by chips getting entangled with each other, including increased cutting resistance, scarring, changes in the texture of the machined surface, tool nose damage, and built-up edges due to cutting heat. In LFV cutting, “air cutting” time prevents the machining temperature from rising, which both prolongs tool lives and gives relief from various problems caused by chips. Masa Tool is introducing its Microconic workholding system for use in subspindle Swiss-type machine operations, enabling the operator to switch operations from the main to the subspindle so that usage is balanced. Masa Tool is introducing its Microconic workholding system for use in subspindle Swiss-type machine operations, enabling the operator to switch operations from the main to the subspindle so that usage is balanced. This capability is said to reduce cycle time in ways that are not possible with conventional collets. The Microconic system consists of two primary components: a cartridge that fits in the machine’s standard TF20, TF25 or 5C collet closer, and the collet itself, which fits into the cartridge. Each cartridge model has a solid extended nose and can accept both regular and over-grip collets. The over-grip collets open up to 0.157" (4 mm) larger than the clamping diameter. The Microconic cartridge’s extended nose design directs all of the chucking pressure directly over the workpiece for concentricity and rigidity. Total indicated runout (TIR) for the Microconic system is guaranteed at 0.0002" (5 µm) at the workpiece, absent any runout introduced by the machine structure or other elements of the setup. The system capacity ranges from 0.008" to 0.394" (0.2 to 10 mm) in diameter, with all sizes available from stock.

We got a very unexpected present in the mail this past week! We where very excited to learn that our Microconic workholding system for small diameter part machining was featured in the Rapid Traverse section of the June 2017 issue of Modern Machine Shop!!! We've got pictures of the article below in case you don't currently subscribe to Modern Machine Shop. You can also download a PDF copy of the entire June issue below in the link. It starts on Page 25 of the PDF download. If you have the print edition it's on Page 22, or you can just read thought the screen shots below. We want to really extend a very big THANK YOU to Matt Danforth at Modern Machine Shop who wrote this article. Matt really did an awful lot of work learning about the various features of our system. We know there where many many hours that he spent to develop this story just from the sheer number of follow up questions and conversations. We really have an awful lot of respect for the entire MMS team and the effort they put into getting their story's "just right".

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

||||||||||||||||||

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed