|

Matt Saccomanno at Masa Tool describes how the Microconic workholding system functions without the need for an extended nose. He says the accuracy and rigidity greatly improve with the diameter clearance already built into the system.

0 Comments

OCEANSIDE, CA. - At IMTS 2022 we where visited by the great folks at GIE Media, Inc. who publish Today's Medical Developments, Aerospace Manufacturing and Design and Today’s eMobility. They asked Matt Saccomanno, the inventor of the Microconic system to give them an on-camera overview of our products and how they work. As you probably already know, Masa’s Microconic Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface in your Swiss type CNC screw machine. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of shifting part operations from the main to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. At IMTS 2022, we expanded our Microconic line of swiss type CNC machine workholding. The new push type F15M5 and F16M5 cartridges replace the standard TF15 and TF16 collets in your CNC spindle. This enables you to use the newly introduced Microconic UM5 collet series with the Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. The off-the-shelf Microconic system concentricity of the cartridge and collet system combination is guaranteed to be within 5µm (0.0002") in production use. Both the F15M5 and F16M5 cartridges are a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F15M5 cartridge is compatible with spindles that accept Schaublin F15 76-580, E120, Southwick & Meister TF15 and Hardinge TF15 / 4607 collets, while the F16M5 cartridge is compatible with spindles that accept Schaublin F16 76-1076, E1212, Southwick & Meister TF16 and Hardinge TF16 / 4609 collets. Along with the new smaller cartridges comes a comprehensive series of UM5 collets that are ideally suited for small diameter part sizes ranging from 0.2mm/.008" to 5.5mm/.217" in diameter. These are available in regular type UM5 collets as well as all three types of Microconic's T, V and W type Over-Grip collets. Masa Tool offers the most unique variety of over-grip collets in the industry. And yes, if you listened closely to the video, you heard correctly, Matt spilled the beans on the new product that we'll be releasing next: The F13M5 Cartridge. And after that, we're going to heed that advise of "go big or go home. Yea, that was a spoiler alert.  The things that seems to excite Swiss machinists the most is our Micrograd™ wrench. The Micrograd Dial Wrenches provides a method of precisely setting clamping pressure on both the regular Microconic collets and on all series of Microconic over-grip collets. It can be adjusted in an infinite number of increments between the metric graduations of 0,02mm and inch/imperial graduations of .001" With the Micrograd Dial you can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel". FOR IMMEDIATE RELEASE  Masa Tool's NEW products being introduced at IMTS 2022: The F15M5 & F16M5 cartridges and accompanying NEW UM5 collet series which includes over-grip collets and Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. CLICK THIS IMAGE TO ADD MASA TOOL'S IMTS BOOTH TO YOUR SHOW PLANNER OCEANSIDE, CA - Masa Tool has expanded their Microconic line of swiss machine workholding. The new push type F15M5 and F16M5 cartridges replace the standard TF15 and TF16 collets in your CNC spindle. This enables you to use the newly introduced Microconic UM5 collet series with the Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure. The off-the-shelf Microconic system concentricity of the cartridge and collet system combination is guaranteed to be within 5µm (0.0002") in production use. F15M5 and F16M5 CartridgesBoth the F15M5 and F16M5 cartridges are a micro-workholding system for use in high precision, small diameter CNC turning applications which enables you to move more work to the sub spindle operations and reduce cycle time. The F15M5 cartridge is compatible with spindles that accept Schaublin F15 76-580, E120, Southwick & Meister TF15 and Hardinge TF15 / 4607 collets, while the F16M5 cartridge is compatible with spindles that accept Schaublin F16 76-1076, E1212, Southwick & Meister TF16 and Hardinge TF16 / 4609 collets. UM5 Microconic ColletsAlong with the new smaller cartridges comes a comprehensive series of UM5 collets that are ideally suited for small diameter part sizes ranging from 0.2mm/.008" to 5.5mm/.217" in diameter. These are available in regular type UM5 collets as well as all three types of Microconic's T, V and W type Over-Grip collets. Masa Tool offers the most unique variety of over-grip collets in the industry. Micrograd UM5 Dial WrenchA full set of UM5 accessory products has also been introduced including a a UM5 series of Microguide EGS™ ejection guide sleeves and a new UM5 Micrograd™ Dial Wrench which is included with the purchase of any of the Microconic Cartridges. Mircrograd Dial Wrenches for the UM5 collets are now available in both metric, CW5-M, and imperial increments CW5-E. The Micrograd™ Dial Wrenches provides a method of precisely setting clamping pressure on both the regular Microconic collets and on all series of Microconic over-grip collets. It can be adjusted in an infinite number of increments between the metric graduations of 0,02mm and inch/imperial graduations of .001" With the Micrograd Dial you can document the micrometer-adjust collet closure in your set up plan so it's done the same every time, regardless of operator skill and without relying on "feel". Microconic: Game Changing Technology for Small PartsMasa’s Cartridge and Collet assembly is designed to vector the chucking force directly over the holding surface. This means that the chucking force can be reduced while at the same time the holding power is increased. This opens up the possibility of shifting part operations from the main to the sub-spindle and dramatically reducing cycle time. 20% ~ 40% cycle time reduction is commonly achieved. These new cartridges, collets and accessories will be demonstrated for the first time at IMTS 2022 in the West Building, Level 3 — 432163 — Tooling & Workholding Systems IMTS Press BriefingJoin Masa Tool at Booth 432163 West Building, Level 3 TUESDAY SEPTEMBER 13 AT 3:30PM central time We will introduce our NEW Microconic products for Swiss-type CNC Workholding! Featuring Masa Tool's expands its Microconic system at IMTS 2022: The F15M5 & F16M5 cartridges and accompanying NEW UM5 collet series which includes over-grip collets and Micrograd Dial Wrench to achieve superior stability with precise, calibrated, repeatable setting of collet closure

To avoid crushing and ruining parts, Swiss precision manufacturer Micro-Matics turned to Masa Tool’s Microconic collet and cartridge system. Since 1973, Micro-Matics of Fridley, MN, has been manufacturing CNC Swiss precision screw machine products including many kinds of contacts & pins, ground shafts, hardened bushings, rivets, screws, spacers and other custom parts for the medical, dental, aerospace, commercial, defense, computer, telecommunications and automotive industries. According to Jason Wobig, Operations Manager, "Micro-Matics is primarily an aerospace and medical components, Swiss machining job shop. We make components that are thousandths of an inch up to an 1-1/4" in diameter. We started out with the old manual style, Cam driven Swiss machines and we're one of the largest Escomatic shops in the Midwest. And as the company's grown and evolved, we've turned into Swiss job shop, mostly Citizen machines like the M16, a L12, and a M32, as well as a few Star and Tsugami machines that give us a wide variety of capabilities."

|

| A while back Micro-Matics was running a small medical part, a catheter part, that they were struggling with. They had some custom collets made for pickoff and, according to Dave Thayer, Department Manager, "It was a constant struggle. This particular catheter part has very thin walls, it got crushed with a standard M16 collet system because you have very little accuracy in how much tension you're putting on your collet. If you put too much force on it, my parts started turning to collapse into triangles. If you don't have enough tension on it, the part pushes back into the pickoff and you get varying part lengths and varying chamfer diameters. The parts would be out round and they wouldn't be on-center." Wobig had heard about Masa Tool's Microconic™ sytems through Todd Pakiz, President of High Tech Representation Inc., New Prague, Minnesota. "Todd had told me about this system a couple years back. And we had been struggling with these parts. So I reached out to Todd and see if he's still selling that system." |

| Wobig continues, "I wanted to try this system for the catheter part which is a small thin-walled part approximately 0.040" in diameter and another 0.040" in length and with a wall thickness of 0.010". So I wanted something that wasn't crushing the part. It was really hard to adjust the machines pickoff spindle itself to any degree of accuracy without crushing a part." What Wobig found with the Masa Microconic system was that they could set up the clamping with a gage pin and set the clamping tension with the Micrograd™ Dial Wrench which has little indicators to set an actual tension. |

Cartridge and collet solution

The Microconic system consists of a cartridge and collet, with the cartridge fitting in the machine just like a standard legacy collet. The cartridge is a self-contained precision mechanism using the machine’s standard collet closing function, which means that the Microconic system can be used on any machine utilizing 5C, TF20, TF25 or TF37 collets.

According to Saccomanno "Since a collet system for any given machine must be made large enough to fit the maximum workpiece diameter capacity of the machine, the result is the standard collet mechanism is designed to handle the largest workpieces, which means it is excessively forceful and bulky when used for the smaller workpieces. Smaller parts get sacrificed, because they typically require a higher degree of accuracy and the workholding is more critical."

The Microconic system consists of the cartridge, which fits into your machine like a standard collet, and the Microconic collets which fit into Masa's unique cartridge. Every Microconic cartridge comes standard with extended nose for unsurpassed rigidity because of it's single piece construction.

"In fact, the cartridge is so accurate that it can be used as a gauge to verify machine spindle accuracy," said Pakiz.

Thayer explained how the Microconic system has worked for Micro-Matics "With the Masa system we're able to dial in a nice specific tension to hold that catheter part without crushing it or deforming it at all and having it on center. In a nutshell, we get better quality parts consistently with tighter tolerances. It's lead to a really significant improvement, it's increased throughput, so we have more parts at the end of the day."

"As a result of the implementation, the scrap rate on this part dropped dramatically once we added the new Masa system by at least 30%." added Wobig.

According to Masa Tool, the Microconic cartridge concentricity is guaranteed to be within 5µm (.0002") runnout and the collets are hardened and precision ground to the highest quality standards. The regular, UM10, 10mm collets, that Micro-Matics is using in their F20M10 Cartidge are available from Ø0.2mm (.008") to 10mm (.394"). In additon to the TF 20 spindles, the same collets can be used in TF25, TF37 and 5C sub spindles.

Applying technology to other applications

Micro-Matics has been running one of the collets for a couple of months straight now on a distal coupler.

Thayer explains, "The distal coupler part has a unique shape. It's not perfectly round. It has some small flats milled on either side of the part. It's like a cylindrical pill, like a capsule except with two sides of the long length milled in so there's flats on it. The part is 0.080" in length 0.040" in a cylindrical diameter. We then mill the cylindrical diameter 180 degrees from each other to a thickness of 0.030", so you're taking 0.10" off then drilling and centering two holes on each end of that through the flats."

"Our customer is extremely concerned about any collet indication marks or chip marks on the outside of that cylindrical diameter. The previous collets we were using were custom made collets that actually had the profile of the part basically machined into it" says Wobig.

| Thayer picks it up, "It was a straight cylinder round collet it but it was split in half so it was like two halves of a collet so we were trying to keep the flats in the spaces and then the round cylinder on the collet part that's round. The holding portion it would move and we didn't have them pinned at all. And then we had the same issue as on the catheter part: If you squeeze it too tight you're starting to push the diameter into the flat so it would deform the OD into the flat and make deformed flats. If you squeezed it too hard, it would make the flat bump up. If it didn't sit perfectly right in the custom collet you'd have the split marks of the collet that start interfering with the transition between the flat to the diameter and it would make lines on the diameter." | |

Remedying the issues

Thayer continued "The extended nose pieces on the Microconic cartridge helps on the catheter tips because you can get closer up to where I actually have a supporting back end. Because if I'm too far away from that supporting back and you have more of a tendency to crush the front of that part. The Microconic gives me a better tension on the part. On the distal coupler, we have to use a boring bar, or a facing tool to create the back face, which is round. We'd have a lot of trouble trying to hold without nibs or anything on there. And this holds it so that the part stays a little more square, and we're able to turn it better."

When dealing with very small parts and setting with small gage pins, accidents do sometimes happen. "The only problem I've had with it was when somebody was trying to set the collet tension with a pin. They put the pin into the slot and not the hole and wrecked the collet. Because the pin was able to fit inside the slot so when they started tightening it up, and the pins started deforming the collet was wrecked because it wasn't in the hole in the center." said Thayer.

Masa has indicated that they will release a new TF 15 and TF16 Cartridge with an entire series of smaller 5mm capacity collets at IMTS 2022.

Specificationz

Microconic over-grip collets have unmatched rigidity and concentricity compared to other manufacturers. The same collets can be used in TF20, TF25, and 5C sub spindles. Microconic collets permit interchangeability between machines, and the collets fit in any Microconic cartridge, no matter which collet system is in the machine.

New release

| The 2018-2019 catalog features NEW PRODUCTS including:

The Microconic system provides: |

- Solid extended nose — extremely rigid

- Micrometer-adjust control of collet closure — even the most fragile parts can be held safely and firmly.

- Extreme accuracy — concentricity within 5μm (0.0002”) runout.

- The Microconic cartridge can be used as a gauge to verify machine spindle accuracy.

- Collets available from Ø0.2mm (0.008”) to 10mm (0.394”).

- All collets hardened and precision ground to the highest quality standards.

- Over-grip collets with performance unlike anything else! Open 4mm larger than the clamping diameter. Unmatched rigidity and concentricity. If you have tried other over-grip collets then you will be shocked at the difference — our Microconic over-grip collets are amazing.

- The Microconic collets fit in any Microconic cartridge, no matter which machine.

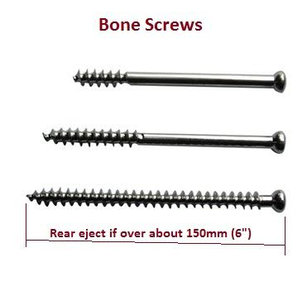

A critical aspect to using over-grip collets is to make sure the part is ejected reliably when it is completed being machined. Due to the wide opening of the over-grip collets, parts can get jammed in the collet slot. As a result, the collet will be damaged or break when it is closed.

Every Microconic over-grip collet is supplied with a blank Microguide EGS ejection guide sleeve that you can drill to size to fit your specific part to enable the finished part to be ejected consistently without damage to the over-grip collet. The EGS is meant to be drilled through with a loose-fitting hole that will support and help guide the workpiece as it is ejected from the collet. Users can customize the Microguide EGS to match their specific workpiece and method of ejection.

EGS10-01 for UM10W-(ALL) 360 Brass

EGS10-02 for UM10V-(ALL) 360 Brass

EGS10-03 for UM10W-(ALL) 303 Stainless Steel

EGS10-04 for UM10V-(ALL) 303 Stainless Steel

EGS10-05 for UM10W-(ALL) Acetal (Delrin)

EGS10-06 for UM10V-(ALL) Acetal (Delrin)

EGS10-07 for UM10T-20 to -240 360 Brass

EGS10-08 for UM10T-245 to -325 360 Brass

EGS10-09 for UM10T-330 to -420 360 Brass

EGS10-10 for UM10T-425 to -530 360 Brass

EGS10-11 for UM10T-535 to -635 360 Brass

EGS10-12 for UM10-(ALL) 360 Brass (15mm length rear extension)

They are our part number EGS10-12.

It was the cover story entitled: "Micro-Precision Machining" by Elizabeth Modic

“The cartridge can be used as a calibration gage to verify the machine spindle accuracy,” Co-owner Chip Prescott notes.

Microconic collets are finished to exacting standards with a five-step grinding process that removes the effect of heat-treat warpage. Also, the proprietary Microconic form of the closure surfaces is inherently more accurate than traditional collets, providing for a greater full-accuracy working range.

Cartridges are available to fit in push-type dead-length collet closers and also draw-type closers: F20M10 (for TF20 collet replacement), F25M10 (for TF25 collet replacement), and 5CM10 (for 5C collet replacement). All of these cartridges use the same Microconic UM10 collets, with more cartridge sizes in development to be released soon.

Author

Here you will find the latest press releases, news coverage and technical information about our Microconic™ system

Archives

February 2023

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

January 2022

October 2021

May 2021

July 2020

March 2020

February 2020

December 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

June 2017

May 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

March 2016

February 2016

January 2016

December 2015

November 2015

October 2015

September 2015

August 2015

July 2015

May 2015

April 2015

August 2014

May 2014

March 2014

July 1999

Categories

All

5C Cartridge

5C Collet

Advanced Manufacturing

Advertisement

Agent Profile

AMTS

APT Machine Tools

Avinger

Bell Mouthing

Bone Screws

Case Study

Catalog

CEO CFO

Chip Wrapping

Cincom

Cincom L12

Cincom L20

Cincom M16

Cincom M32

CNC West

Collet

Concentricity

Dental Implants

Dragan Marjanovic

Dunner SA

Eastec

Ejection Guide Sleeve

Emergency Collet

F13M5

F15M5

F16M5

F201M10

F20M10

F37M10

Floyd Automatic

Ganesh

High Tech Industrial

IMTS

ISwiss

Jones Marketing

Lane 4

Machinery Trade International

Magazine Article

Mann Sales

Marubeni Citizen

Material: 6Al4V

MAV Innovations

Metal Cutting Corp

Microconic

Micrograd Wrench

Microguide Sleeve

Micromachining

Micro-Matics

Modern Machine Shop

Morris South

NETC

Next Generation Tooling

Oceanside Facility

Oktoberfest

Open House

Overgrip Collet

Part: Counterbore Drills

Part: Dental Drills

Part: Dental Impant

Part: Medical Device

Part: Surgical Drills

Part: Surgical Taps

PMTS

Press Release

Production Machining

Productivity Inc.

Ram Sales & Marketing

Schlenker

SIAMS

South Tec

South- Tec

Star CNC

Star SR20

STEM

Tech Tip

TF15

TF16

TF20

TF25

TF37

Todays Medical Developments

Tool Marketing Service

Trade Show

Trade Shows

Tsugami

UM10

UM10T

UM10W

UM5

UM5T

UM5V

UM5W

Videos

Workpiece Deflection

RSS Feed

RSS Feed