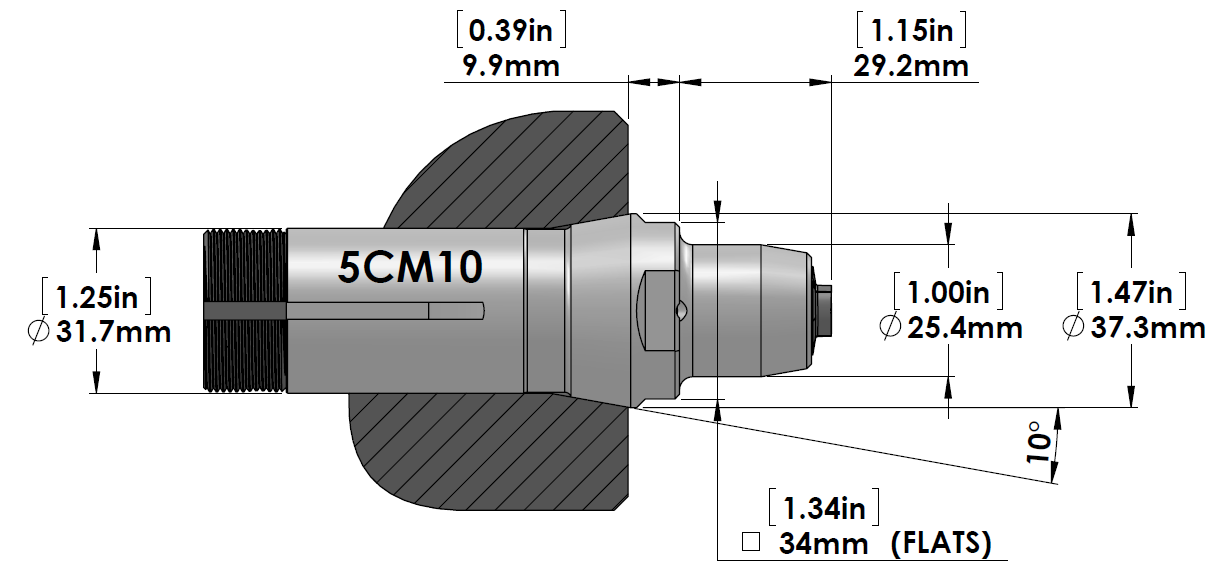

5CM10 Cartridge

The pull type 5C Microconic™ Cartridge replaces the standard 5C collet in your CNC spindle. This enables you to use our Microconic™ collets to achieve concentricity guaranteed to be within 5µm (0.0002") in production use.

The 5C Cartridge a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time.

Compatible with spindles that accept Hardinge 5C and Schaublin W31.75 80-842, E385 collets.

The 5C Cartridge a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time.

Compatible with spindles that accept Hardinge 5C and Schaublin W31.75 80-842, E385 collets.

5C collets are some of the most widely used and versatile clamping methods used in metalcutting lathes and mills today but have never been able to provide the accuracy and rigidity often needed for small diameter parts. Until now...

Development of the the 5C cartridge dates back to the late 1990's but this newly introduced version is manufactured using our unique "Microconic" production method that provide more accuracy and rigidity than was possible with any other "off-the-shelf" rotating clamping system.

The “Microconic™ System” is a miniaturized collet system that consists of two major components: the Microconic™ “cartridge” that fits directly into 5C spindles and the Microconic™ collets that is a “right size” style collet.

The “Microconic™ System” is a miniaturized collet system that consists of two major components: the Microconic™ “cartridge” that fits directly into 5C spindles and the Microconic™ collets that is a “right size” style collet.

If you have any secondary gang-tool or turret lathes with 5C collet system you will LOVE the Microconic 5CM10 cartridge. Better tool clearance with the extended nose. Micrometer control of collet closure regardless of hydraulic/pneumatic/manual collet closing mechanism of the machine. Unbeatable concentricity.

Holding Power:

Masa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of moving part operations to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved.

Masa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of moving part operations to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved.

|

|

5CM10 Features

|

Find your Collets for the F25M10 Cartridge

Masa Tool introduced 5C Microconic™ cartridge in 2016. It maintains 5 µm concentricity and is now available for machining centers, CNC lathes, CNC mills, gang-tool lathes, like Omniturn, CNC mill/turn, like Nakamura, Miyano, Mori-Seiki, and even rotary indexers as well as tool and cutter grinders!

Micrograd Dial Wrench

|

Our CW10 Micrograd™ Dial Wrench is included with the purchase the 5CM10 Microconic Cartridges.

The Micrograd™ Dial Wrench provides a method of precisely setting clamping pressure on both the Microconic collets and an Microconic overgrip collets . It can be adjusted in metric increments of 0,02mm and imperial increments of .001" |

|