About Masa Tool

With deep roots in the Swiss-type screw machine industry, Masa Tool Inc. was founded in Oceanside California with the mission of bringing the Microconic System to the world. This revolutionary workholding system consists of the Microconic “cartridge” and “collet”. It was invented to solve the problems created by traditional long nose collets commonly used in the sub-spindle of screw machines for over 100 years.

As screw machines evolved from mechanical cams in the late 1900’s to today’s CNC controls, the complexity of parts being made increased dramatically. Making these modern micro precision parts complete on the machine without additional secondary operations became critical to remain competitive. Using the machine’s sub-spindle to complete the part is a must. As the demands for precision and complexity increase, the traditional long-nose collet has many limitations that can frustrate the machinist trying to get the most out of the machine.

We created the Microconic system to overcome these limitations of conventional collets. The result is superior rigidity, accuracy, over-grip capability, clamping force control, and long-run stability. We at Masa built our company from the ground up to ensure that everything in our catalog is available to ship within 2 days. Every size, every type. We currently offer any size from 0.2mm – 10mm diameter (.008” - .394”).

As screw machines evolved from mechanical cams in the late 1900’s to today’s CNC controls, the complexity of parts being made increased dramatically. Making these modern micro precision parts complete on the machine without additional secondary operations became critical to remain competitive. Using the machine’s sub-spindle to complete the part is a must. As the demands for precision and complexity increase, the traditional long-nose collet has many limitations that can frustrate the machinist trying to get the most out of the machine.

We created the Microconic system to overcome these limitations of conventional collets. The result is superior rigidity, accuracy, over-grip capability, clamping force control, and long-run stability. We at Masa built our company from the ground up to ensure that everything in our catalog is available to ship within 2 days. Every size, every type. We currently offer any size from 0.2mm – 10mm diameter (.008” - .394”).

|

MissionMasa Tool exists to revolutionize micro-precision machining for the benefit of humanity, and for the joy and profit of our employees, customers, and shareholders.

|

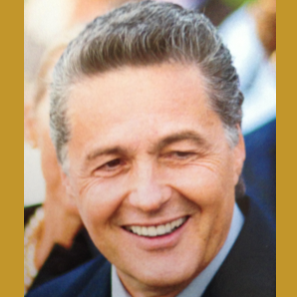

According to Matt Saccomanno, CEO of Masa Machine Tool Accessories, he conceived the Microconic™ cartridge system in utter frustration while trying to set up machinery in his own shop for secondary operations on small parts.

|

"This setup would be so easy if I didn't have to deal with that stupid fixture," he recalls thinking at the time.

The only purpose for the fixture was to allow the endmill to reach down to the part without hitting the 5C collet nose with the spindle. "Well, I finally got the fixture to work that day, but more important, an idea was born so I wouldn't have to deal with that problem again," he says. "The idea eventually became the Masa small parts cartridge and collet. Then the uses for it went far beyond my original ideas. Soon they were all over the shop—in the tool grinding room, on CNC lathes, CNC mills, as well as in 'second op.' |

|

What is Microconic®?The word "Microconic" comes from the revolutionary design and sophisticated grinding techniques of our collets.

The Microconic system provides extreme accuracy, high rigidity, and previously unattainable tolerances for workpiece size variance. Each finger of the collet has a separate conical surface that acts to apply the gripping force with superb accuracy. |