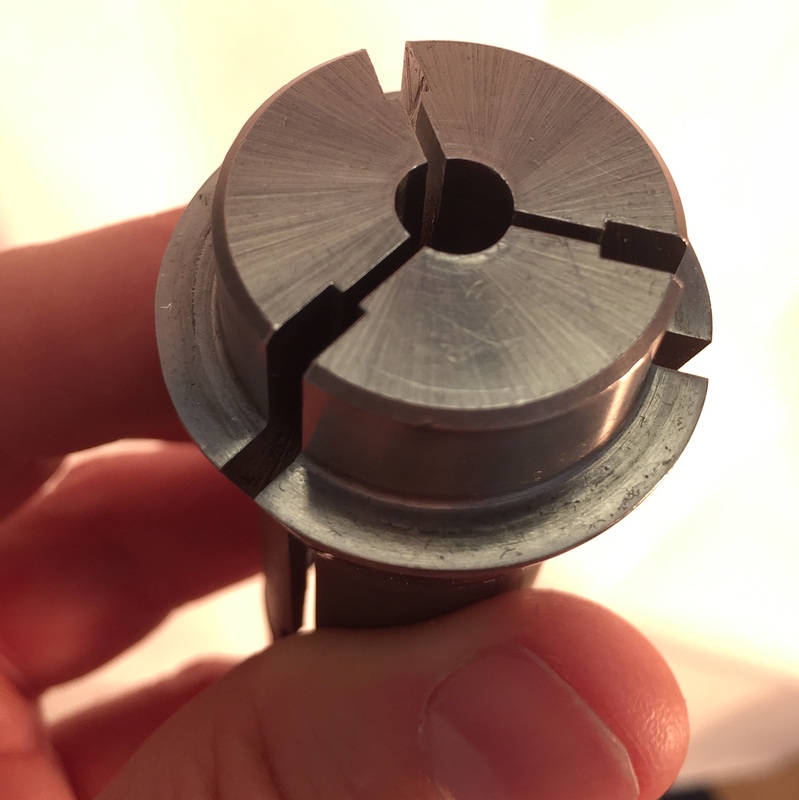

Cascading Failures stopped by Precision, Hardened & Ground Microconic UM collet for Dental Implant9/30/2015 Our customer was machining 6Al4V Titanium dental implants and scrap rates increased the longer our competitors collets where in use. This root cause was primarily result of cutting the threads in the main spindle. Chips wrapped around the finished threads before the implant was handed over to the sub spindle collet for machining of the head hex and internal thread. Collet wear & bad parts

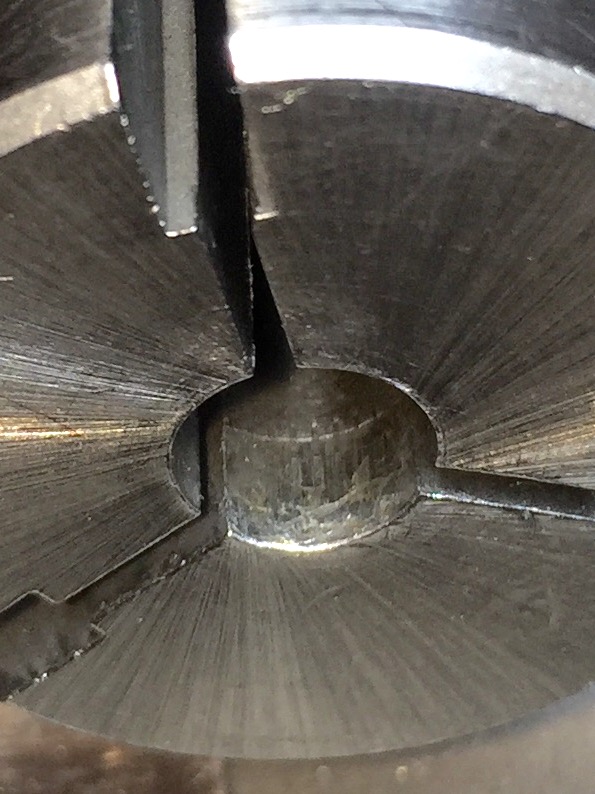

The unpredictable periodic clamping on the wrapped chips on the workpiece embedded chip impressions in the collet (Fig. 3) which in turn marked the next part when it was chucked on.

As a result the competitor's collet workholding lost it's chucking power from the bell mouthing in the front. By becoming out of round, parts lost their concentricity.

5 Comments

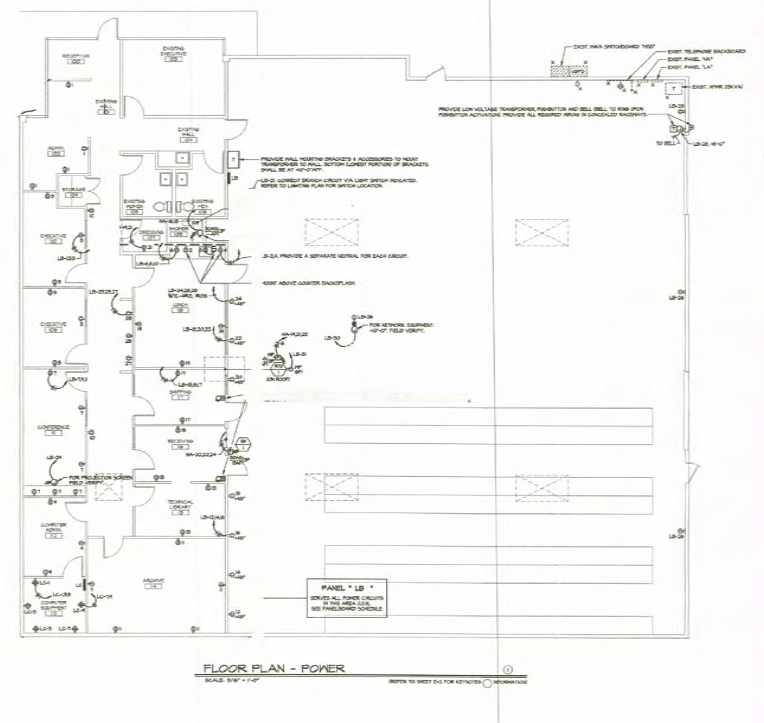

Masa Tool moved into it's new manufacturing facility in Oceanside, CA, located midway between Long Beach and San Diego to serve our growing customer base with increased production capacity, sales and service, plus an extensive inventory of products. Masa Tool serves the automotive, aerospace, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of CNC machine tool OEM’s worldwide.

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed