|

A proprietary grinding process and the application of clamping force exactly where it’s needed ensure secure, concentric gripping with a collet system that can potentially fit every turning machine in a shop. Blog: 2/17/2017 by MATT DANFORD Associate Editor, Modern Machine Shop There’s good reason why subspindle-equipped turning centers, particularly Swiss-type lathes, are so popular for small, complex parts produced in high volumes. However, there’s also good reason for the prefix “sub.” Automatic part hand-off for backworking operations isn’t viable without secure gripping, and the smaller, already-machined portion of the work presented to the subspindle tends to create more challenges than the raw barstock gripped in the main spindle. As a result, subspindles can be limited when it comes to blind-hole broaching, heavy peck drilling and other processes that risk pushing a part off-kilter or damaging it.

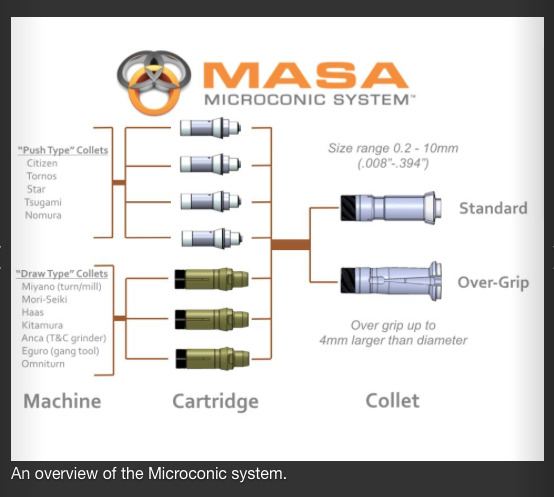

Finally, overgrip models that expand 0.157 inch (4 mm) beyond the clamping diameter enable reaching over and gripping the part behind large-diameter areas.

Installation is simple. Users place the machine in a safe state for collet changing; insert the appropriate Microconic cartridge; and thread the Microconic collet into the cartridge. “You put it in your spindle and leave it there,” Mr. Saccomanno says about the three cartridge models, each of which can accept any standard or over-grip collet. This capability enables switching to a different-diameter collet for a different-diameter part and setting the correct chucking force in roughly 2 minutes, compared to the 15 minutes it might take to swap, say, a TF25 collet, he says.

In addition to better facilitating secure clamping without damaging thin-walled or otherwise delicate workpieces, self-contained, dial-micrometer force adjustment helps ensure setups aren’t affected by temperature fluctuations that might subtly alter the machine structure between collet-closer and collet. As Mr. Saccomanno puts it, “From the first part in the morning to the last part on second shift, it grips the same. You don’t have to play with it throughout the day.”

“Traditionally, you’ll see wear closer to the slots rather than in the center, between the slots,” he says. “There’s no uncertainty about whether (a Microconic collet) will touch on the left or the right side first. That’s where you’ll get some variation in traditional designs.”

Granted, Mr. Saccomanno recommends using programmed cycle stops while validating a production setup to ensure part ejection is reliable. Nonetheless, combined with the precision and gripping security common to all Microconic collets, capability for extreme overgripping can enable “doing things on the subspindle that you never would have dreamed of before,” he says.

0 Comments

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed