|

The standard Microconic collets will help with bone screws and other bone implants by allowing a firm grip on the threaded exterior without causing damage, and yet holding it so much more rigidly that they will be able to do heavy operations in the sub spindle. This includes operations like blind hole broaching. Set ups are quicker and more repeatable with Microconic. With the Microgram Dial Wrench You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

0 Comments

We have just released the NEW 2018-2019 Masa Tool Catalog! Our first batch of new catalogs is shipping directly to our IMTS booth in Chicago for release, but you can download your own copy right here!

OCEANSIDE, CA - Masa Tool has just released the newest product in the Microconic line of cartridges for swiss machine workholding. The NEW push type F201M10 Cartridge replaces the Tornos F20-201 collet in your CNC spindle. This enables you to use our Microconic collets to achieve concentricity guaranteed to be within 5µm (0.0002") in production use. The F201M10 Cartridge is a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F201M10 Cartridge is compatible with spindles that accept F20-201 collets including DIN 136E, Meister Swiss 136E, Schaublin F20 (76-201), Southwick & Meister F20-201, KEB (MasWerks) MC20-201, Hardinge F20-201 / 4709 collets. Masa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of moving part operations to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. F201M10 Cartridge Features

Set ups are quicker and more repeatable with Microconic™. You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

How to use the Micrograd™ Face Dial Wrench

For a complete set of instructions please see our installation procedures for more details on how to set up and replicate your clamping pressure on every machine in your shop.

This article originally appeared in the April 2017 issue of Today's Medical Developments. It was the cover story entitled: "Micro-Precision Machining" by Elizabeth Modic Microconic’s cartridge is made of exotic high-chromium tool steel, triple tempered and cryogenically treated to provide stable construction. All functional seating surfaces are ground with extreme precision on a one-piece, ultra-rigid body structure. “The cartridge can be used as a calibration gage to verify the machine spindle accuracy,” Co-owner Chip Prescott notes. Microconic collets are finished to exacting standards with a five-step grinding process that removes the effect of heat-treat warpage. Also, the proprietary Microconic form of the closure surfaces is inherently more accurate than traditional collets, providing for a greater full-accuracy working range. Cartridges are available to fit in push-type dead-length collet closers and also draw-type closers: F20M10 (for TF20 collet replacement), F25M10 (for TF25 collet replacement), and 5CM10 (for 5C collet replacement). All of these cartridges use the same Microconic UM10 collets, with more cartridge sizes in development to be released soon. We got a very unexpected present in the mail this past week! We where very excited to learn that our Microconic workholding system for small diameter part machining was featured in the Rapid Traverse section of the June 2017 issue of Modern Machine Shop!!! We've got pictures of the article below in case you don't currently subscribe to Modern Machine Shop. You can also download a PDF copy of the entire June issue below in the link. It starts on Page 25 of the PDF download. If you have the print edition it's on Page 22, or you can just read thought the screen shots below. We want to really extend a very big THANK YOU to Matt Danforth at Modern Machine Shop who wrote this article. Matt really did an awful lot of work learning about the various features of our system. We know there where many many hours that he spent to develop this story just from the sheer number of follow up questions and conversations. We really have an awful lot of respect for the entire MMS team and the effort they put into getting their story's "just right".

This article originally appeared in the April 2017 issue of Today's Medical Developments. It was the cover story entitled: "Micro-Precision Machining" Matt Saccomanno’s Microconic collet-type workholder for small part machining was inspired by his experience in a Swiss screw-machine job shop. By Elizabeth Modic

The Microconic system will be able to do things that are impossible |

|||||||||||||||||||||||||||||||||

| Our regular MicroconicTM collets help reduce cycle time by allowing a rm grip on the workpiece without causing damage, and yet holding it much more rigidly than any other collet on the market. You’ll be able to do heavy machining operations in the sub spindle, such as blind hole broaching, that would not have even considered in the past. Now you can switch ops from main to sub! Set ups are quicker and more repeatable with Microconic. You can document the micrometer-adjust collet closure in your set up plan using our Micrograd Face Dial Wrench and it’s going to repeat to the same clamping pressure each and every time, regardless of operator skill and without relying on “feel”. You can calibrate your spindle accuracy with the MicroconicTM cartridge by using it as a precision cylinder gauge. When that is good, EVERY Microconic collet will run within .0002” TIR: There’s no ddling and swapping collet after collet looking for a “good” one. Set ups go smoothly and predictably. | The Microconic collets fit into our cartridge to hold the workpiece with great precision and rigidity. Unlike traditional extended nose collets our unique design and closing action is inherently more accurate and consistent. The clamping force is directly over the workpiece at the end of the collet. The origin of the word “Microconic”, alludes to the precise way in which the collet closing taper is formed to cancel the effects of heat treat warp and grind tolerances. As a result, it provides industry- best concentricity every time. |

Download or View the 2017 Masa Tool Microconic Catalog:

Blog: 2/17/2017

by MATT DANFORD

Associate Editor, Modern Machine Shop

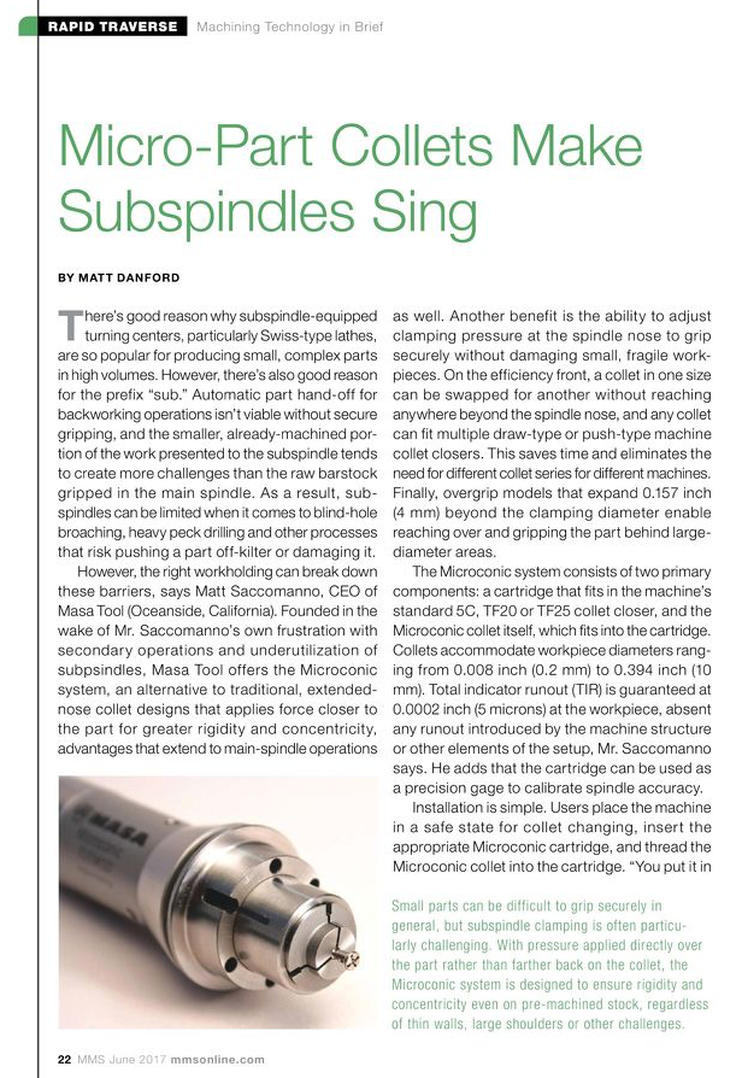

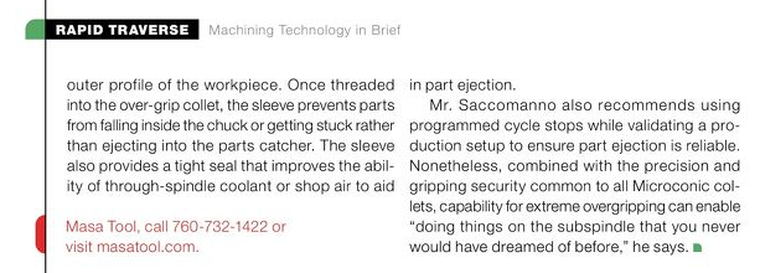

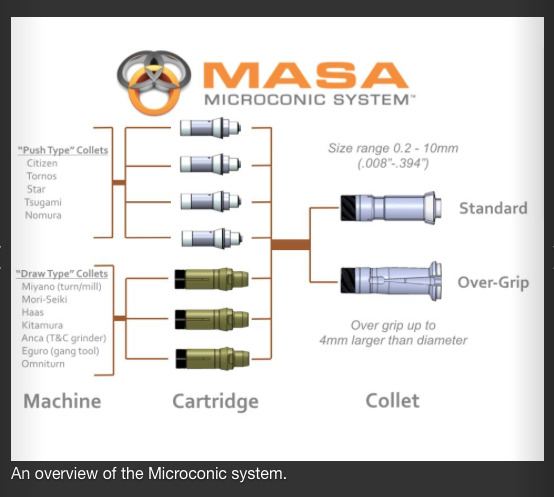

| However, the right workholding can break down these barriers, says Matt Saccomanno, CEO of Masa Tool (Oceanside, California). Founded in the wake of Mr. Saccomanno’s own frustration with secondary operations and underutilization of subpsindles, Masa Tool offers the Microconic system, an alternative to traditional, extended-nose collet designs that applies force closer to the part for greater rigidity and concentricity—advantages that extend to main-spindle operations as well. Another benefit is the ability to adjust clamping pressure at the spindle nose to grip securely without damaging small, fragile workpieces. On the efficiency front, a collet in one size can be swapped for another without reaching anywhere beyond the spindle nose, and any collet can fit multiple draw-type or push-type machine collet closers. This saves time and eliminates the need for different collet series for different machines. |

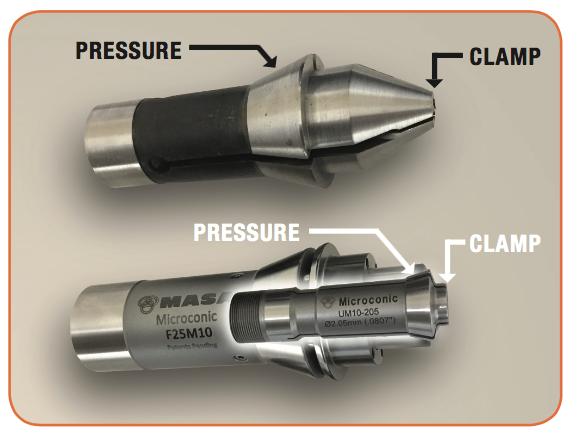

| The Microconic system consists of two primary components: a cartridge that fits in the machine’s standard 5C, TF20 or TF25 collet closer, and the Microconic collet itself, which fits into the cartridge. Collets accommodate workpiece diameters ranging from 0.008 inch (0.2 mm) to 0.394 inch (10 mm). Total indicator runout (TIR) is guaranteed at 0.0002 inch (5 microns) at the workpiece, absent any runout introduced by the machine structure or other elements of the setup, Mr. Saccomanno says. He adds that the cartridge can be used as a precision gage to calibrate spindle accuracy. |

| There’s no “feel” involved in tightening the collet, he says. That’s a task accomplished with the company’s Micrograd wrench, which features micrometer graduations of 0.001 inch (0.02 mm) to aid users in dialing in the perfect closure on either a workpiece or a gage pin of the same size. This configuration relegates the machine’s own clamping mechanism to the role of an actuator that triggers the opening or closing of the collet. As such, he advises keeping the machine’s own function at a medium force setting and allowing the Microconic cartridge to control the actual chucking force. Machined from a single piece of hardened steel, the cartridge preserves the dead-length operation of “push-type” collet systems (that is, the collet itself doesn’t move in or out as the machine cartridge actuates the chuck). |

| He credits much of that precision to the fact that clamping force is applied directly over the workpiece, a contrast with traditional extended-nose designs that apply force farther back. He also credits the manufacturing process. Tapering collet jaws to interface with the machine is nothing unusual. However, Masa Tool employs a proprietary, five-step grinding process that leaves each jaw with a particularly precise conical shape (hence the name “Microconic”) that forms a particularly tight fit. More specifically, a “slight crown” ensures that the contact point is always centered, he explains, citing the pattern of wear marks on well-used collets as evidence. |

| Gripping wasn’t the company’s only focus when designing the Micronic system. Reliable part ejection is also critical, Mr. Saccomanno says, particularly with overgrip collets that offer such a wide gripping range. That’s why overgrip models ship with a Microject, a brass ejection guide sleeve that can be machined to mirror the outer profile of the workpiece. Once threaded into the over-grip collet, the sleeve prevents parts from falling inside the chuck or getting stuck rather than ejecting into the parts catcher. The sleeve also provides a tight seal that improves the ability of through-spindle coolant or shop air to aid in part ejection. |

We discussed that many many people had just given up on trying to find a solution for balancing out production between the main spindle and the sub-spindle years and years ago. We where even more excited than most of the people that stopped by our booth to learn that we had indeed invented something that fixes the problem!

|

A big thank you to the folks at AMT and IMTStv who interviewed us at the show for the big screen!!

"If you manufacture small parts, you have to see this microconic system, it's no ordinary collet! Check out what we found in the west hall at Microconic by Masa Tool's booth W-2232!" Watch more videos at IMTS.com/IMTSTV |

|

Author

Here you will find the latest press releases, news coverage and technical information about our Microconic™ system

Archives

February 2023

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

January 2022

October 2021

May 2021

July 2020

March 2020

February 2020

December 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

June 2017

May 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

March 2016

February 2016

January 2016

December 2015

November 2015

October 2015

September 2015

August 2015

July 2015

May 2015

April 2015

August 2014

May 2014

March 2014

July 1999

Categories

All

5C Cartridge

5C Collet

Advanced Manufacturing

Advertisement

Agent Profile

AMTS

APT Machine Tools

Avinger

Bell Mouthing

Bone Screws

Case Study

Catalog

CEO CFO

Chip Wrapping

Cincom

Cincom L12

Cincom L20

Cincom M16

Cincom M32

CNC West

Collet

Concentricity

Dental Implants

Dragan Marjanovic

Dunner SA

Eastec

Ejection Guide Sleeve

Emergency Collet

F13M5

F15M5

F16M5

F201M10

F20M10

F37M10

Floyd Automatic

Ganesh

High Tech Industrial

IMTS

ISwiss

Jones Marketing

Lane 4

Machinery Trade International

Magazine Article

Mann Sales

Marubeni Citizen

Material: 6Al4V

MAV Innovations

Metal Cutting Corp

Microconic

Micrograd Wrench

Microguide Sleeve

Micromachining

Micro-Matics

Modern Machine Shop

Morris South

NETC

Next Generation Tooling

Oceanside Facility

Oktoberfest

Open House

Overgrip Collet

Part: Counterbore Drills

Part: Dental Drills

Part: Dental Impant

Part: Medical Device

Part: Surgical Drills

Part: Surgical Taps

PMTS

Press Release

Production Machining

Productivity Inc.

Ram Sales & Marketing

Schlenker

SIAMS

South Tec

South- Tec

Star CNC

Star SR20

STEM

Tech Tip

TF15

TF16

TF20

TF25

TF37

Todays Medical Developments

Tool Marketing Service

Trade Show

Trade Shows

Tsugami

UM10

UM10T

UM10W

UM5

UM5T

UM5V

UM5W

Videos

Workpiece Deflection

RSS Feed

RSS Feed