|

To avoid crushing and ruining parts, Swiss precision manufacturer Micro-Matics turned to Masa Tool’s Microconic collet and cartridge system. Since 1973, Micro-Matics of Fridley, MN, has been manufacturing CNC Swiss precision screw machine products including many kinds of contacts & pins, ground shafts, hardened bushings, rivets, screws, spacers and other custom parts for the medical, dental, aerospace, commercial, defense, computer, telecommunications and automotive industries. According to Jason Wobig, Operations Manager, "Micro-Matics is primarily an aerospace and medical components, Swiss machining job shop. We make components that are thousandths of an inch up to an 1-1/4" in diameter. We started out with the old manual style, Cam driven Swiss machines and we're one of the largest Escomatic shops in the Midwest. And as the company's grown and evolved, we've turned into Swiss job shop, mostly Citizen machines like the M16, a L12, and a M32, as well as a few Star and Tsugami machines that give us a wide variety of capabilities."

|

|||||||||||||||||||||||||||||||||||||||||

| A while back Micro-Matics was running a small medical part, a catheter part, that they were struggling with. They had some custom collets made for pickoff and, according to Dave Thayer, Department Manager, "It was a constant struggle. This particular catheter part has very thin walls, it got crushed with a standard M16 collet system because you have very little accuracy in how much tension you're putting on your collet. If you put too much force on it, my parts started turning to collapse into triangles. If you don't have enough tension on it, the part pushes back into the pickoff and you get varying part lengths and varying chamfer diameters. The parts would be out round and they wouldn't be on-center." Wobig had heard about Masa Tool's Microconic™ sytems through Todd Pakiz, President of High Tech Representation Inc., New Prague, Minnesota. "Todd had told me about this system a couple years back. And we had been struggling with these parts. So I reached out to Todd and see if he's still selling that system." |

| Wobig continues, "I wanted to try this system for the catheter part which is a small thin-walled part approximately 0.040" in diameter and another 0.040" in length and with a wall thickness of 0.010". So I wanted something that wasn't crushing the part. It was really hard to adjust the machines pickoff spindle itself to any degree of accuracy without crushing a part." What Wobig found with the Masa Microconic system was that they could set up the clamping with a gage pin and set the clamping tension with the Micrograd™ Dial Wrench which has little indicators to set an actual tension. |

Cartridge and collet solution

The Microconic system consists of a cartridge and collet, with the cartridge fitting in the machine just like a standard legacy collet. The cartridge is a self-contained precision mechanism using the machine’s standard collet closing function, which means that the Microconic system can be used on any machine utilizing 5C, TF20, TF25 or TF37 collets.

According to Saccomanno "Since a collet system for any given machine must be made large enough to fit the maximum workpiece diameter capacity of the machine, the result is the standard collet mechanism is designed to handle the largest workpieces, which means it is excessively forceful and bulky when used for the smaller workpieces. Smaller parts get sacrificed, because they typically require a higher degree of accuracy and the workholding is more critical."

The Microconic system consists of the cartridge, which fits into your machine like a standard collet, and the Microconic collets which fit into Masa's unique cartridge. Every Microconic cartridge comes standard with extended nose for unsurpassed rigidity because of it's single piece construction.

"In fact, the cartridge is so accurate that it can be used as a gauge to verify machine spindle accuracy," said Pakiz.

Thayer explained how the Microconic system has worked for Micro-Matics "With the Masa system we're able to dial in a nice specific tension to hold that catheter part without crushing it or deforming it at all and having it on center. In a nutshell, we get better quality parts consistently with tighter tolerances. It's lead to a really significant improvement, it's increased throughput, so we have more parts at the end of the day."

"As a result of the implementation, the scrap rate on this part dropped dramatically once we added the new Masa system by at least 30%." added Wobig.

According to Masa Tool, the Microconic cartridge concentricity is guaranteed to be within 5µm (.0002") runnout and the collets are hardened and precision ground to the highest quality standards. The regular, UM10, 10mm collets, that Micro-Matics is using in their F20M10 Cartidge are available from Ø0.2mm (.008") to 10mm (.394"). In additon to the TF 20 spindles, the same collets can be used in TF25, TF37 and 5C sub spindles.

Applying technology to other applications

Micro-Matics has been running one of the collets for a couple of months straight now on a distal coupler.

Thayer explains, "The distal coupler part has a unique shape. It's not perfectly round. It has some small flats milled on either side of the part. It's like a cylindrical pill, like a capsule except with two sides of the long length milled in so there's flats on it. The part is 0.080" in length 0.040" in a cylindrical diameter. We then mill the cylindrical diameter 180 degrees from each other to a thickness of 0.030", so you're taking 0.10" off then drilling and centering two holes on each end of that through the flats."

"Our customer is extremely concerned about any collet indication marks or chip marks on the outside of that cylindrical diameter. The previous collets we were using were custom made collets that actually had the profile of the part basically machined into it" says Wobig.

| Thayer picks it up, "It was a straight cylinder round collet it but it was split in half so it was like two halves of a collet so we were trying to keep the flats in the spaces and then the round cylinder on the collet part that's round. The holding portion it would move and we didn't have them pinned at all. And then we had the same issue as on the catheter part: If you squeeze it too tight you're starting to push the diameter into the flat so it would deform the OD into the flat and make deformed flats. If you squeezed it too hard, it would make the flat bump up. If it didn't sit perfectly right in the custom collet you'd have the split marks of the collet that start interfering with the transition between the flat to the diameter and it would make lines on the diameter." | |

Remedying the issues

Thayer continued "The extended nose pieces on the Microconic cartridge helps on the catheter tips because you can get closer up to where I actually have a supporting back end. Because if I'm too far away from that supporting back and you have more of a tendency to crush the front of that part. The Microconic gives me a better tension on the part. On the distal coupler, we have to use a boring bar, or a facing tool to create the back face, which is round. We'd have a lot of trouble trying to hold without nibs or anything on there. And this holds it so that the part stays a little more square, and we're able to turn it better."

When dealing with very small parts and setting with small gage pins, accidents do sometimes happen. "The only problem I've had with it was when somebody was trying to set the collet tension with a pin. They put the pin into the slot and not the hole and wrecked the collet. Because the pin was able to fit inside the slot so when they started tightening it up, and the pins started deforming the collet was wrecked because it wasn't in the hole in the center." said Thayer.

Masa has indicated that they will release a new TF 15 and TF16 Cartridge with an entire series of smaller 5mm capacity collets at IMTS 2022.

Specificationz

Microconic over-grip collets have unmatched rigidity and concentricity compared to other manufacturers. The same collets can be used in TF20, TF25, and 5C sub spindles. Microconic collets permit interchangeability between machines, and the collets fit in any Microconic cartridge, no matter which collet system is in the machine.

New release

| The 2018-2019 catalog features NEW PRODUCTS including:

The Microconic system provides: |

- Solid extended nose — extremely rigid

- Micrometer-adjust control of collet closure — even the most fragile parts can be held safely and firmly.

- Extreme accuracy — concentricity within 5μm (0.0002”) runout.

- The Microconic cartridge can be used as a gauge to verify machine spindle accuracy.

- Collets available from Ø0.2mm (0.008”) to 10mm (0.394”).

- All collets hardened and precision ground to the highest quality standards.

- Over-grip collets with performance unlike anything else! Open 4mm larger than the clamping diameter. Unmatched rigidity and concentricity. If you have tried other over-grip collets then you will be shocked at the difference — our Microconic over-grip collets are amazing.

- The Microconic collets fit in any Microconic cartridge, no matter which machine.

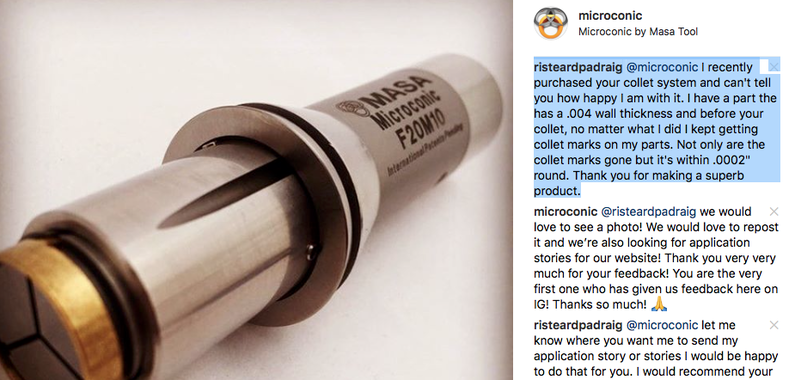

| Recently, Rich Swift from Metal Cutting Corporation, reached out to Masa Tool on Instagram, @Microconic, and told us: "I recently purchased your collet system and can't tell you how happy I am with it. I have a part the has a .004 wall thickness and before your collet, no matter what I did I kept getting collet marks on my parts. Not only are the collet marks gone but it's within .0002" round. Thank you for making a superb product." |

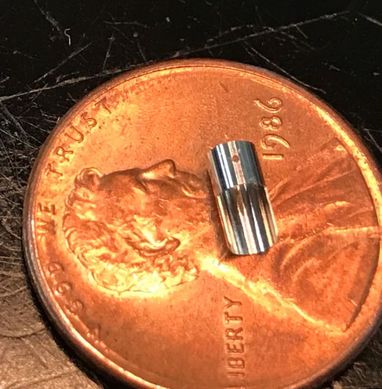

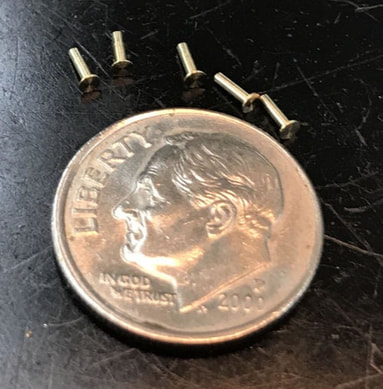

| According to Rich, "The pictures with the part on the penny is the one I mentioned on Instagram. I have work on this part for the past 5 years and just when I was ready to throw in the towel I saw an adverstisment for your Microconic collet system in Production Machining Magazine. I got in touch with Doug Brown, the Vice President of Allendale Machinery here in North Jersey, and he put me in touch with Masa Tool's regional manager Mark Bergonzi." |

About Metal Cutting Corporation

Their specialty has always been small diameter parts made from all metals.

"The parts can be long but are most often short, often very short."

When the company started in the late 1960's they primarily worked with non-ferrous metals, especially tungsten and molybdenum. So much so that in 1984 they became the exclusive North American distributor for Nippon Tungsten Co., Ltd.’s tungsten and molybdenum products. Since the the 1980's they have been working with and machining more stainless steel and now have a developed a deep knowledge of machining the newer nickel and titanium based alloys.

| Mark, from Masa, and and Doug, from Allendale Machinery, visited Rich at Metal Cutting. According to Rich, "I was sold before he could get it out of his demo case." "Since this part is a medical part every thing had to be perfect. Ever since I purchased the Microconic system our customer has been very pleased with our parts and, believe it or not, it has less burrs than before." | |

Marubeni Citizen-Cincom is the exclusive New England distributor for Citizen Cincom Swiss style lathes and Miyano Multi Axis turning centers as well as ne of our premier distributors of the Micorconic Workholding system

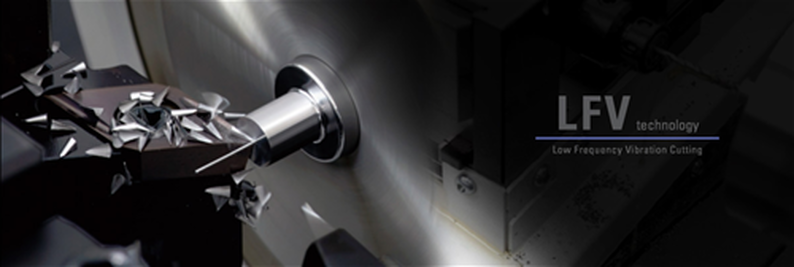

About the CINCOM L20 Low Frequency Vibration (LFV)

The popular Citizen CINCOM L20 series sliding headstock lathes are now available with Low Frequency Vibration (LFV).

This widely applicable cutting technology – able to handle a broad range of machining shapes and materials – is ideal for cutting difficult-to-cut materials. The state-of-the-art LFV suppresses various risks associated with these materials, such as entanglement of chips and built-up edges.

Depending on the material being cut, a variety of problems can be caused by chips getting entangled with each other, including increased cutting resistance, scarring, changes in the texture of the machined surface, tool nose damage, and built-up edges due to cutting heat. In LFV cutting, “air cutting” time prevents the machining temperature from rising, which both prolongs tool lives and gives relief from various problems caused by chips.

It was the cover story entitled: "Micro-Precision Machining" by Elizabeth Modic

“The cartridge can be used as a calibration gage to verify the machine spindle accuracy,” Co-owner Chip Prescott notes.

Microconic collets are finished to exacting standards with a five-step grinding process that removes the effect of heat-treat warpage. Also, the proprietary Microconic form of the closure surfaces is inherently more accurate than traditional collets, providing for a greater full-accuracy working range.

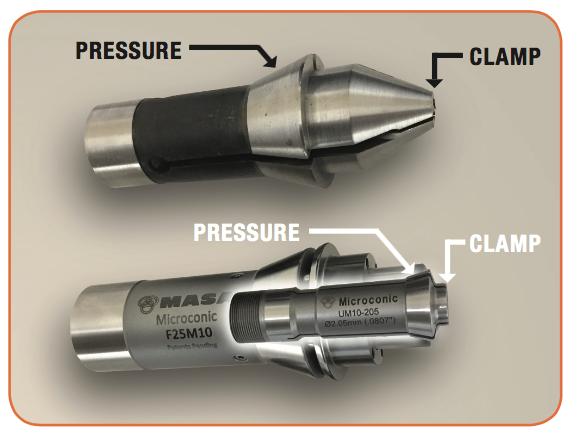

Cartridges are available to fit in push-type dead-length collet closers and also draw-type closers: F20M10 (for TF20 collet replacement), F25M10 (for TF25 collet replacement), and 5CM10 (for 5C collet replacement). All of these cartridges use the same Microconic UM10 collets, with more cartridge sizes in development to be released soon.

The Microconic system consists of two primary components: a cartridge that fits in the machine’s standard TF20, TF25 or 5C collet closer, and the collet itself, which fits into the cartridge. Each cartridge model has a solid extended nose and can accept both regular and over-grip collets. The over-grip collets open up to 0.157" (4 mm) larger than the clamping diameter.

The Microconic cartridge’s extended nose design directs all of the chucking pressure directly over the workpiece for concentricity and rigidity. Total indicated runout (TIR) for the Microconic system is guaranteed at 0.0002" (5 µm) at the workpiece, absent any runout introduced by the machine structure or other elements of the setup. The system capacity ranges from 0.008" to 0.394" (0.2 to 10 mm) in diameter, with all sizes available from stock.

| This article originally appeared in Production Machining 2/27/2017 Jedd Cole, Editor Editor Asistente, MMS Mexico |

We've got pictures of the article below in case you don't currently subscribe to Modern Machine Shop. You can also download a PDF copy of the entire June issue below in the link. It starts on Page 25 of the PDF download. If you have the print edition it's on Page 22, or you can just read thought the screen shots below.

We want to really extend a very big THANK YOU to Matt Danforth at Modern Machine Shop who wrote this article. Matt really did an awful lot of work learning about the various features of our system. We know there where many many hours that he spent to develop this story just from the sheer number of follow up questions and conversations. We really have an awful lot of respect for the entire MMS team and the effort they put into getting their story's "just right".

Download MMS June 2017 Issue HERE >>>>>>>>>>>>>>>>>>>>>>>>>> |

| ||||||

It was the cover story entitled: "Micro-Precision Machining"

By Elizabeth Modic

| In 1996, Matt Saccomanno, co-founder of Masa Tool, was frustrated with the limitations of conventional collets and workholding systems when performing secondary machining operations as engineering manager at Allied Swiss Screw Products. This was in the early days of CNC Swiss-type machines, when machining capabilities were limited, requiring lots of secondary operations. His solution – a high-precision, collet-type workholding device for small parts machining. As machining capabilities advanced and precision requirements became more challenging, Saccomanno realized that the legacy collet systems used in micro-machining were a serious limiting factor that prevented full use of modern machine capabilities. That prompted Saccomanno to design the next generation, the Microconic system. |

The Microconic system will be able to do things that are impossible

with any other traditional collet system.

The Masa Microconic system consists of the cartridge, which fits into your machine like a standard collet, and the Microconic collets which fit into the cartridge

| Our regular MicroconicTM collets help reduce cycle time by allowing a rm grip on the workpiece without causing damage, and yet holding it much more rigidly than any other collet on the market. You’ll be able to do heavy machining operations in the sub spindle, such as blind hole broaching, that would not have even considered in the past. Now you can switch ops from main to sub! Set ups are quicker and more repeatable with Microconic. You can document the micrometer-adjust collet closure in your set up plan using our Micrograd Face Dial Wrench and it’s going to repeat to the same clamping pressure each and every time, regardless of operator skill and without relying on “feel”. You can calibrate your spindle accuracy with the MicroconicTM cartridge by using it as a precision cylinder gauge. When that is good, EVERY Microconic collet will run within .0002” TIR: There’s no ddling and swapping collet after collet looking for a “good” one. Set ups go smoothly and predictably. | The Microconic collets fit into our cartridge to hold the workpiece with great precision and rigidity. Unlike traditional extended nose collets our unique design and closing action is inherently more accurate and consistent. The clamping force is directly over the workpiece at the end of the collet. The origin of the word “Microconic”, alludes to the precise way in which the collet closing taper is formed to cancel the effects of heat treat warp and grind tolerances. As a result, it provides industry- best concentricity every time. |

Download or View the 2017 Masa Tool Microconic Catalog:

Blog: 2/17/2017

by MATT DANFORD

Associate Editor, Modern Machine Shop

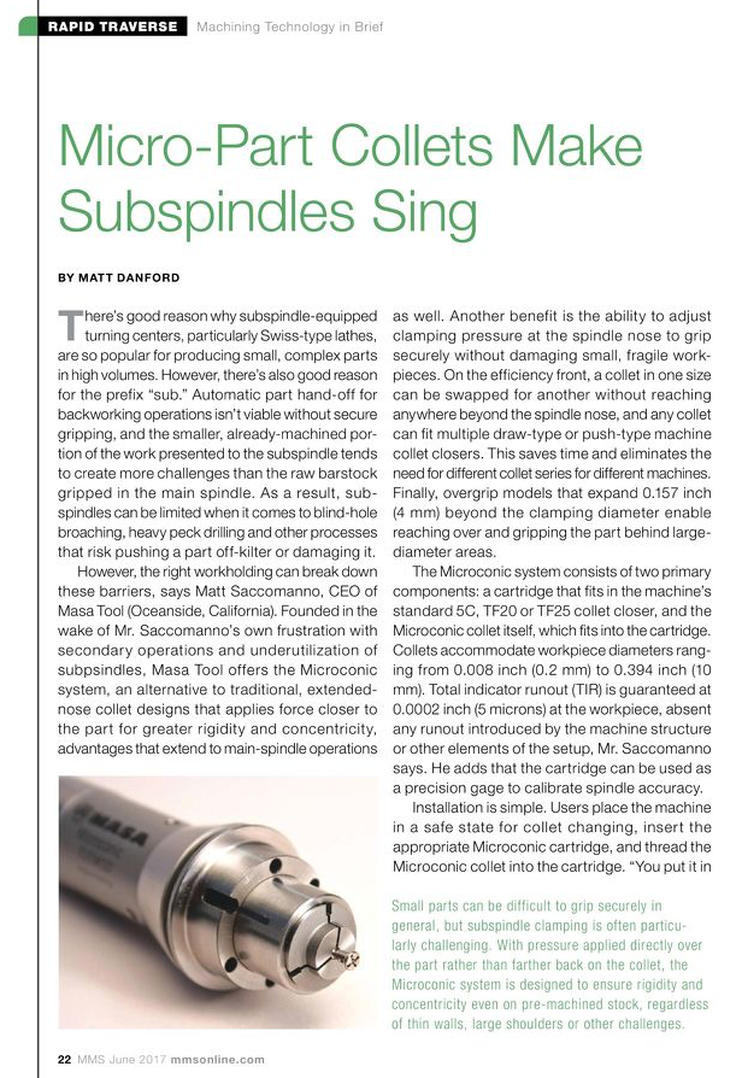

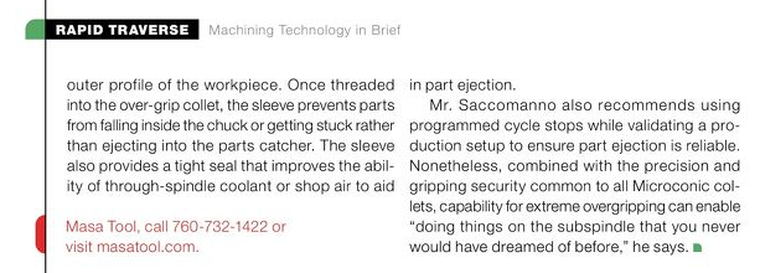

| However, the right workholding can break down these barriers, says Matt Saccomanno, CEO of Masa Tool (Oceanside, California). Founded in the wake of Mr. Saccomanno’s own frustration with secondary operations and underutilization of subpsindles, Masa Tool offers the Microconic system, an alternative to traditional, extended-nose collet designs that applies force closer to the part for greater rigidity and concentricity—advantages that extend to main-spindle operations as well. Another benefit is the ability to adjust clamping pressure at the spindle nose to grip securely without damaging small, fragile workpieces. On the efficiency front, a collet in one size can be swapped for another without reaching anywhere beyond the spindle nose, and any collet can fit multiple draw-type or push-type machine collet closers. This saves time and eliminates the need for different collet series for different machines. |

| The Microconic system consists of two primary components: a cartridge that fits in the machine’s standard 5C, TF20 or TF25 collet closer, and the Microconic collet itself, which fits into the cartridge. Collets accommodate workpiece diameters ranging from 0.008 inch (0.2 mm) to 0.394 inch (10 mm). Total indicator runout (TIR) is guaranteed at 0.0002 inch (5 microns) at the workpiece, absent any runout introduced by the machine structure or other elements of the setup, Mr. Saccomanno says. He adds that the cartridge can be used as a precision gage to calibrate spindle accuracy. |

| There’s no “feel” involved in tightening the collet, he says. That’s a task accomplished with the company’s Micrograd wrench, which features micrometer graduations of 0.001 inch (0.02 mm) to aid users in dialing in the perfect closure on either a workpiece or a gage pin of the same size. This configuration relegates the machine’s own clamping mechanism to the role of an actuator that triggers the opening or closing of the collet. As such, he advises keeping the machine’s own function at a medium force setting and allowing the Microconic cartridge to control the actual chucking force. Machined from a single piece of hardened steel, the cartridge preserves the dead-length operation of “push-type” collet systems (that is, the collet itself doesn’t move in or out as the machine cartridge actuates the chuck). |

| He credits much of that precision to the fact that clamping force is applied directly over the workpiece, a contrast with traditional extended-nose designs that apply force farther back. He also credits the manufacturing process. Tapering collet jaws to interface with the machine is nothing unusual. However, Masa Tool employs a proprietary, five-step grinding process that leaves each jaw with a particularly precise conical shape (hence the name “Microconic”) that forms a particularly tight fit. More specifically, a “slight crown” ensures that the contact point is always centered, he explains, citing the pattern of wear marks on well-used collets as evidence. |

| Gripping wasn’t the company’s only focus when designing the Micronic system. Reliable part ejection is also critical, Mr. Saccomanno says, particularly with overgrip collets that offer such a wide gripping range. That’s why overgrip models ship with a Microject, a brass ejection guide sleeve that can be machined to mirror the outer profile of the workpiece. Once threaded into the over-grip collet, the sleeve prevents parts from falling inside the chuck or getting stuck rather than ejecting into the parts catcher. The sleeve also provides a tight seal that improves the ability of through-spindle coolant or shop air to aid in part ejection. |

Author

Here you will find the latest press releases, news coverage and technical information about our Microconic™ system

Archives

February 2023

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

January 2022

October 2021

May 2021

July 2020

March 2020

February 2020

December 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

June 2017

May 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

March 2016

February 2016

January 2016

December 2015

November 2015

October 2015

September 2015

August 2015

July 2015

May 2015

April 2015

August 2014

May 2014

March 2014

July 1999

Categories

All

5C Cartridge

5C Collet

Advanced Manufacturing

Advertisement

Agent Profile

AMTS

APT Machine Tools

Avinger

Bell Mouthing

Bone Screws

Case Study

Catalog

CEO CFO

Chip Wrapping

Cincom

Cincom L12

Cincom L20

Cincom M16

Cincom M32

CNC West

Collet

Concentricity

Dental Implants

Dragan Marjanovic

Dunner SA

Eastec

Ejection Guide Sleeve

Emergency Collet

F13M5

F15M5

F16M5

F201M10

F20M10

F37M10

Floyd Automatic

Ganesh

High Tech Industrial

IMTS

ISwiss

Jones Marketing

Lane 4

Machinery Trade International

Magazine Article

Mann Sales

Marubeni Citizen

Material: 6Al4V

MAV Innovations

Metal Cutting Corp

Microconic

Micrograd Wrench

Microguide Sleeve

Micromachining

Micro-Matics

Modern Machine Shop

Morris South

NETC

Next Generation Tooling

Oceanside Facility

Oktoberfest

Open House

Overgrip Collet

Part: Counterbore Drills

Part: Dental Drills

Part: Dental Impant

Part: Medical Device

Part: Surgical Drills

Part: Surgical Taps

PMTS

Press Release

Production Machining

Productivity Inc.

Ram Sales & Marketing

Schlenker

SIAMS

South Tec

South- Tec

Star CNC

Star SR20

STEM

Tech Tip

TF15

TF16

TF20

TF25

TF37

Todays Medical Developments

Tool Marketing Service

Trade Show

Trade Shows

Tsugami

UM10

UM10T

UM10W

UM5

UM5T

UM5V

UM5W

Videos

Workpiece Deflection

RSS Feed

RSS Feed