|

A Swiss CNC machine shop presented us with several problems related to long cycle times and poor tool life with a high-volume group of Dental Surgical Drills, Taps, and Counterbore Drills with standard ISO shank configuration.

Before Microconic: The Workholding ProblemsBefore implementing the Microconic solution there were a number of problems:

3 Comments

Matt goes on to explain how the Microconic System solves all of the problems with traditional pickoff collet with a guaranteed 0002" TIR accuracy and ships everything from stock within two days of placing an order! Masa Tool's Microconic cartridge is made of exotic high-chromium tool steel, triple tempered and cryogenically treated to provide stable construction. All functional seating surfaces are ground with extreme precision on a one-piece, ultra-rigid body structure.

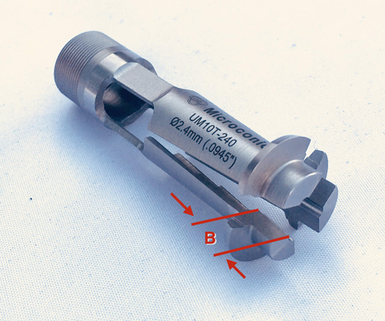

“The cartridge can be used as a calibration gage to verify the machine spindle accuracy,” Co-owner Chip Prescott notes. Microconic collets are finished to exacting standards with a five-step grinding process that removes the effect of heat-treat warpage. Also, the proprietary Microconic form of the closure surfaces is inherently more accurate than traditional collets, providing for a greater full-accuracy working range. Cartridges are available to fit in push-type dead-length collet closers and also draw-type closers: F20M10 (for TF20 collet replacement), F25M10 (for TF25 collet replacement), and 5CM10 (for 5C collet replacement). All of these cartridges use the same Microconic UM10 collets, with more cartridge sizes in development to be released soon. High precision long nose collet system for sliding-head Swiss-type CNC lathe/turning centers. Opens 4mm larger than clamping diameter! Super accurate, super rigid. As a critical industry supplier, Masa Tool remains operational with appropriate precautions, and shipments are occurring normally, within 2 days of order. We are suspending our same-day expedite for now. If order deliveries are delayed we will notify accordingly.

Thanks for your understanding. Best wishes to all for your health and safety! Please send all new orders to [email protected] Wiha: Family business with a high level of vertical integration Founded 80 years ago as a small company by Willi Hahn, Wiha Werkzeuge is now a global company with production sites in Vietnam, Poland, Germany and Switzerland. In the second generation, his son Wilfried Hahn, who is still part of the management team today, built up a global company network that is currently managed by the founder's grandson, Wilhelm Hahn. The Mönchweiler plant is the location for the company's VDE tools. The screwdrivers and bits that are manufactured here are usually coated with plastic to protect the user from electric shocks. According to Andreas Stengele, head of the Langdreher / Bits department at Wiha, the resulting very high demands on security and quality still justify production in the high-wage location of Germany. The plant, or the entire company, impresses with a high level of vertical integration. Even the hardening process and the surface treatment take place on site. Only the electroplating is done externally. Clamping technology specialist at the hand tool manufacturer In production at the Mönchweiler location, Wiha relies on a total of 13 Swiss-type lathes from various manufacturers. The Schlenker company, which is based in nearby Villingen-Schwenningen, has made special modifications to some of the Swiss-made lathe machines and, for example, modified the mounting of the counter spindle. The fine line of proper leadership Bits for screwdrivers are a core product in Mönchweiler: Wiha produced 1.1 million of these components in 2018 from low-alloy spring tool steel, mostly in batches of around 5,000. The raw material is provided in hexagonal bars, each three meters in length. During machining, very high concentricity and roundness requirements are placed on the parts. If this is not the case, the insulating plastic layer will be distributed unevenly during overmolding and the risk of breakdown when working with the screwing aid increases. Particularly in the area of guide bushes on Swiss-type lathes, it is difficult to meet the requirements in terms of both concentricity and roundness. According to Andreas Stengele, this is due to the diameter of the material used: “We work in the diameter range of three to four millimeters, but we use much larger machines. Because the smaller machines offer neither the necessary tool positions nor the necessary performance. ”The hexagonal bars are clamped with the main collet and guided through a guide bush. If it is too narrow, the material will bend when it is fed. However, if it is too loose, concentricity and roundness will suffer. “That's why it's always a fine line how I adjust the guide bushing,” says the expert. Conventional, adjustable guide bushes can be adjusted using a thread. Flexible guide bushes, on the other hand, such as those offered by Schlenker, adapt to the material. Eugen Belz, technical manager at Schlenker: “This is a pneumatic system that is controlled by the machine. There is a constant pressure on the guide bush, for example 2.5 bar. If the material becomes larger or smaller, the guide bush adapts to the changed conditions. " Reaching over for rear processing In order to further optimize the bit production process and save cycle times, Schlenker has equipped the Swiss-type lathes with the Masa tool. The overgrip collet from the Masa makes it possible to overgrip turned parts with a diameter difference of up to four millimeters, regardless of the available path of the machine. This means that the subspindle can be viewed as a fully-fledged spindle. Depending on the geometry of the workpiece to be machined and the possibilities of the machine, this can lead to enormous savings in cycle times. The Masa Tool Microconic systems consists of a base body and, in this case, an over-grip collet in T-design. The use of this collet makes sense if the diameter to be clamped is smaller than the diameter to be overcome. This enables a concentricity of 5 μm. The system is used in the subspindle and can be precisely set on the machine. For this purpose, Schlenker provided the Masa Tool MicroGrad setting ring, whereby the closure of the microconic collet can be adjusted in steps of 0.02 mm. This setting is then held by the base body. According to Andreas Stengele: “Normal collets are adjusted by feeling. With the Microconic system, I can define exactly how far you tighten it for the ideal tension." The closed system is made of spring steel and is very flexible. "We have been offering the system for over two years and have not yet seen a break," emphasizes Eugen Belz. Minimize cycle and changeover times Without the Microconic solution, processing would alternatively only be possible in two stages, which ties up more capacities and employees - because Wiha does not manufacture unmanned. “It's always about saving yourself the second or third step,” explains Daniel Schanne. The aim is to reduce lead times in order to get the product to the customer faster. In this way, more than a quarter of the cycle time could be saved in the small parts series. The family business has also organized its production in such a way that ideally only one bar diameter is machined on a sliding head lathe and therefore only the profile to be milled changes. Since the rear side remains the same and is spanned at the front, the machines do not have to be converted, which is time-consuming. "In order to mill the most varied of screw profiles, you only have to change the milling cutter," says Daniel Schanne with satisfaction. To view the original article click here.  "The Microconic System provides extreme concentricity, incredible accuracy, fantastic rigidity, and has a unique micrometer style locking system so you can clamp on the most delicate part without crushing them. You can hold a fragile part solidly in place allowing the sub spindle to do things like broaching or heavy drilling that isn't always possible."Read more below!

PMTS 2019: Masa Tool’s F37M10 cartridge is said to replace the standard TF37 collet in a users CNC spindle. #PMTS Masa Tool’s F37M10 cartridge is said to replace the standard TF37 collet in a users CNC spindle. This enables the use of the company’s Microconic collets to achieve concentricity within 5 microns (0.0002"), according to the company. The cartridge is a micro-workholding system for use in high precision, small diameter CNC turning applications. This cartridge is compatible with spindles that accept DIN 1536E, Meister Swiss 563, Schaublin F37 (76-740), Southwick and Meister TF37, KEB (MasWerks) MC37 and Hardinge TF37 / 4619 collets. The company’s cartridge and collet assembly is designed to vector the chucking force directly over the holding surface. This means the chucking force is reduced while at the same time the holding power is increased. This is said to open up the possibility of moving part operations to the sub-spindle and reducing cycle time. Also, the cycle time is commonly reduced by 20-40 percent.

Designed for the clamping of micro-workpieces in the sub-spindles of sliding-head turning machines, Floyd Automatic Tooling, in association with Masa Tool of the USA, has released the Microconic system into the UK marketplace. The Microconicworkholding system consists of a cartridge and precision collet. Importantly, no machine adaptations are required: the collet fits inside the cartridge and is adjusted before being fitted directly into the existing collet sleeve.  Microconic workholding system available from Floyd Automatic in the United Kingdom Microconic workholding system available from Floyd Automatic in the United Kingdom With a concentricity level of between 3 to 5 µm, Microconic is suitable for sliding-head lathe marques including Tornos, Citizen and Star. It is currently available for F20 and F25 style collets, with F37 versions in development. A 5C version can also be offered. The cartridge system incorporates a solid extended nose and has the facility for micron-adjustment of the collet closure. To confirm precision levels, the hardened and ground cartridges can be used as gauges to verify spindle accuracy. Masa’s Microconic also includes ‘over-grip’ collets where clamping behind a shoulder is necessary, for example. The cartridge/collet combination can accommodate openings more than 4 mm larger than the clamping diameter (depending on the application). This flexibility offers production engineers the potential to machine the part the other way around, which can sometimes help improve cycle times. Microconic collets are available in 0.05 mm increments from 0.22 to 10 mm diameter. Each collet has a nominal clamping range from 0.05 to 0.1 mm depending upon the chosen collet diameter. With regard to the over-grip collets, the nominal clamping diameter starts at 0.5 mm with a maximum clamping diameter of 7.2 mm. For further information www.floydautomatic.co.uk  This article originally appeared in Machinery Trade International Masa Tool’s Microconic T-type over-grip collet features a longer gripping surface for holding longer parts. Masa Tool’s Microconic T-type over-grip collet features a longer gripping surface for holding longer parts. The collet can open as wide as 3.5 mm (0.138") over the chucking diameter and runs within 5 microns (0.0002") TIR.  Microconic T-Type collet on display at IMTS 2018. Microconic T-Type collet on display at IMTS 2018. The collet is designed for use with longer parts such as bonescrews with wide-pitch threads; orthopedic surgical drills and taps; long shafts with flange; long, thin-walled tubular parts and long plastic parts. Extra spread is required to open the collet wide enough to go over the larger diameter. The correct over-grip collet for a specific part can be chosen based on grip diameter, width of the grip land and the largest diameter of the part. According to the company, the collet expands machine capability, eliminates secondary operations and reduces cycle time. It features a standard gripping land length of two-to-three times the diameter. It is available with diameters ranging from 1.55 mm to 7.2 mm (0.061" -0.283"). The collet is said to grip with the same rigidity and accuracy as regular collets and features a fatigue-tested design built to last more than 250,000 full-load cycles. The collets are compatible with the company’s cartridges and come with its Microguide Brass ejection guide sleeve blank. |

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2024 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed