FAQ's

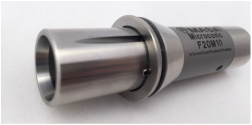

What is Microconic™?

Microconic™ is based upon the 5 step grinding process combined with our unique design that has been developed over a 15 year period to bring you the most accurate TIR with adjustable clamping for small part diameters.

Microconic™ is based upon the 5 step grinding process combined with our unique design that has been developed over a 15 year period to bring you the most accurate TIR with adjustable clamping for small part diameters.

|

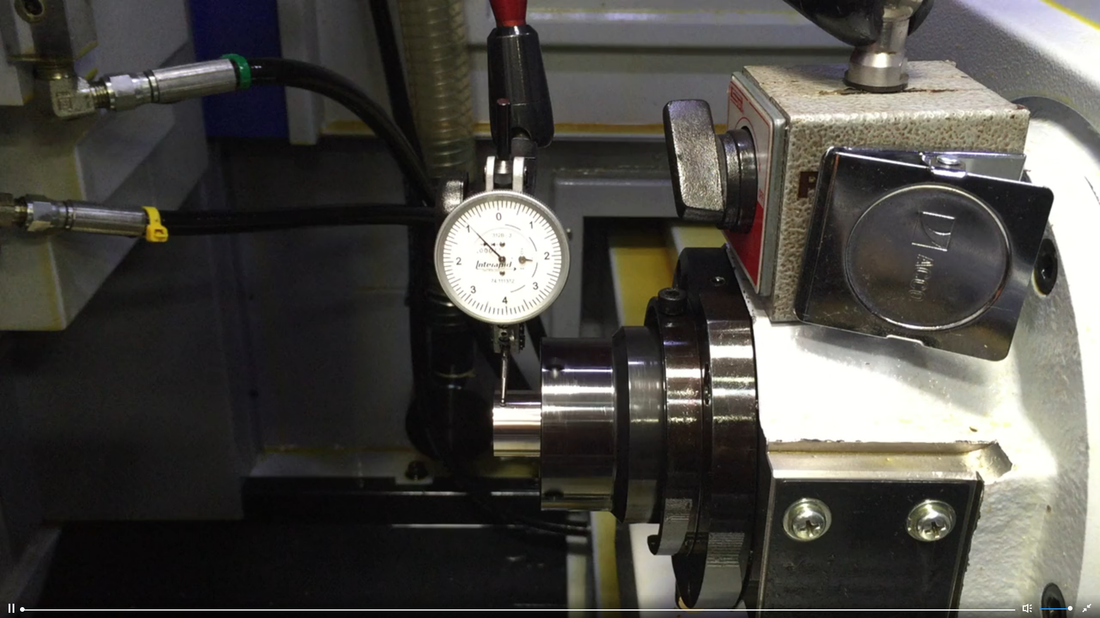

How do you measure Concentricity?

Concentricity is measured in terms of Total Indicator Runout (TIR). A gage pin is inserted in the collet and the TIR is measured at a set distance (2 diameters?) from the spindle face, depending on the order hole size, using a .00005" dial indicator. You can be assured of a qualified inspection – standard 10mm collets will run .0001" to .00015" (3 microns) concentricity, and guaranteed to be within 0.0002" (5 microns) in production use. This assures that the collet will hold your part consistently during your specified machining operations. |

|

Does your 5C microconic cartridge comply with DIN 6341 355E?

When introduced in December 2015 the 5C cartridge will meet and/or exceed the specifications of DIN 6341 355E. So, the short answer is "Yes!"

When introduced in December 2015 the 5C cartridge will meet and/or exceed the specifications of DIN 6341 355E. So, the short answer is "Yes!"

What is the difference between concentricity and TIR?

- Circular runout is a two-dimensional measurement using surfaces to control an axis. The tolerance is applied at any cross-section. When it is used on a surface referenced to a datum axis, as with this part, it will control the total sum of all variations of circularity and coaxiality.

- Concentricity is more complex. It can be thought of as three dimensional and uses a series of diameters and their midpoints to generate an axis location. This is why the process control operators like it: It gives an XY location of how the two axes line up. [READ MORE]

SPECIAL NOTE: Circular runout does not control the perpendicularity of a planar surface. It just equalizes material on each side of the datum axis, so that it doesn't wobble when rotated. Total runout does control flatness and perpendicularity of a planar surface to a datum axis. So, if you want the planar surfaces to be perpendicular to datum axis A, just replace the single arrow (circular runout) with the double arrow (total runout).

Both Circular Runout and Total Runout are defined as a "surface to datum axis control". If used on a diameter, circular Runout controls roundness and concentricity to the datum axis. Total runout controls roundness, straightness, taper, and concentricity, if used on a cylindrical diameter.

Circular Runout controls balance of material on each side of the datum axis, if used on a planar (flat) surface. Total Runout controls flatness and perpendicularity to the datum axis, if used on a planar (flat) surface.

Both Circular Runout and Total Runout are defined as a "surface to datum axis control". If used on a diameter, circular Runout controls roundness and concentricity to the datum axis. Total runout controls roundness, straightness, taper, and concentricity, if used on a cylindrical diameter.

Circular Runout controls balance of material on each side of the datum axis, if used on a planar (flat) surface. Total Runout controls flatness and perpendicularity to the datum axis, if used on a planar (flat) surface.

Are your Micocronic™ collets interchangeable with with any other companies collets?

Our collets are uniquing make to only fit with our cartridge. However, our cartridges fit into TF20, TF25, 5C, TF37 and 16C spindles which provide a much higher level of accuracy than standard collets.

Our collets are uniquing make to only fit with our cartridge. However, our cartridges fit into TF20, TF25, 5C, TF37 and 16C spindles which provide a much higher level of accuracy than standard collets.

|

How can you claim ".0001" to .00015" (3 microns) concentricity, and guaranteed to be within 0.0002" (5 microns) in production use" if our sub spindle sleeve on our CNC does not hold that concentricity? How can I be sure that I can reliably get 5 microns concentricity?

Many customers have found that our cartridges can be used as a gage to measure the TIR in the ir spindle. Often times the easiest corrective action is to remove the spindle sleeve and clean it and recheck it with our cartrrdige. Our cartridge is accurate enough to serve as a gage. Sometimes it may lead to replacing the sleeve or bearings. |

Why are you extending the nosepiece of the cartrdige out beyond the spindle nose? Doesn't that reduce concentricity and rigiditiy?

The patented cartridge body is a one piece solid precision ground unit. Our nosepiece extends out just beyond the spindle to tool clearance but because of the very tightly ground tolerance.

The patented cartridge body is a one piece solid precision ground unit. Our nosepiece extends out just beyond the spindle to tool clearance but because of the very tightly ground tolerance.

Why is the Micoroconic better than an Emergency Collet?

Emergency can only be used on a single part set up on a single machine. Our collets are not only interchangeable between machines but also permit repeatability of clamping pressure on each and every machine

The materail they are made of is tytpcially soft. Our precision collets are hardened and then precision ground which prevents chips from damaging the collet and part. Emergency collets has a very short life when compared to our Microconic™ collets. Finally the set up times for our micorconic collets have reduced set up nd changer over time up to 95% of the time requires to set up an emergency collet.

Emergency can only be used on a single part set up on a single machine. Our collets are not only interchangeable between machines but also permit repeatability of clamping pressure on each and every machine

The materail they are made of is tytpcially soft. Our precision collets are hardened and then precision ground which prevents chips from damaging the collet and part. Emergency collets has a very short life when compared to our Microconic™ collets. Finally the set up times for our micorconic collets have reduced set up nd changer over time up to 95% of the time requires to set up an emergency collet.

What About Very Small Diameters?

Increasingly, shops running Swiss are trying to run these machines lights out as much as practical. Ground stock, tool monitoring and redundant tooling are some of the schemes that make this possible. Worry-free workholding is another consideration that shops should consider for untended machining, especially when using small-diameter raw stock.

In Swiss applications, very small diameters in bar and coil can cause feed problems. These small-diameter bars lack the stiffness to feed in-line and can deflect as the bar feeder pusher moves it into the headstock and guide bushing. Often, the diameter of the bar or coil is smaller than the slots in the collet or guide bushing, making it difficult to keep the stock on center as it is fed. [READ MORE]

Increasingly, shops running Swiss are trying to run these machines lights out as much as practical. Ground stock, tool monitoring and redundant tooling are some of the schemes that make this possible. Worry-free workholding is another consideration that shops should consider for untended machining, especially when using small-diameter raw stock.

In Swiss applications, very small diameters in bar and coil can cause feed problems. These small-diameter bars lack the stiffness to feed in-line and can deflect as the bar feeder pusher moves it into the headstock and guide bushing. Often, the diameter of the bar or coil is smaller than the slots in the collet or guide bushing, making it difficult to keep the stock on center as it is fed. [READ MORE]

Can we get collet pad lengths of .050" on the over grip collets?

Yes

Yes

Is this system a dead stop system? (meaning once we set the pick off distance once, will it pick off in the same spot every time?

Yes, the Microconic system will always stop in the exact location for length. It's "Dead length"

Yes, the Microconic system will always stop in the exact location for length. It's "Dead length"

Is there a minimum land width for your overgrip collets? If so does it vary by size?

It depends on the size of the overgrip. The smaller sizes can be reduce to 0 land area (unlimited). The larger sizes can be reduced significantly, but we have to review on a case-by-case basis. If we can reduce it enough from the front nose, it is possible to remove some from the inside, but is more difficult and may incur additional processing costs.

It depends on the size of the overgrip. The smaller sizes can be reduce to 0 land area (unlimited). The larger sizes can be reduced significantly, but we have to review on a case-by-case basis. If we can reduce it enough from the front nose, it is possible to remove some from the inside, but is more difficult and may incur additional processing costs.

When reducing the land width on an overripe collet is the material removed from the face of the collet or the back of the face?

Yes, the length will be taken from the front or nose face.

Yes, the length will be taken from the front or nose face.

Are two day lead times standard turn around for off the shelf products? How much more lead time will it take to get our custom collets if they can make what we need?

EVERYTHING ships in 2 days, including "standard specials" like overgrip with shortened land length. Some specials like counterbore or tapered collets take longer, usually within a week. We have limits to what we will do with specials -- evaluated on a case by case basis.

Our production system is structured from the ground up to meet the 2 day shipping policy.

EVERYTHING ships in 2 days, including "standard specials" like overgrip with shortened land length. Some specials like counterbore or tapered collets take longer, usually within a week. We have limits to what we will do with specials -- evaluated on a case by case basis.

Our production system is structured from the ground up to meet the 2 day shipping policy.

Can I buy directly from you?

We only sell through authorized resellers of our products. For more details please see our Sales Policy.

We only sell through authorized resellers of our products. For more details please see our Sales Policy.

How can I become an authorized re-seller?

Please call 760.732.1422 and speak to a Masa Tool customer service representative for consideration to be a Microconic™ distributor.

Please call 760.732.1422 and speak to a Masa Tool customer service representative for consideration to be a Microconic™ distributor.