|

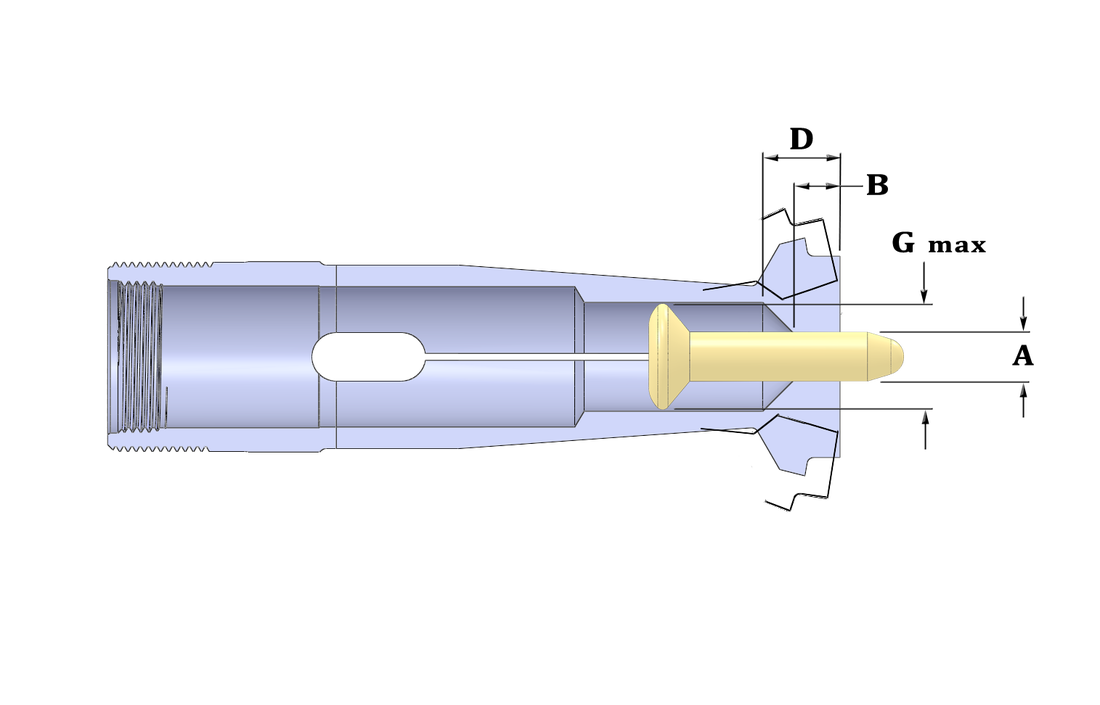

Matt Saccomanno at Masa Tool describes how the Microconic workholding system functions without the need for an extended nose. He says the accuracy and rigidity greatly improve with the diameter clearance already built into the system.

0 Comments

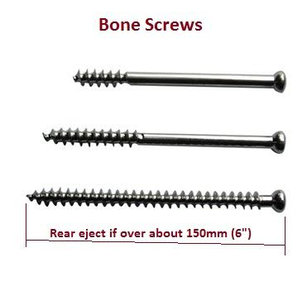

OCEANSIDE, CA. - At IMTS 2022 we where visited by the great folks at GIE Media, Inc. who publish Today's Medical Developments, Aerospace Manufacturing and Design and Today’s eMobility. They asked Matt Saccomanno, the inventor of the Microconic system to give them an on-camera overview of our products and how they work. As you probably already know, Masa’s Microconic Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface in your Swiss type CNC screw machine. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of shifting part operations from the main to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. At IMTS 2022, we expanded our Microconic line of swiss type CNC machine workholding. The new push type F15M5 and F16M5 cartridges replace the standard TF15 and TF16 collets in your CNC spindle. This enables you to use the newly introduced Microconic UM5 collet series with the Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. The off-the-shelf Microconic system concentricity of the cartridge and collet system combination is guaranteed to be within 5µm (0.0002") in production use. Both the F15M5 and F16M5 cartridges are a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F15M5 cartridge is compatible with spindles that accept Schaublin F15 76-580, E120, Southwick & Meister TF15 and Hardinge TF15 / 4607 collets, while the F16M5 cartridge is compatible with spindles that accept Schaublin F16 76-1076, E1212, Southwick & Meister TF16 and Hardinge TF16 / 4609 collets. Along with the new smaller cartridges comes a comprehensive series of UM5 collets that are ideally suited for small diameter part sizes ranging from 0.2mm/.008" to 5.5mm/.217" in diameter. These are available in regular type UM5 collets as well as all three types of Microconic's T, V and W type Over-Grip collets. Masa Tool offers the most unique variety of over-grip collets in the industry. And yes, if you listened closely to the video, you heard correctly, Matt spilled the beans on the new product that we'll be releasing next: The F13M5 Cartridge. And after that, we're going to heed that advise of "go big or go home. Yea, that was a spoiler alert.  The things that seems to excite Swiss machinists the most is our Micrograd™ wrench. The Micrograd Dial Wrenches provides a method of precisely setting clamping pressure on both the regular Microconic collets and on all series of Microconic over-grip collets. It can be adjusted in an infinite number of increments between the metric graduations of 0,02mm and inch/imperial graduations of .001" With the Micrograd Dial you can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel". The standard Microguide EGS is made of brass. Masa Tool has expanded the standard offer of Microguide EGS to include a selection of both Plastic and Stainless Steel versions. A critical aspect to using over-grip collets is to make sure the part is ejected reliably when it is completed being machined. Due to the wide opening of the over-grip collets, parts can get jammed in the collet slot. As a result, the collet will be damaged or break when it is closed. Every Microconic over-grip collet is supplied with a blank Microguide EGS ejection guide sleeve that you can drill to size to fit your specific part to enable the finished part to be ejected consistently without damage to the over-grip collet. The EGS is meant to be drilled through with a loose-fitting hole that will support and help guide the workpiece as it is ejected from the collet. Users can customize the Microguide EGS to match their specific workpiece and method of ejection. EGS10-XX, Ejection Guide Sleeves - Currently available in all materials & sizes below: EGS10-01 for UM10W-(ALL) 360 Brass EGS10-02 for UM10V-(ALL) 360 Brass EGS10-03 for UM10W-(ALL) 303 Stainless Steel EGS10-04 for UM10V-(ALL) 303 Stainless Steel EGS10-05 for UM10W-(ALL) Acetal (Delrin) EGS10-06 for UM10V-(ALL) Acetal (Delrin) EGS10-07 for UM10T-20 to -240 360 Brass EGS10-08 for UM10T-245 to -325 360 Brass EGS10-09 for UM10T-330 to -420 360 Brass EGS10-10 for UM10T-425 to -530 360 Brass EGS10-11 for UM10T-535 to -635 360 Brass EGS10-12 for UM10-(ALL) 360 Brass (15mm length rear extension)  We also have a special type of guide sleeve blank designed for very long parts like this, which extends out the back end of the collet about 1/2" further to give some support. They are our part number EGS10-12. Due to the extreme opening capability of our overgrip collets , workpiece ejection must be very reliable to prevent a part from becoming stuck in the slots of the collet. Therefore we have developed the Microguide™ ejection guide sleeve to prevent parts from falling inside the collet instead of ejecting into the part catcher.

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed