|

Be sure to join Matt Saccomanno, President of Masa Tool, presentation on boosting profitability by taking advantage of improvements in sub spindle workholding on Swiss-style CNC Machines. IMTS Conference: Boosting Profits from Swiss-type Machines by Better Use of the Sub-Spindle Wednesday, September 14 • 10:00 AM - 10:55 AM Central This is a presentation of new and advanced techniques for gaining productivity from Swiss-type CNC machines, with emphasis on maximizing utilization of the machine’s counter-spindle (“sub-spindle”). Essentially a fully capable machine within a machine, the sub-spindle is rarely used at more than 20% efficiency, which is a huge waste of productive capacity. Most of the roadblocks to increased usage stem from the limitations of traditional workholding. The presentation is loaded with real-life examples and practical do-right-now techniques. Swiss-type CNC turning centers are gaining in popularity as the parts they produce trend toward higher precision and micro-sized features. To be competitive, smart use of the machine’s full capabilities is a big advantage. Achieving “lights out” production and minimizing machine cycle times are key tactical objectives. Join Matt Saccomanno, co-founder and CEO of Masa Tool, as he explains advanced work holding techniques that fundamentally change the scope of what is possible on a Swiss-type machine (also known as “sliding head” or guide bushing machine). Balancing the main and sub-spindle cycle times, achieving reliable untended , lights out production, and reducing scrap and down time will be the focus of this informative and interactive presentation. Much of this material is also applicable to other types of machining centers, especially when making small parts. Bring your real-world “problem parts” to the session for a strategy discussion with Mr. Saccomanno. This session is beneficial for machinists, CNC programmers, manufacturing engineers, tool crib personnel, and hands-on managers. About the Speaker

About Masa Tool Inc.With deep roots in the Swiss-type screw machine industry, Masa Tool Inc. was founded in Oceanside California with the mission of bringing the Microconic System to the world. This revolutionary workholding system consists of the Microconic “cartridge” and “collet”. It was invented to solve the problems created by traditional long nose collets commonly used in the sub-spindle of screw machines for over 100 years.

As screw machines evolved from mechanical cams in the late 1900’s to today’s CNC controls, the complexity of parts being made increased dramatically. Making these modern micro precision parts complete on the machine without additional secondary operations became critical to remain competitive. Using the machine’s sub-spindle to complete the part is a must. As the demands for precision and complexity increase, the traditional long-nose collet has many limitations that can frustrate the machinist trying to get the most out of the machine. We created the Microconic system to overcome these limitations of conventional collets. The result is superior rigidity, accuracy, over-grip capability, clamping force control, and long-run stability. We at Masa built our company from the ground up to ensure that everything in our catalog is available to ship within 2 days. Every size, every type. We currently offer any size from 0.2mm – 10mm diameter (.008” - .394”).

0 Comments

by Matt Saccomanno Hi everybody! It’s been a fantastic trip and an amazing closing day to the SIAMS 2022 exhibition! A hectic schedule and more talking and trying to decipher French than I’m built for, but super worthwhile. SIAMS is in the village of Moutier, in the heart of the “Jura” region, which spans a distinct area in the lower mountains overlapping the border of Switzerland and France. It is the historic center of the Swiss watch industry, but also is a dense cluster of high precision manufacturing like probably no other in the world. For our customer base of “Swiss-type” machining (“décolletage” in French), you literally can find the best of everything, including the awesome products of a particular company in Oceanside California.

Unlike in the past, Masa is now known and very much respected. I was often introduced almost like visiting royalty as “Mr. Masa”. Several people even commented “You cut your hair” (in French of course), having seen the early video Bernie took of me describing the product at IMTS 2016. We are still the new kids on the block, but known and perhaps even admired.

I can’t say this without tears in my eyes how so very proud and grateful I am for the integrity and effort everyone puts into making Masa the literal BEST in the world at what we do! With joy and gratitude, Matt About SIAMS -The trade fair for microtechnology production tools located in the center of the regional Jura industry, SIAMS unites every two years the players of the industry and presents the means of production of microtechnology. This fair created to respond to the specific concerns of precision-industry entrepreneurs presents an ideal technology platform with more than 450 specialized exhibitors.

At SIAMS, the entire microcosm or "ecosystem” of microtechnology is represented:

Machinery equipment, assembly measurement, control, and quality assurance automation tools, accessories, mechanics raw materials semi-finished products metalworking – suppliers plastics processing installation service companies organizations. Matt Saccomanno, the Co-Founder of Masa Tool and inventor of the Microconic Workholding sytem will talking about process innovations in the metalcutting manufacturing industry during the International Manufacturing Technology Show, IMTS, in September at McCormick Place in Chicago, IL. Swiss-type CNC machines have gained in capability and demand as the machined components they produce are trending toward higher precision and micro-sized features. As the machines have become more sophisticated, the underlying basics of workholding remained unchanged until recently.

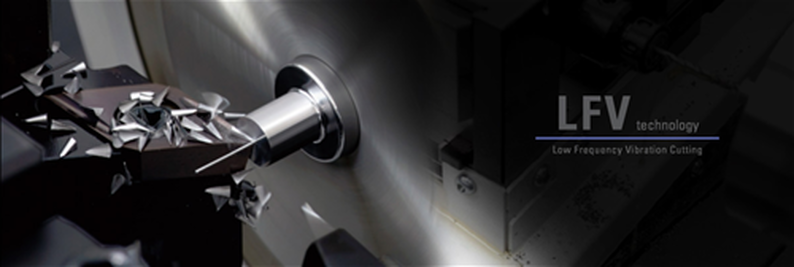

This presentation is an overview of new developments as well as traditional approaches with relevance to today’s highly capable sliding headstock “Swiss-type” CNC turning centers. The goal is to summarize best-practices for optimizing use of both main and sub-spindle to maximize productivity and overall equipment effectiveness. The material presented is useful for machinists, CNC programmers, tool crib personnel, manufacturing engineers, estimators, and hands-on managers. If you would like to reserve your spot in this technical presentation and discussion please click the below button. The Microconic Workholding system was featured at the Marubeni Citizen-Cincom of New England booth at the Eastec 2017 Machine Tool Show! Marubeni Citizen-Cincom is the exclusive New England distributor for Citizen Cincom Swiss style lathes and Miyano Multi Axis turning centers as well as ne of our premier distributors of the Micorconic Workholding system About the CINCOM L20 Low Frequency Vibration (LFV)State-of-the-art LFV is a widely applicable cutting technology designed to avoid the problem of spiraling chips, entanglement of chips and built-up edges. Benefits include increased cutting tool life, reduced heat generation and reduced power consumption.

The popular Citizen CINCOM L20 series sliding headstock lathes are now available with Low Frequency Vibration (LFV). This widely applicable cutting technology – able to handle a broad range of machining shapes and materials – is ideal for cutting difficult-to-cut materials. The state-of-the-art LFV suppresses various risks associated with these materials, such as entanglement of chips and built-up edges. Depending on the material being cut, a variety of problems can be caused by chips getting entangled with each other, including increased cutting resistance, scarring, changes in the texture of the machined surface, tool nose damage, and built-up edges due to cutting heat. In LFV cutting, “air cutting” time prevents the machining temperature from rising, which both prolongs tool lives and gives relief from various problems caused by chips.

Productivity's 2017 Oktoberfest Tool Show website is live! Check out this year's Oktoberfest Tool Show, being held from September 26-28 at Productivity Inc, Plymouth, MN.

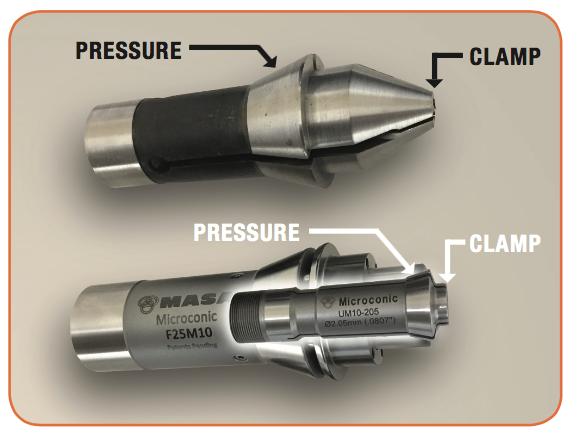

Masa Tool is very excited to again participate in Productivity Inc's 19th Oktoberfest Tool Show. We're looking forward to showcasing our Microconic Workholding sytems for swiss style CNC lathes at their marvelous facility. Matt Saccomanno, CEO of Masa Tool, and the inventer of the Microconic system will be on hand with our regional managers for the area, High Tech Industrial, to answer all of your technical & applicaiton questions. Let's get productive! Productivity's Oktoberfest Tool Show gives you more tools to help grow your business with over 40 machine tools and technologies on display as well as over 80 tooling lines on display! See the newest machine and tooling technologies, witness live machine demos and attend one of 12 informative seminars. Show hours are 8:30 am to 6:00 pm daily. Go to http://www.productivity.com/oktoberfest-tool-show/ for more details and to register. Let us know you're going by clicking the JOIN button HERE! Masa Tool is introducing its Microconic workholding system for use in subspindle Swiss-type machine operations, enabling the operator to switch operations from the main to the subspindle so that usage is balanced. Masa Tool is introducing its Microconic workholding system for use in subspindle Swiss-type machine operations, enabling the operator to switch operations from the main to the subspindle so that usage is balanced. This capability is said to reduce cycle time in ways that are not possible with conventional collets. The Microconic system consists of two primary components: a cartridge that fits in the machine’s standard TF20, TF25 or 5C collet closer, and the collet itself, which fits into the cartridge. Each cartridge model has a solid extended nose and can accept both regular and over-grip collets. The over-grip collets open up to 0.157" (4 mm) larger than the clamping diameter. The Microconic cartridge’s extended nose design directs all of the chucking pressure directly over the workpiece for concentricity and rigidity. Total indicated runout (TIR) for the Microconic system is guaranteed at 0.0002" (5 µm) at the workpiece, absent any runout introduced by the machine structure or other elements of the setup. The system capacity ranges from 0.008" to 0.394" (0.2 to 10 mm) in diameter, with all sizes available from stock.

The Microconic system will be able to do things that are impossible |

| Our regular MicroconicTM collets help reduce cycle time by allowing a rm grip on the workpiece without causing damage, and yet holding it much more rigidly than any other collet on the market. You’ll be able to do heavy machining operations in the sub spindle, such as blind hole broaching, that would not have even considered in the past. Now you can switch ops from main to sub! Set ups are quicker and more repeatable with Microconic. You can document the micrometer-adjust collet closure in your set up plan using our Micrograd Face Dial Wrench and it’s going to repeat to the same clamping pressure each and every time, regardless of operator skill and without relying on “feel”. You can calibrate your spindle accuracy with the MicroconicTM cartridge by using it as a precision cylinder gauge. When that is good, EVERY Microconic collet will run within .0002” TIR: There’s no ddling and swapping collet after collet looking for a “good” one. Set ups go smoothly and predictably. | The Microconic collets fit into our cartridge to hold the workpiece with great precision and rigidity. Unlike traditional extended nose collets our unique design and closing action is inherently more accurate and consistent. The clamping force is directly over the workpiece at the end of the collet. The origin of the word “Microconic”, alludes to the precise way in which the collet closing taper is formed to cancel the effects of heat treat warp and grind tolerances. As a result, it provides industry- best concentricity every time. |

Download or View the 2017 Masa Tool Microconic Catalog:

You can check out our segment starting at 8 minutes into the video! We want to extend a very big thank you to Marubeni Citizen for putting our system as a feature of their very latest in technology!

We discussed that many many people had just given up on trying to find a solution for balancing out production between the main spindle and the sub-spindle years and years ago. We where even more excited than most of the people that stopped by our booth to learn that we had indeed invented something that fixes the problem!

|

A big thank you to the folks at AMT and IMTStv who interviewed us at the show for the big screen!!

"If you manufacture small parts, you have to see this microconic system, it's no ordinary collet! Check out what we found in the west hall at Microconic by Masa Tool's booth W-2232!" Watch more videos at IMTS.com/IMTSTV |

|

Author

Here you will find the latest press releases, news coverage and technical information about our Microconic™ system

Archives

February 2023

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

January 2022

October 2021

May 2021

July 2020

March 2020

February 2020

December 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

June 2017

May 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

March 2016

February 2016

January 2016

December 2015

November 2015

October 2015

September 2015

August 2015

July 2015

May 2015

April 2015

August 2014

May 2014

March 2014

July 1999

Categories

All

5C Cartridge

5C Collet

Advanced Manufacturing

Advertisement

Agent Profile

AMTS

APT Machine Tools

Avinger

Bell Mouthing

Bone Screws

Case Study

Catalog

CEO CFO

Chip Wrapping

Cincom

Cincom L12

Cincom L20

Cincom M16

Cincom M32

CNC West

Collet

Concentricity

Dental Implants

Dragan Marjanovic

Dunner SA

Eastec

Ejection Guide Sleeve

Emergency Collet

F13M5

F15M5

F16M5

F201M10

F20M10

F37M10

Floyd Automatic

Ganesh

High Tech Industrial

IMTS

ISwiss

Jones Marketing

Lane 4

Machinery Trade International

Magazine Article

Mann Sales

Marubeni Citizen

Material: 6Al4V

MAV Innovations

Metal Cutting Corp

Microconic

Micrograd Wrench

Microguide Sleeve

Micromachining

Micro-Matics

Modern Machine Shop

Morris South

NETC

Next Generation Tooling

Oceanside Facility

Oktoberfest

Open House

Overgrip Collet

Part: Counterbore Drills

Part: Dental Drills

Part: Dental Impant

Part: Medical Device

Part: Surgical Drills

Part: Surgical Taps

PMTS

Press Release

Production Machining

Productivity Inc.

Ram Sales & Marketing

Schlenker

SIAMS

South Tec

South- Tec

Star CNC

Star SR20

STEM

Tech Tip

TF15

TF16

TF20

TF25

TF37

Todays Medical Developments

Tool Marketing Service

Trade Show

Trade Shows

Tsugami

UM10

UM10T

UM10W

UM5

UM5T

UM5V

UM5W

Videos

Workpiece Deflection

RSS Feed

RSS Feed