|

Matt Saccomanno, the Co-Founder of Masa Tool and inventor of the Microconic Workholding sytem will talking about process innovations in the metalcutting manufacturing industry during the International Manufacturing Technology Show, IMTS, in September at McCormick Place in Chicago, IL. Swiss-type CNC machines have gained in capability and demand as the machined components they produce are trending toward higher precision and micro-sized features. As the machines have become more sophisticated, the underlying basics of workholding remained unchanged until recently.

This presentation is an overview of new developments as well as traditional approaches with relevance to today’s highly capable sliding headstock “Swiss-type” CNC turning centers. The goal is to summarize best-practices for optimizing use of both main and sub-spindle to maximize productivity and overall equipment effectiveness. The material presented is useful for machinists, CNC programmers, tool crib personnel, manufacturing engineers, estimators, and hands-on managers. If you would like to reserve your spot in this technical presentation and discussion please click the below button.

0 Comments

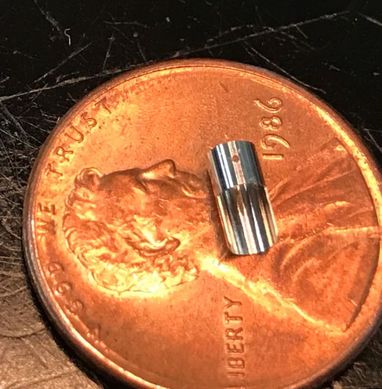

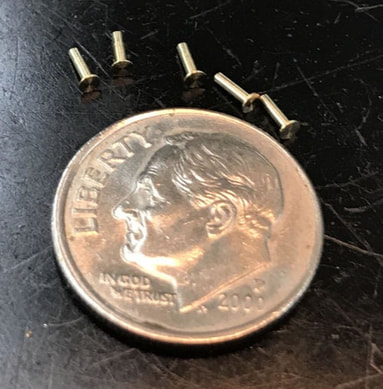

CEDAR GROVE, NJ. - Metal Cutting Corporation is an independent metal fabricating company that specializes in the burr-free abrasive cut-off of metal parts and the related grinding, lapping, polishing, turning and EDM. They manufacture precision metal components for a diverse range of industries, including medical device, automotive, electronic, biotechnology, semiconductor, aerospace, fiber optic, electrical and general mechanical industries.

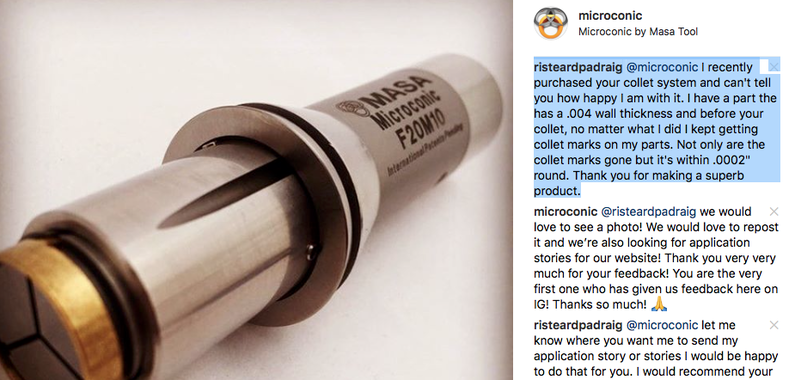

That comment lead to us wanting to learn more about how Metal Cutting was using our workholding! This is the very first application success story that has been shared with us on Instagram. Rich was kind enough to send us some information about how he came to be using Masa Tool.

About Metal Cutting Corporation Metal Cutting Corporation was founded in 1967 and moved to their current 52,000 square foot manufacturing facility in 1998. In 2008 they expanded their existing machine shop capabilities with Haas and subsequently Citizen turning equipment, allowing them to offer multi-axis CNC milling, lathe and automatic Swiss style machining up to 7 axes. Their specialty has always been small diameter parts made from all metals. "The parts can be long but are most often short, often very short." When the company started in the late 1960's they primarily worked with non-ferrous metals, especially tungsten and molybdenum. So much so that in 1984 they became the exclusive North American distributor for Nippon Tungsten Co., Ltd.’s tungsten and molybdenum products. Since the the 1980's they have been working with and machining more stainless steel and now have a developed a deep knowledge of machining the newer nickel and titanium based alloys.

Over the past several months Rich has been able to apply the Microcnic system to several other products that they make in their Citizen Machines.

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed