|

The standard Microconic collets will help with bone screws and other bone implants by allowing a firm grip on the threaded exterior without causing damage, and yet holding it so much more rigidly that they will be able to do heavy operations in the sub spindle. This includes operations like blind hole broaching. Set ups are quicker and more repeatable with Microconic. With the Microgram Dial Wrench You can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel".

0 Comments

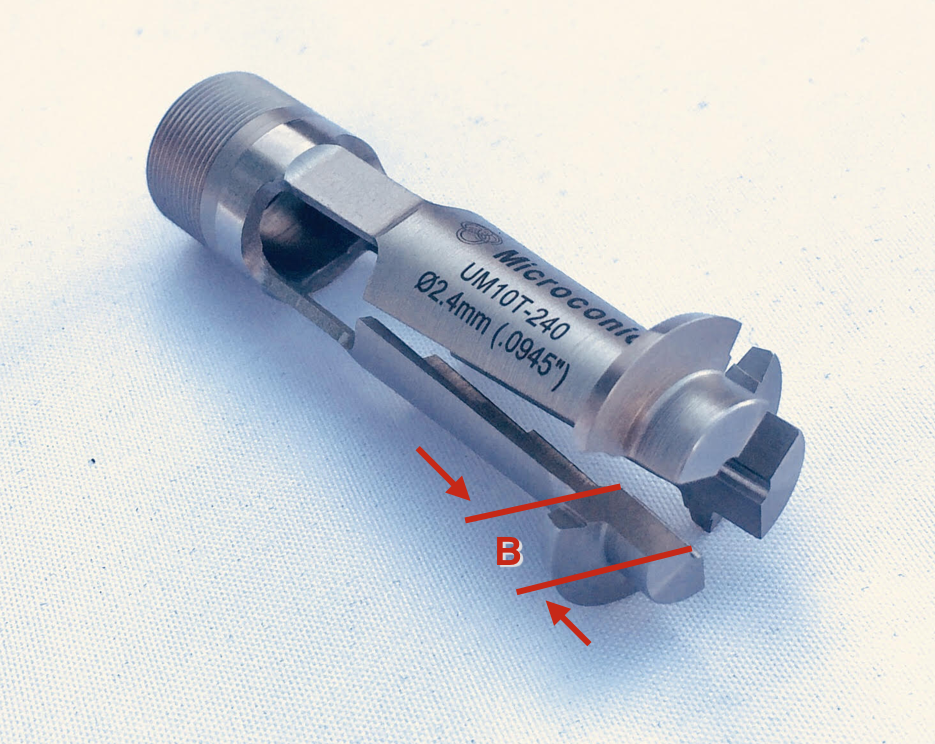

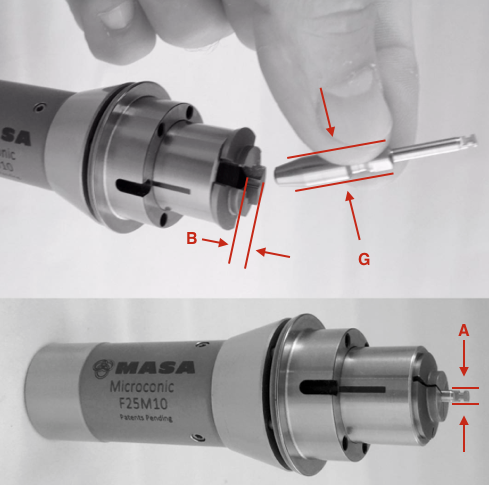

OCEANSIDE, CA. Masa Tool has expanded their line of Microconic over-grip collets to include a new style called a "T-type." The T-type over-grip collet has a longer gripping surface than the original W-type. We designed it specifically for longer parts such as bone screws with wide pitch threads.

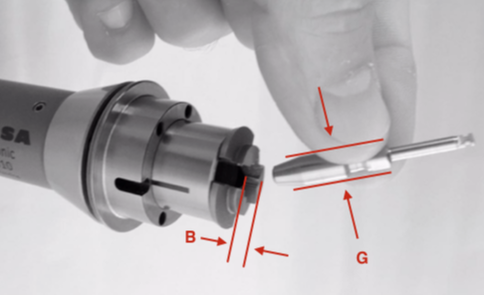

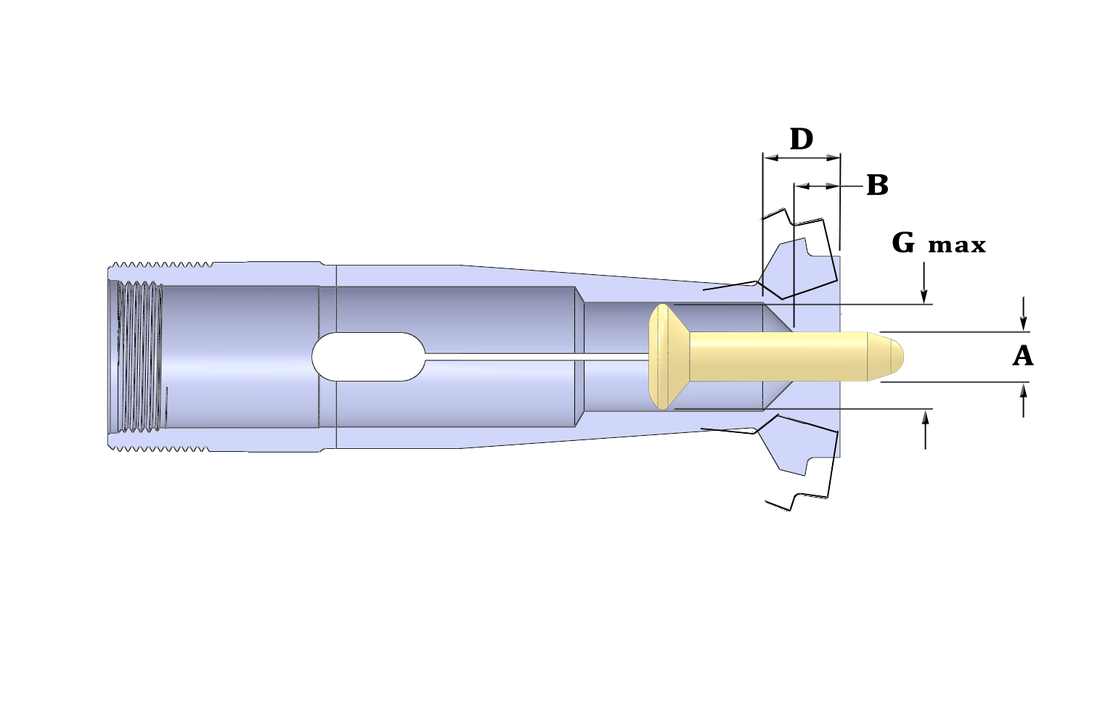

But, in some cases, with longer parts, the land width "B" needs to be longer to support the workpiece properly. Masa's new T-type collet provides the solution for longer workpiecesTypically with over-gripping applications, a shorter land length/clamping pad length/grip length is desired because of limited space available to hold the workpiece behind the enlarged head or flange that it is reaching over. That is what our original W-type collet was optimized for. However, with longer parts, with more surface area for clamping and gripping room, a longer land length is often preferred to provide more stability to support the longer length workpiece.

Microconic T-Type Over-grip Collet features

If you've tried other companies overgrip collets with poor results, Microconic over-grip collets will allow you to do things you might have thought impossible!

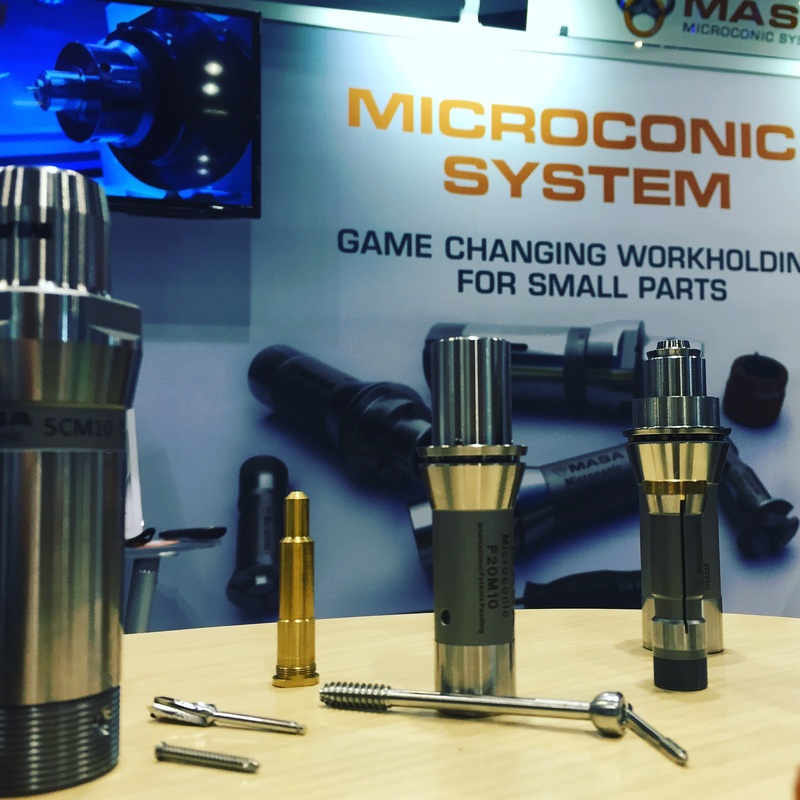

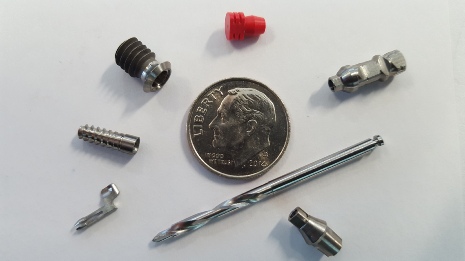

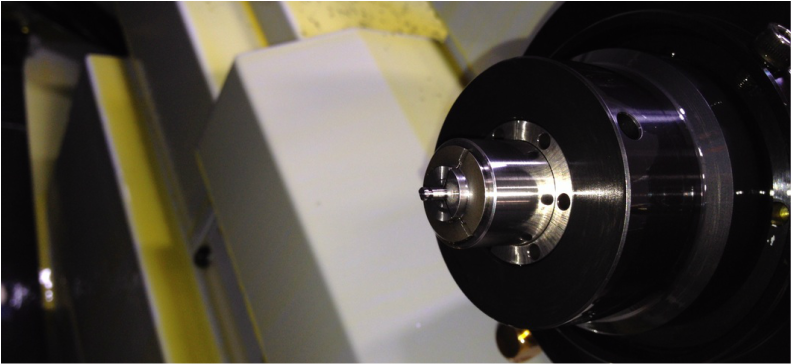

Matt Saccomanno, the inventor of the Microconic Workholding system discussed how it works at IMTS 2016. Masa Tool has developed the Microconic™ system specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck. The system consists of two major components: The Microconic™ cartridge, which fits into your CNC machine spindle replacing the standard 5C, TF20 or TF25 collets, and the Microconic™ collet, which fits in the Microconic™ cartridge. The Microconic™ system has unsurpassed concentricity: Our manufacturing tolerance is 3µm (.0001") and we guarantee our cartridges to be within 5µm (0.0002") in production use in your machine. The Microconic™ system works with either draw-type or push-type standard collet systems that are in any machine. The Over-grip collet capabilities of Masa Microconic™ System, introduces a whole new world of time saving opportunities awaiting. Our Overgrip Collets open up to 4mm (0.157") diameter larger than the clamping diameter.

Our first IMTS show was a tremendous success! We got to meet many many new customers and where very pleasantly surprised by all the industry media people who stopped by to visit us at the show. We had an awful lot of people comment on the "Game Changing Workholding for Small Parts" by asking us "What's so game changing?" After they learned about the entire Microconic system we often heard them say "Wow! This is REALLY a game changer!!"

On Thursday, Harry Moser from the Reshoring Initiative visited us and we talked about how our products where developed right from our experience on the shop and because of the machining that is done locally in the Oceanside area. The video was posted live on our Facebook Page and you can find right here down below on the left.

Be sure to keep an eye our for some articles in some pretty big name magazines in the next few months. We're now on the look out for some application stories for them based upon the success you've had with our product. If you have a story to tell us be sure to leave it in the comments below or contact us so we can get all the details!

"Every time the collet would chuck on the parts with chip wrap, it would leave an impression in the collet. Sometimes the chip would stay lodged in that impression and the parts run from that point on are scrapped due to the chip impressions on the part and once noticed, the collet would need to be replaced."

Masa Tool has developed the Microconic™ system specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck. The system consists of two major components: The Microconic™ cartridge, which fits into your CNC machine spindle replacing the standard 5C, 16C, TF15, Tf16 TF20 , TF25 or TF37 collets, and the Microconic™ collet, which fits in the Microconic™ cartridge. Part of the standard offering of Micrconic™ collets is the UM10W Over-grip series. The UM10W over-grip series is offered in the coverage range from Ø0.5mm - 7.2mm diameter (Ø0.020" - 0.283").

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed