|

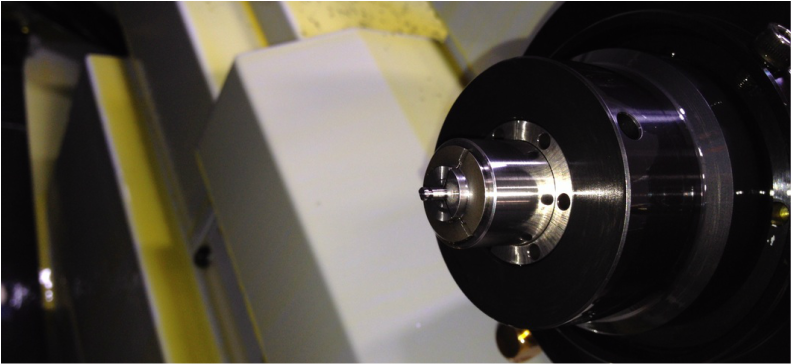

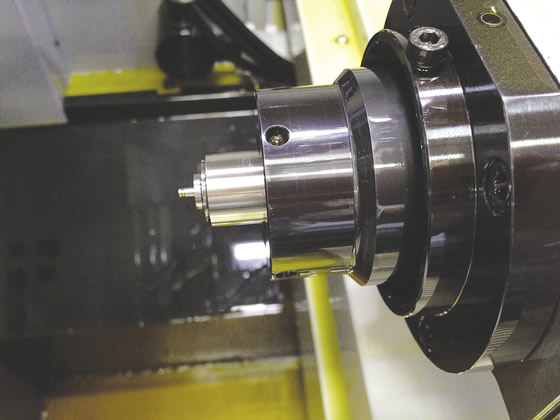

Matt Saccomanno, the inventor of the Microconic Workholding system discussed how it works at IMTS 2016. Masa Tool has developed the Microconic™ system specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck. The system consists of two major components: The Microconic™ cartridge, which fits into your CNC machine spindle replacing the standard 5C, TF20 or TF25 collets, and the Microconic™ collet, which fits in the Microconic™ cartridge. The Microconic™ system has unsurpassed concentricity: Our manufacturing tolerance is 3µm (.0001") and we guarantee our cartridges to be within 5µm (0.0002") in production use in your machine. The Microconic™ system works with either draw-type or push-type standard collet systems that are in any machine. The Over-grip collet capabilities of Masa Microconic™ System, introduces a whole new world of time saving opportunities awaiting. Our Overgrip Collets open up to 4mm (0.157") diameter larger than the clamping diameter.

1 Comment

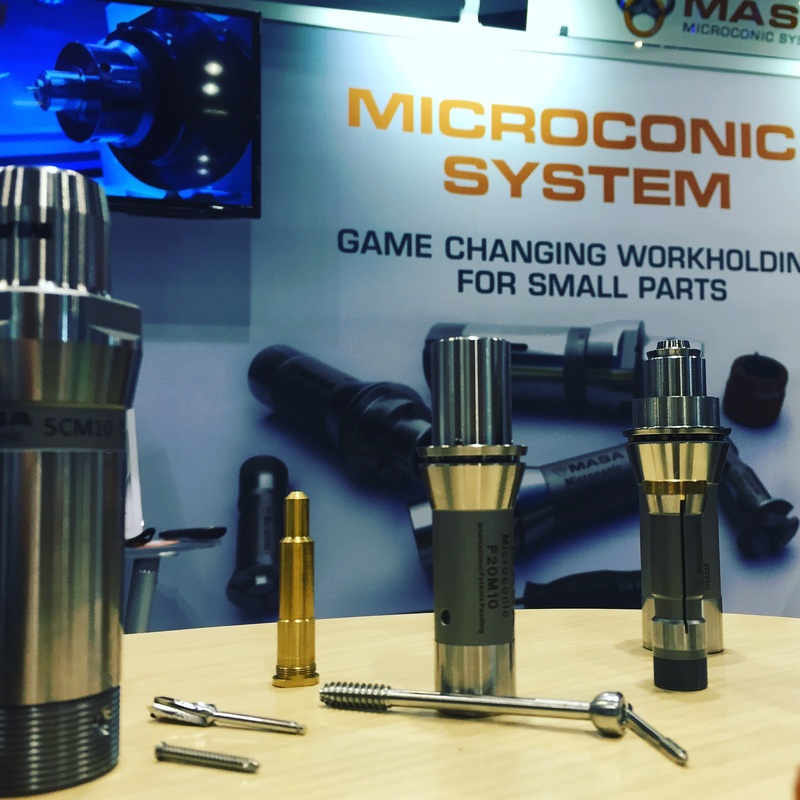

Our first IMTS show was a tremendous success! We got to meet many many new customers and where very pleasantly surprised by all the industry media people who stopped by to visit us at the show. We had an awful lot of people comment on the "Game Changing Workholding for Small Parts" by asking us "What's so game changing?" After they learned about the entire Microconic system we often heard them say "Wow! This is REALLY a game changer!!"

On Thursday, Harry Moser from the Reshoring Initiative visited us and we talked about how our products where developed right from our experience on the shop and because of the machining that is done locally in the Oceanside area. The video was posted live on our Facebook Page and you can find right here down below on the left.

Be sure to keep an eye our for some articles in some pretty big name magazines in the next few months. We're now on the look out for some application stories for them based upon the success you've had with our product. If you have a story to tell us be sure to leave it in the comments below or contact us so we can get all the details!

Make plans now to visit Masa Tool at the IMTS 2016 Booth W-2232 and learn about our new Microconic Workholding System.

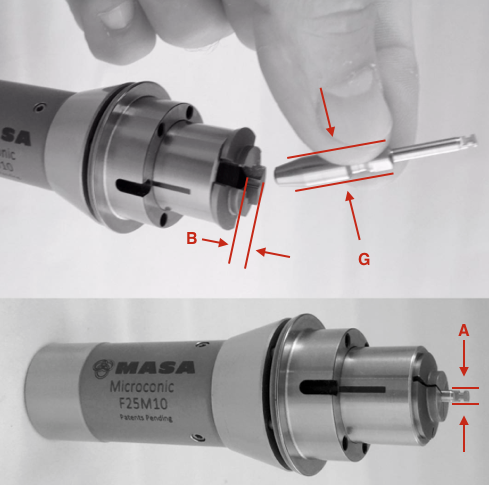

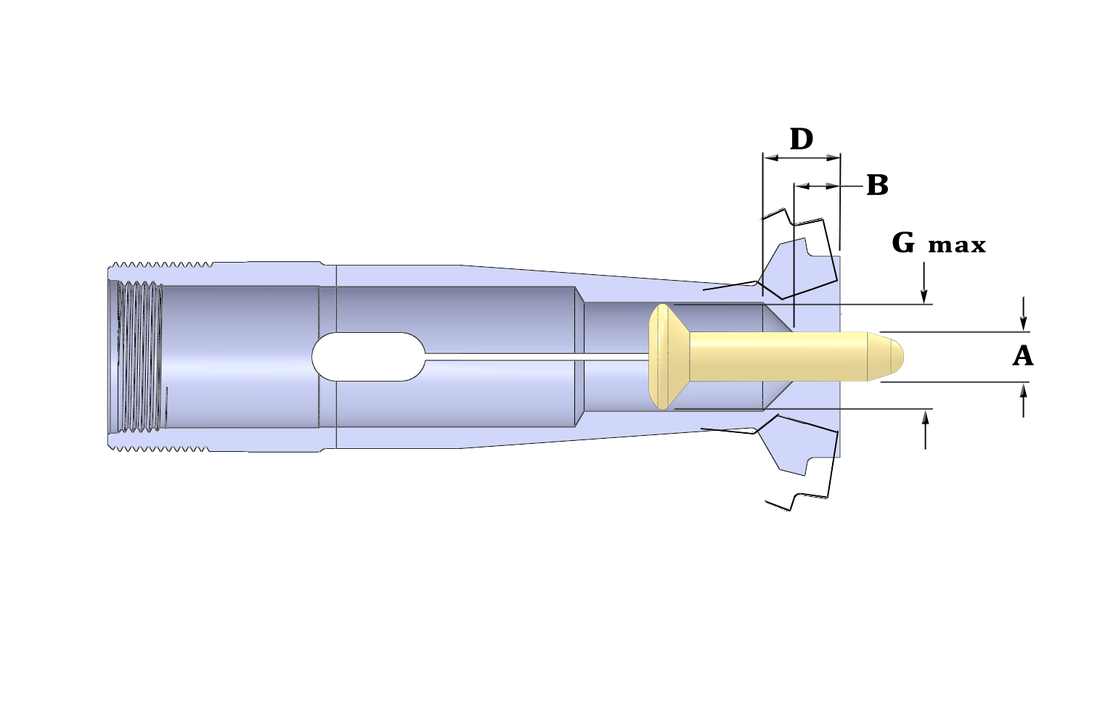

The Microconic™ work holding system is a mechanically actuated micro-workholding system for use in high precision, small diameter CNC turning applications. The system consists of two major components: The Microconic™ cartridge, replaces the standard TF20 collets and fits into your CNC machine with no modifications to the spindle required. The second component to the system is the Microconic™ collets which have capacities of 0,22mm - 10,00mm ( 0.0086" - 0.3949") and -Over-Grip collets which can open up to 4mm over the chucking diameter and run within 5 µm/.0002" TIR It's the first and only workholding system for the micro-machining industry. Masa Tool has developed the Microconic™ system specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck. The system consists of two major components: The Microconic™ cartridge, which fits into your CNC machine spindle replacing the standard 5C, 16C, TF15, Tf16 TF20 , TF25 or TF37 collets, and the Microconic™ collet, which fits in the Microconic™ cartridge. Part of the standard offering of Micrconic™ collets is the UM10W Over-grip series. The UM10W over-grip series is offered in the coverage range from Ø0.5mm - 7.2mm diameter (Ø0.020" - 0.283").

Masa Tool Inc. has created a precision collet device for the micromachining industry. The “Microconic System” is a miniaturized collet system that consists of two major components: the Microconic “cartridge” that fits directly into Swiss spindles like a collet and the Microconic collet that is a “right size” style collet. This chucking method is available for both draw-type (5C) and push-type or “dead length” systems (TF25), used on the subspindle of Swiss CNC lathes. The Microconic grind provides extreme accuracy, high gripping force and tolerance for workpiece size differential, the company says. Each finger of the collet has a separate conical surface that acts to apply the gripping force with accuracy.

When you need to make small parts, the size range of the 5C collet is where the best variety and value exist in machine tools and accessories. You don't want to sink capital into expensive, specialized machinery that will run nothing but small parts. But a 5C collet is pretty big compared to your 1/8-inch diameter part. An adapter is available, however, that renders a common 5C machine tool capable of handling very small diameter parts. The new small parts adapter, manufactured by Masa Machine Tool Accessories, Oceanside, California, fits in any machine's 5C collet closer, just like a standard 5C collet, without any modifications or special mounting procedures.

|

AuthorHere you will find the latest press releases, news coverage and technical information about our Microconic™ system Archives

February 2023

Categories

All

|

| Masa Tool | breaking news |

|

© 2023 Masa Tool Inc.

Microconic™, Micrograd™ and Microguide™ are trademarks of Masa Tool. All Rights Reserved. |

RSS Feed

RSS Feed