|

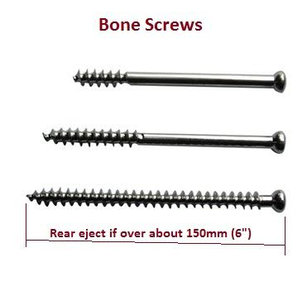

The standard Microconic collets will help with bone screws and other bone implants by allowing a firm grip on the threaded exterior without causing damage, and yet holding it so much more rigidly that they will be able to do heavy operations in the sub spindle. This includes operations like blind hole broaching. Set ups are quicker and more repeatable with Microconic. With the Microgram Dial Wrench You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

0 Comments

A Swiss CNC machine shop presented us with several problems related to long cycle times and poor tool life with a high-volume group of Dental Surgical Drills, Taps, and Counterbore Drills with standard ISO shank configuration.

Before Microconic: The Workholding ProblemsBefore implementing the Microconic solution there were a number of problems:

High precision long nose collet system for sliding-head Swiss-type CNC lathe/turning centers. Opens 4mm larger than clamping diameter! Super accurate, super rigid. Wiha: Family business with a high level of vertical integration Founded 80 years ago as a small company by Willi Hahn, Wiha Werkzeuge is now a global company with production sites in Vietnam, Poland, Germany and Switzerland. In the second generation, his son Wilfried Hahn, who is still part of the management team today, built up a global company network that is currently managed by the founder's grandson, Wilhelm Hahn. The Mönchweiler plant is the location for the company's VDE tools. The screwdrivers and bits that are manufactured here are usually coated with plastic to protect the user from electric shocks. According to Andreas Stengele, head of the Langdreher / Bits department at Wiha, the resulting very high demands on security and quality still justify production in the high-wage location of Germany. The plant, or the entire company, impresses with a high level of vertical integration. Even the hardening process and the surface treatment take place on site. Only the electroplating is done externally. Clamping technology specialist at the hand tool manufacturer In production at the Mönchweiler location, Wiha relies on a total of 13 Swiss-type lathes from various manufacturers. The Schlenker company, which is based in nearby Villingen-Schwenningen, has made special modifications to some of the Swiss-made lathe machines and, for example, modified the mounting of the counter spindle. The fine line of proper leadership Bits for screwdrivers are a core product in Mönchweiler: Wiha produced 1.1 million of these components in 2018 from low-alloy spring tool steel, mostly in batches of around 5,000. The raw material is provided in hexagonal bars, each three meters in length. During machining, very high concentricity and roundness requirements are placed on the parts. If this is not the case, the insulating plastic layer will be distributed unevenly during overmolding and the risk of breakdown when working with the screwing aid increases. Particularly in the area of guide bushes on Swiss-type lathes, it is difficult to meet the requirements in terms of both concentricity and roundness. According to Andreas Stengele, this is due to the diameter of the material used: “We work in the diameter range of three to four millimeters, but we use much larger machines. Because the smaller machines offer neither the necessary tool positions nor the necessary performance. ”The hexagonal bars are clamped with the main collet and guided through a guide bush. If it is too narrow, the material will bend when it is fed. However, if it is too loose, concentricity and roundness will suffer. “That's why it's always a fine line how I adjust the guide bushing,” says the expert. Conventional, adjustable guide bushes can be adjusted using a thread. Flexible guide bushes, on the other hand, such as those offered by Schlenker, adapt to the material. Eugen Belz, technical manager at Schlenker: “This is a pneumatic system that is controlled by the machine. There is a constant pressure on the guide bush, for example 2.5 bar. If the material becomes larger or smaller, the guide bush adapts to the changed conditions. " Reaching over for rear processing In order to further optimize the bit production process and save cycle times, Schlenker has equipped the Swiss-type lathes with the Masa tool. The overgrip collet from the Masa makes it possible to overgrip turned parts with a diameter difference of up to four millimeters, regardless of the available path of the machine. This means that the subspindle can be viewed as a fully-fledged spindle. Depending on the geometry of the workpiece to be machined and the possibilities of the machine, this can lead to enormous savings in cycle times. The Masa Tool Microconic systems consists of a base body and, in this case, an over-grip collet in T-design. The use of this collet makes sense if the diameter to be clamped is smaller than the diameter to be overcome. This enables a concentricity of 5 μm. The system is used in the subspindle and can be precisely set on the machine. For this purpose, Schlenker provided the Masa Tool MicroGrad setting ring, whereby the closure of the microconic collet can be adjusted in steps of 0.02 mm. This setting is then held by the base body. According to Andreas Stengele: “Normal collets are adjusted by feeling. With the Microconic system, I can define exactly how far you tighten it for the ideal tension." The closed system is made of spring steel and is very flexible. "We have been offering the system for over two years and have not yet seen a break," emphasizes Eugen Belz. Minimize cycle and changeover times Without the Microconic solution, processing would alternatively only be possible in two stages, which ties up more capacities and employees - because Wiha does not manufacture unmanned. “It's always about saving yourself the second or third step,” explains Daniel Schanne. The aim is to reduce lead times in order to get the product to the customer faster. In this way, more than a quarter of the cycle time could be saved in the small parts series. The family business has also organized its production in such a way that ideally only one bar diameter is machined on a sliding head lathe and therefore only the profile to be milled changes. Since the rear side remains the same and is spanned at the front, the machines do not have to be converted, which is time-consuming. "In order to mill the most varied of screw profiles, you only have to change the milling cutter," says Daniel Schanne with satisfaction. To view the original article click here.  The standard Microguide EGS is made of brass. Masa Tool has expanded the standard offer of Microguide EGS to include a selection of both Plastic and Stainless Steel versions. A critical aspect to using over-grip collets is to make sure the part is ejected reliably when it is completed being machined. Due to the wide opening of the over-grip collets, parts can get jammed in the collet slot. As a result, the collet will be damaged or break when it is closed. Every Microconic over-grip collet is supplied with a blank Microguide EGS ejection guide sleeve that you can drill to size to fit your specific part to enable the finished part to be ejected consistently without damage to the over-grip collet. The EGS is meant to be drilled through with a loose-fitting hole that will support and help guide the workpiece as it is ejected from the collet. Users can customize the Microguide EGS to match their specific workpiece and method of ejection. EGS10-XX, Ejection Guide Sleeves - Currently available in all materials & sizes below: EGS10-01 for UM10W-(ALL) 360 Brass EGS10-02 for UM10V-(ALL) 360 Brass EGS10-03 for UM10W-(ALL) 303 Stainless Steel EGS10-04 for UM10V-(ALL) 303 Stainless Steel EGS10-05 for UM10W-(ALL) Acetal (Delrin) EGS10-06 for UM10V-(ALL) Acetal (Delrin) EGS10-07 for UM10T-20 to -240 360 Brass EGS10-08 for UM10T-245 to -325 360 Brass EGS10-09 for UM10T-330 to -420 360 Brass EGS10-10 for UM10T-425 to -530 360 Brass EGS10-11 for UM10T-535 to -635 360 Brass EGS10-12 for UM10-(ALL) 360 Brass (15mm length rear extension)  We also have a special type of guide sleeve blank designed for very long parts like this, which extends out the back end of the collet about 1/2" further to give some support. They are our part number EGS10-12. OCEANSIDE, CA - Masa Tool has just released the newest product in the Microconic line of cartridges for swiss machine workholding. The NEW push type F201M10 Cartridge replaces the Tornos F20-201 collet in your CNC spindle. This enables you to use our Microconic collets to achieve concentricity guaranteed to be within 5µm (0.0002") in production use. The F201M10 Cartridge is a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F201M10 Cartridge is compatible with spindles that accept F20-201 collets including DIN 136E, Meister Swiss 136E, Schaublin F20 (76-201), Southwick & Meister F20-201, KEB (MasWerks) MC20-201, Hardinge F20-201 / 4709 collets. Masa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of moving part operations to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. F201M10 Cartridge Features

Set ups are quicker and more repeatable with Microconic™. You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

How to use the Micrograd™ Face Dial Wrench

For a complete set of instructions please see our installation procedures for more details on how to set up and replicate your clamping pressure on every machine in your shop.

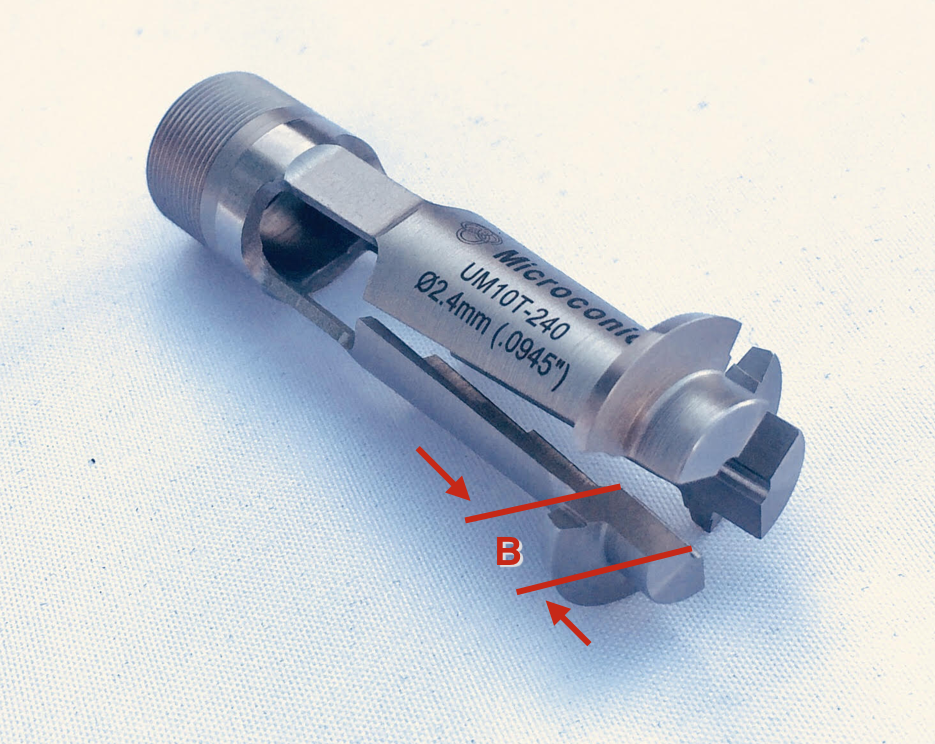

OCEANSIDE, CA. Masa Tool has expanded their line of Microconic over-grip collets to include a new style called a "T-type." The T-type over-grip collet has a longer gripping surface than the original W-type. We designed it specifically for longer parts such as bone screws with wide pitch threads.

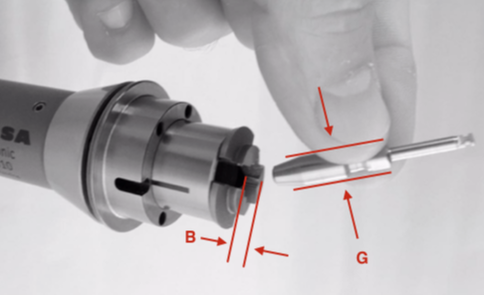

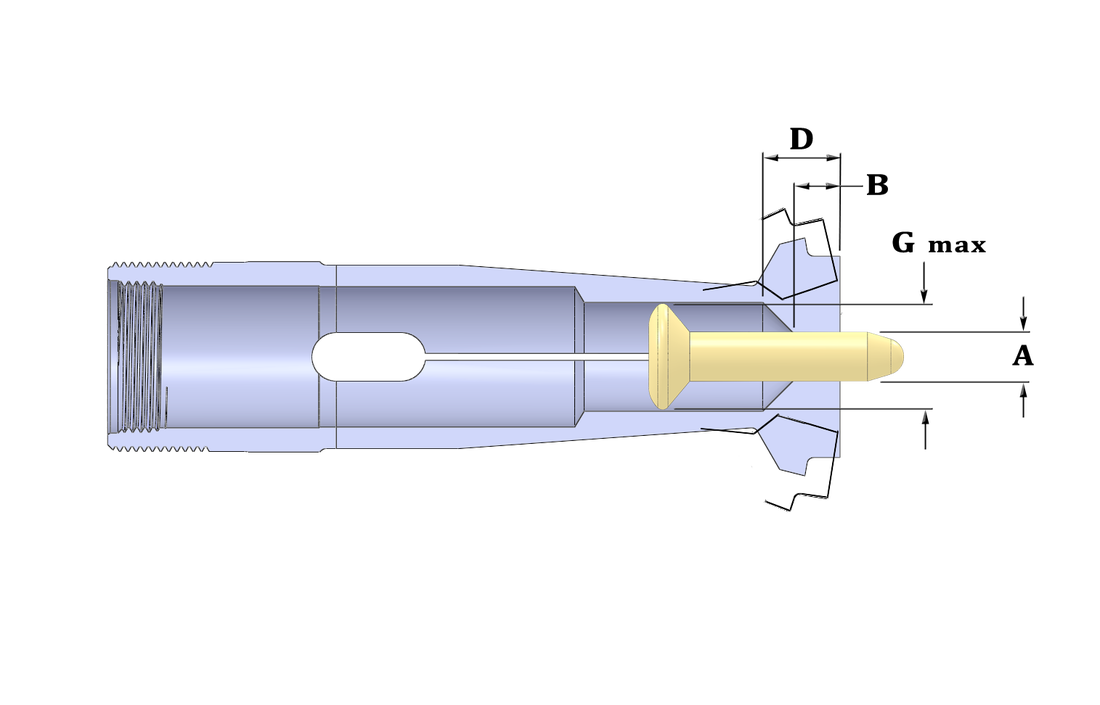

But, in some cases, with longer parts, the land width "B" needs to be longer to support the workpiece properly. Masa's new T-type collet provides the solution for longer workpiecesTypically with over-gripping applications, a shorter land length/clamping pad length/grip length is desired because of limited space available to hold the workpiece behind the enlarged head or flange that it is reaching over. That is what our original W-type collet was optimized for. However, with longer parts, with more surface area for clamping and gripping room, a longer land length is often preferred to provide more stability to support the longer length workpiece.

Microconic T-Type Over-grip Collet features

If you've tried other companies overgrip collets with poor results, Microconic over-grip collets will allow you to do things you might have thought impossible!

Due to the extreme opening capability of our overgrip collets , workpiece ejection must be very reliable to prevent a part from becoming stuck in the slots of the collet. Therefore we have developed the Microguide™ ejection guide sleeve to prevent parts from falling inside the collet instead of ejecting into the part catcher.

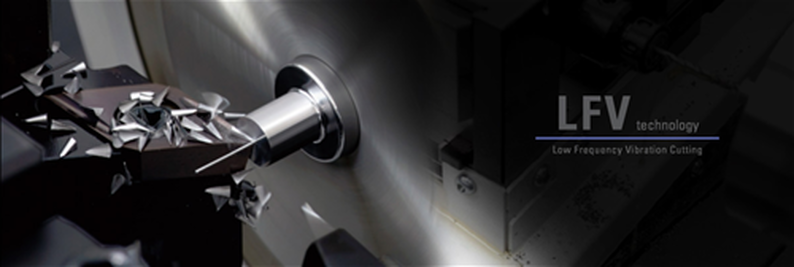

The Microconic Workholding system was featured at the Marubeni Citizen-Cincom of New England booth at the Eastec 2017 Machine Tool Show! Marubeni Citizen-Cincom is the exclusive New England distributor for Citizen Cincom Swiss style lathes and Miyano Multi Axis turning centers as well as ne of our premier distributors of the Micorconic Workholding system About the CINCOM L20 Low Frequency Vibration (LFV)State-of-the-art LFV is a widely applicable cutting technology designed to avoid the problem of spiraling chips, entanglement of chips and built-up edges. Benefits include increased cutting tool life, reduced heat generation and reduced power consumption.

The popular Citizen CINCOM L20 series sliding headstock lathes are now available with Low Frequency Vibration (LFV). This widely applicable cutting technology – able to handle a broad range of machining shapes and materials – is ideal for cutting difficult-to-cut materials. The state-of-the-art LFV suppresses various risks associated with these materials, such as entanglement of chips and built-up edges. Depending on the material being cut, a variety of problems can be caused by chips getting entangled with each other, including increased cutting resistance, scarring, changes in the texture of the machined surface, tool nose damage, and built-up edges due to cutting heat. In LFV cutting, “air cutting” time prevents the machining temperature from rising, which both prolongs tool lives and gives relief from various problems caused by chips. |

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed