This article originally appeared in the April 2017 issue of Today's Medical Developments. It was the cover story entitled: "Micro-Precision Machining" by Elizabeth Modic The Microconic system benefits orthopedic bone screws, miniature precious metal components for pacemakers, and other implantables; machined surgical components made of hypodermic needle tubing; and surgical instrument components. Here’s one example – dental implants.

Cost savings: Production rate went from 18pph to 32pph, a 44% cost savings. In addition, a hand deburring operation was eliminated due to the cut-off being on the opposite end. ROI: Cost of the Microconic system was recouped in 64 production hours; a $14,015 saved in direct production costs of a 10,000-piece order. About the author: Elizabeth Modic is the editor of Today’s Medical Developments and can be reached at [email protected] or 216.393.0264.

0 Comments

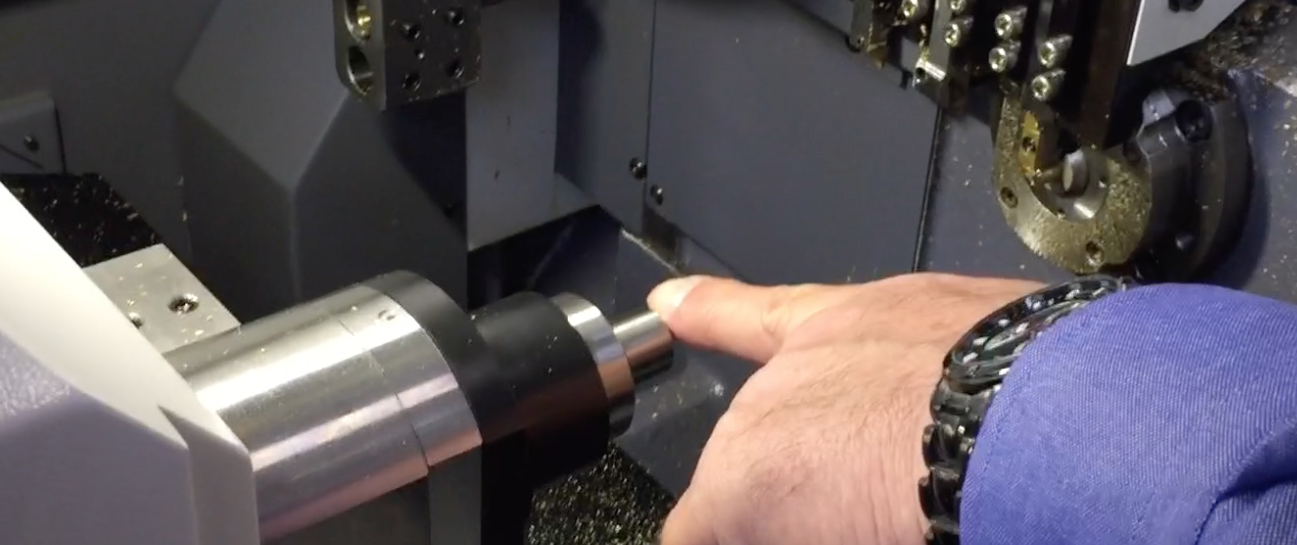

The below article excert originally appeared in Advanced Manufacturing magazine. You can read the entire article at the title link at the bottom of this page. Workholding Advances Medical parts are often delicate, which can create problems when they are picked off with the subspindle for backwork. It is important but difficult to apply just the right amount of pressure to hold the part in the subspindle. And once the optimum gripping force is determined, it is not easy to communicate to other operators how the adjustment was made. Machine tool accessory maker Masa Tool Inc. (Oceanside, CA) has developed a collet system that makes this process easier. The collet is set using a special tool with marked graduations that enable precise adjustments to the gripping force of the collet. “You can document the micrometer-like adjustment for the collet closure in your setup plan,” said Matt Saccomanno, CEO. “It’s done the same way every time, regardless of operator skill and without relying on feel.” One of the more challenging Swiss applications is making dental implants because of their small size. Saccomanno said that Masa recently helped a customer broach a dental implant on the subspindle with the Masa collet system holding only a small land. Considering how much force is applied to the workpiece during a broaching operation, this might have seemed impossible to accomplish. The reason it is possible is that the Masa collet system applies the gripping forces directly over the area where the collet grips the part. The collet system has two main parts, a cartridge that replaces the standard machine collet and a smaller collet made by Masa that is installed into the cartridge. These components are held to a high accuracy and are made by Masa with proprietary grinding methods. Concentricity variation is held to 0.0002″ (0.005 mm). “This particular broaching application used an over-grip collet,” Saccomanno said. “The process change moved an operation from the main-spindle to the subspindle and so allowed some simultaneous machining not possible previously. Before they used our system, the part was made entirely on the main spindle.” An over-grip collet opens up to pass over a shoulder or some other feature on a part in order to grip the part past the shoulder. Masa makes over-grip collets that can open up to 4 mm over the chucking diameter. This is the largest difference in diameter in the industry and still holds 0.0002″ TIR, according to Masa. Read the entire article by clicking the link below

Special Thanks to Mark Hurst from HiTech Industrial for bringing this application solution to their attention.

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed